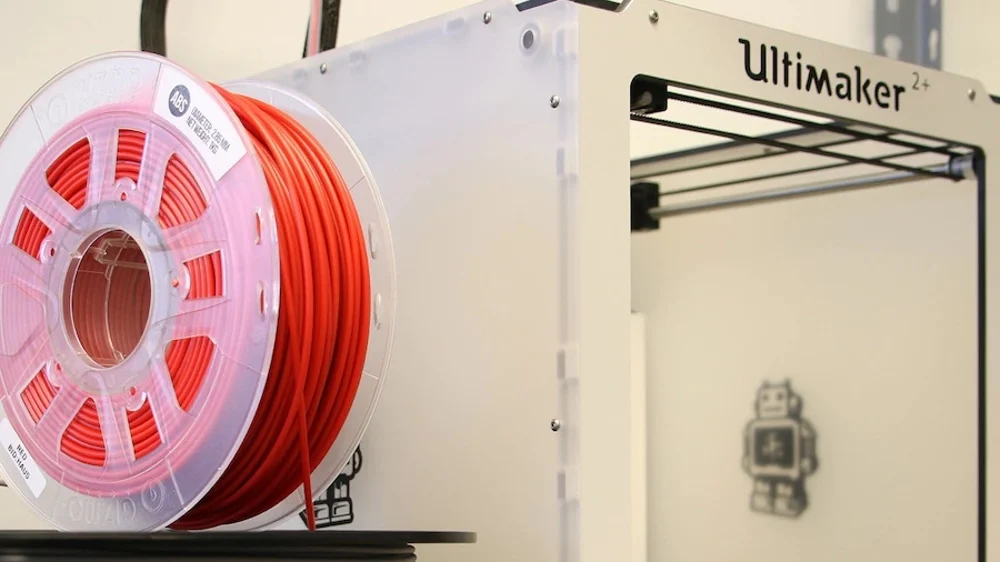

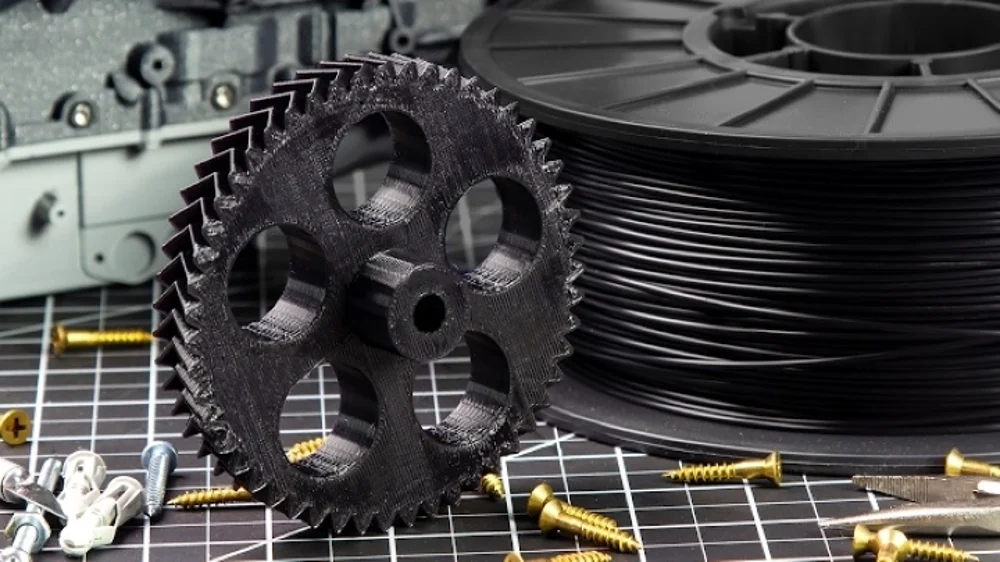

ABS is the most-used home 3D printer filament after PLA. Check out our guide to the best ABS filament brands on the market.

