Polyvinyl butyral (PVB) is a special 3D printing filament that can be layer smoothed. Read on to learn all about PVB filament!

What Is It?

If you’re a fan of Prusa Research and all their latest 3D printing ventures, then you may have heard about their recent PVB Prusament filament. Polyvinyl butyral, or PVB, is a thermoplastic polymer commonly used in the backend of automotive parts like the interlayer between two sheets of glass on car windows.

PVB is certainly not one of the most popular materials in 3D printing, but Prusa didn’t make their own for no reason. As a material, PVB has a unique set of features that make it suitable for use as a 3D printing filament.

In this article, we’ll go over the features of PVB filament, comparing it to other materials to reveal this filament’s advantages and drawbacks. We’ll also go over how it prints and what the community thinks of it. Happy printing!

Printability

One of the most important features of any 3D printing filament is how well and easily it can be printed. To further examine PVB filament, let’s look into the material’s printability and a few of the properties that come with it.

Temperature

First off, one of the most important aspects is the temperature necessary to print it. PVB can be printed at fairly low temperatures, most similar to those of PLA and PETG. Usually, PVB filament requires a nozzle and bed temperature of around 215 °C and 75 °C, respectively.

According to Prusa Research, PVB’s melting point is comparable to PLA’s, and the lower temperature requirement makes it easier to print parts with more detail. This is most likely due to the heat deformations associated with printing at higher temperatures.

As we mentioned, PVB also requires a relatively low bed temperature of 75 °C, compared to the typical 100-110 °C needed for ABS. (The bed temperature of printing materials is usually close to its glass transition temperature, which is the temperature at which it starts to melt.) Therefore, PVB isn’t great for outdoor components that will be in the sun because it isn’t very heat resistant. According to Prusa Research’s technical data sheet, PVB has a heat deflection temperature of only 60 °C.

Other Factors

Second, PVB doesn’t require any specific hardware (neither an enclosure nor a direct drive extruder setup) to print well.

Third, PVB, similar to PETG, can also be considered a hygroscopic material because it tends to absorb