You most likely already know ABS. It’s probably the most popular plastic for injection molding, so you find it everywhere! Pipe systems, musical instruments, home appliances, keyboard caps, Lego, canoes, and even flat-screen TVs and computer monitors.Acrylonitrile butadiene styrene (ABS) is clearly one of the most-used plastics. It was first available in the 1940s and was initially marketed as an alternative to Bakelite. But it wasn’t until the 1950s that it became the go-to plastic worldwide.

ABS is made from the monomers extracted from petroleum. While its increased toughness over styrene made it suited for many applications, its limitations led to the introduction of a rubber (butadiene) as a third monomer in addition to acrylonitrile.

Today, it’s invaluable across many industries, as it’s easy to process and easily machined. Common machining techniques include turning, sawing, drilling, milling, die-cutting, and shearing. Uncolored, it has a yellowish tint and is usually delivered in small pellets for industrial use.

3D Printing ABS

As a thermoplastic polymer, ABS melts and cools without altering its chemical properties. That makes it an interesting 3D printer filament, even more considering the relatively low temperatures required for melting.

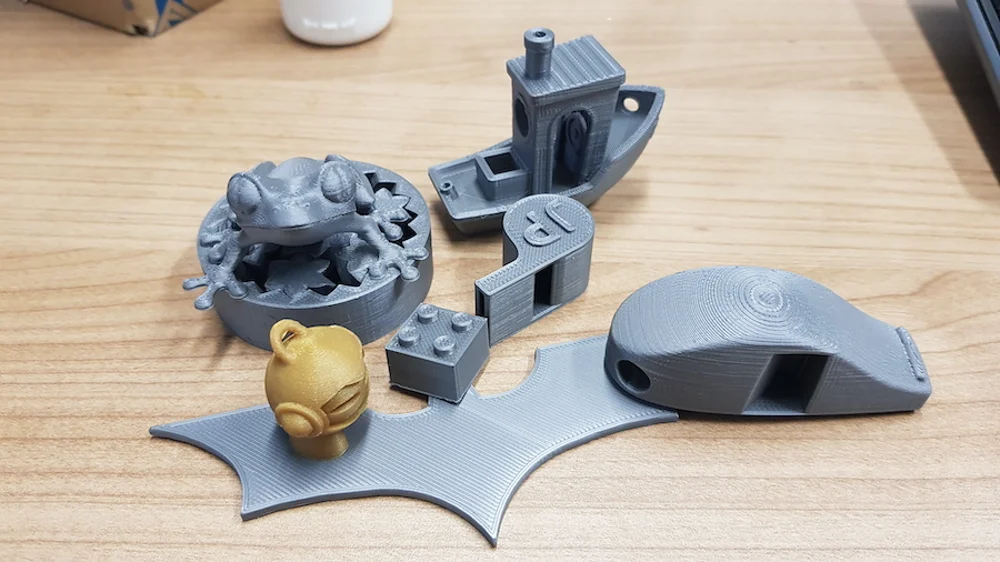

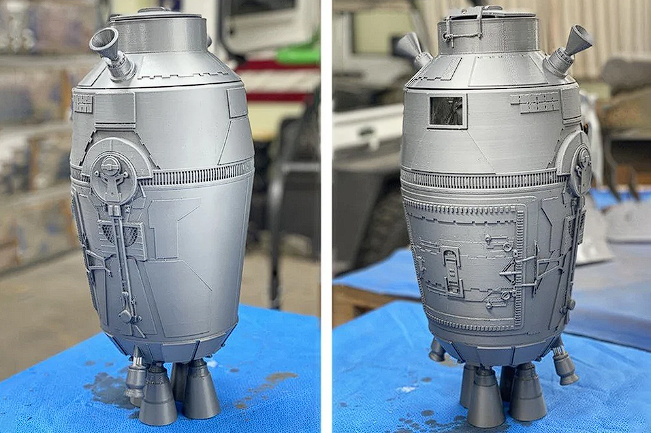

ABS was the most popular material for 3D printing until PLA arrived on the scene. Still, it remains one of the best material choices for printing affordable, durable parts, being especially relevant in commercial applications such as rapid prototyping.

In addition, ABS provides excellent quality finishes when handled properly, which by itself is a challenge for many. It’s also suitable for use in relatively high-temperature applications, for example creating 3D printer parts.

Pros

- Good mechanical properties: The material is known to be strong, tough, and durable. It’s forgiving to scratches and offers good resistance to heat, electricity, and everyday chemicals. ABS is a bit flexible and therefore less brittle than PLA. Try it yourself: Move a strand of ABS filament and it will distort and bend before breaking, while PLA will break much more easily.

- Easy to post-process: ABS is much easier to file and sand than PLA. It can also be post-processed with acetone vapor, which completely removes all layer lines and provides a clean smooth surface finish.

- Cheap: It’s one of the cheapest filaments around, with a 1-kg spool starting as low as $16. ABS offers a great value considering its superior mechanical properties, but be aware of the quality of the filament.

Cons

- Strong and toxic fumes: Smelly and toxic chemicals are released during ABS printing. While all filaments release ultrafine particles (UFP), ABS is known to emit a higher amount of dangerous volatile organic compounds (VOC) like styrene. Research shows that the particle concentration of ABS was 33 to 38 times higher than PLA. This could be addressed by printing in a properly ventilated room.

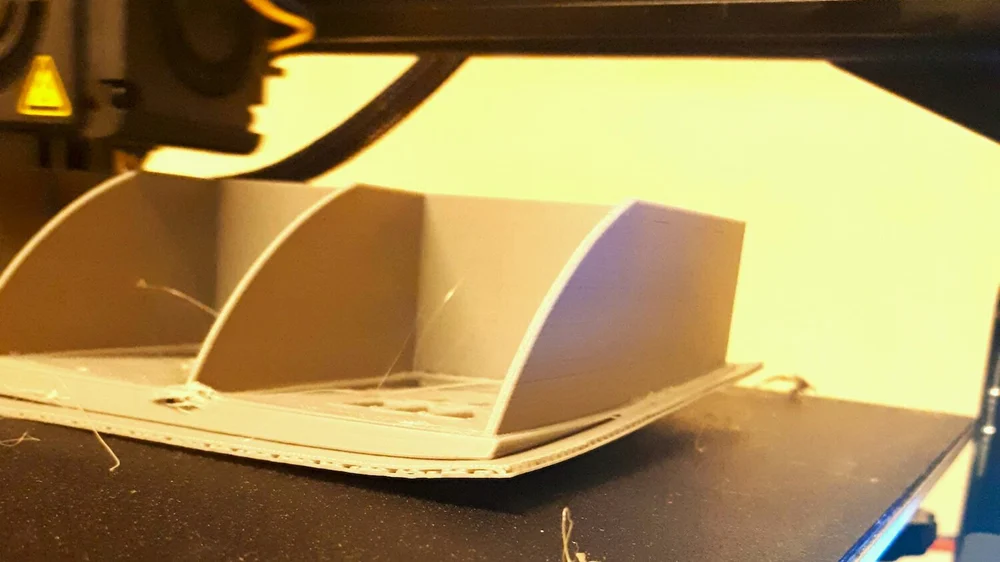

- Difficult to 3D print: ABS requires proper temperature management, as it must cool slowly to avoid cracks or split layers. Curling and warping are also an issue, especially for objects with a big standing surface and non-enclosed 3D printers. It absolutely requires a heated bed.

- UV sensitivity: ABS is UV sensitive, so it can sustain damage by direct sunlight. For this reason, it’s not really recommended to print outdoor parts with ABS. PETG and ASA are good alternatives for such applications.

Tips & Tricks

It can be quite a task for a newcomer to successfully 3D print quality parts with ABS. While no material is exactly the same and the specifications vary, there are a few things that should definitely help:

- Enclose the printer: ABS is sensitive to drastic temperature changes, so make sure your 3D printer is either enclosed (highly recommended) or at least that the temperature of the room is not cold. Avoid drafts as much as possible.

- Use a heated bed: This is mandatory. ABS has a high thermal contraction, so when the first layer cools down it shrinks in volume, causing deformations like warping. With a heated bed at around 110 °C, ABS remains in a sort of rubbery state, allowing it to contract without deforming.

- Proper bed adhesion: It’s highly recommended to use an adhesion agent on the build plate in addition to a heated bed. There are plenty of options, including glue stick, Kapton tape, and ABS slurry, a liquid solution of ABS diluted in acetone.

- Fine-tune the cooling: The part-cooling fan blows air onto each layer for faster solidification, but for ABS, this can lead to deformation. Try adjusting the cooling settings for the bare minimum necessary for bridging and to avoid stringing. A good tactic is to turn off the cooling fan entirely for the first few layers.

As a final tip before talking about the best brands, ABS requires special care during storage, as it’s a hygroscopic material (meaning it absorbs water). Moist filament is a pain to use, so try as much as possible to store ABS in a dry container when not in use. Trust us, you’ll be glad to skip the drying process!

So, now that we know what we’re doing with the material, let’s look at the best brands on the market.

Hatchbox

Hatchbox is an American filament manufacturer that offers a handful of quality 3D printing materials. Hatchbox’s ABS is one of its most popular filaments, especially for the price of around $20 per kilogram spool.

Our own review showed that Hatchbox ABS is of great quality overall and only slightly troublesome to print. The spools came well packed with a resealable bag and desiccant for storage between uses.

- Diameters: 1.75 mm, 2.85 mm

- Spool size: 1 kg

- Recommended hot end temperature: 210-240 °C

- Recommended bed temperature: 55-85 °C

- Price: ~$23/kg

Polymaker

Polymaker is a Shanghai-based company that works solely with 3D printing filament. It offers a variety of rather special filaments such as PolySmooth and PolyCast.

Its PolyLite ABS is branded as a low-odor filament and is considered by users to be of high quality. According to Polymaker, it’s made of a special bulk-polymerized ABS with lower volatile content.

- Diameters: 1.75 mm, 2.85 mm

- Spool size: 1 kg

- Recommended hot end temperature: 245-265 °C

- Recommended bed temperature: 90-100 °C

- Price: ~$23/kg

Sunlu

Sunlu might not be the most well-known filament brand around, but its ABS is definitely among the best. It comes in 1-kg spools with astonishing 25 different colors available.

It’s manufactured with Sunlu’s clog-free patent and is dried for 24 hours straight before packaging in a special aluminum foil. It’s all quite impressive for such an affordable filament!

- Diameter: 1.75 mm

- Spool size: 1 kg

- Recommended hot end temperature: 230-270 °C

- Recommended bed temperature: 80-120 °C

- Price: ~$22/kg

Fillamentum

The Czech company Fillamentum is known for creating filaments that are considered unusual, to say the least. Some of the more out-there options include the color-changing Wizard’s Voodoo PLA and the Vinyl 303, a PVC-based 3D printing material.

Its Extrafill ABS line is straightforward enough, though, except by the naming: Each of the 13 colors comes with creative names such as Luminous Orange, Signal Blue, and Traffic Red.

- Diameters: 1.75 mm, 2.85 mm

- Spool sizes: 750 g, 2.5 kg

- Recommended hot end temperature: 220-240 °C

- Recommended bed temperature: 80-105 °C

- Price: ~$35/kg

Gizmo Dorks

Gizmo Dorks is a US-based filament brand that offers a wide variety of ABS material. Besides the great number of colors available (21 in total), the Californian company also has what’s called “specialty” materials.

There’s the color-changeable ABS that’s heat-activated, changing from blue to white or green to yellow, for example. The fluorescent ABS glows under UV light, and the conductive ABS can be used for a bunch of interesting projects.

- Diameters: 1.75 mm, 2.85 mm

- Spool size: 1 kg

- Recommended hot end temperature: 220-240 °C

- Recommended bed temperature: 110 °C

- Price: ~$22/kg

MatterHackers

Yet another California-based 3D printing company, MatterHackers is a widely popular source of parts, tools, printers, and its own filament brand, of course.

MatterHacker’s go-to material for the typical maker project comes from their Build Series ABS. But if you’re looking to raise the bar, their Pro Series ABS is a premium material with superior mechanical properties and good inter-layer adhesion, designed for both prototyping and end-use parts.

- Diameters: 1.75 mm, 2.85 mm

- Spool size: 1 kg

- Recommended hot end temperature: 230-240 °C

- Recommended bed temperature: 80-110 °C

- Prices: ~$21/kg (Build), $52/kg (Pro)

eSun

eSun is a huge Chinese 3D printing company with a huge range of filament options, from regular PLA to metal-infused plastics, engineering-grade PEEK, and of course, the beloved ABS+.

ABS+ differs from regular ABS, as it’s designed to reduce the thermal contraction and shrinkage – thus avoiding deformation such as warping. Some users suggest that it might require a higher nozzle temperature, but it seems to be well worth it.

- Diameters: 1.75 mm, 2.85 mm

- Spool sizes: 1 kg, 3 kg

- Recommended hot end temperature: 220-260 °C

- Recommended bed temperature: 90-110 °C

- Price: ~25/kg

Flashforge

Flashforge is a seasoned 3D printer manufacturer with a huge portfolio of both professional and consumer machines. The Chinese company is also known for providing quality 3D printing materials, and its ABS Pro filament is no exception.

According to Flashforge, the “Pro” line of ABS filament differentiates itself by offering improved mechanical properties and less warping. It’s also said to be low-odor. ABS Pro comes in 1-kg spools with a handful of different colors to choose from.

- Diameter: 1.75 mm

- Spool size: 1 kg

- Recommended hot end temperature: 220-240 °C

- Recommended bed temperature: 80-100 °C

- Price: ~$20/kg

IC3D

The American IC3D Industries was founded in 2012 as a RepRap 3D printer manufacturer. Today, it produces and sells filament as well as 3D printing services.

Based in Ohio, the company produces and sells regular ABS in spools as big as 10 kg! IC3D materials are high quality, and its ABS has a very low odor according to a couple of users.

- Diameters: 1.75 mm, 2.85 mm

- Spool sizes: 1 kg, 2.5 kg, 10 kg

- Recommended hot end temperature: 220-260 °C

- Recommended bed temperature: 110 °C

- Price: ~$35/kg

Overture

Overture 3D focuses on custom-designed 3D printing filaments. The American company offers a low-odor ABS with great quality and low warpage according to many users.

As an added bonus, every spool of Overture ABS comes with a special build surface for your 3D printer. It has a grid layout of 200 x 200 mm and provides excellent bed adhesion.

- Diameter: 1.75 mm

- Spool size: 1 kg

- Recommended hot end temperature: 245-265 °C

- Recommended bed temperature: 80-100 °C

- Price: ~$23/kg

Kodak

Kodak is usually associated with photography equipment and consumables. Yet, the American company has recently entered the 3D printing market with printers, software, and filaments.

All of its filaments are compatible with any 3D printer and are considered top quality. The Kodak ABS comes in a vacuum-sealed aluminum bag along with a reusable ziplock bag for storage between uses.

- Diameters: 1.75 mm, 2.85 mm

- Spool size: 750 g

- Recommended hot end temperature: 230-240 °C

- Recommended bed temperature: 95 °C

- Price: ~$33/kg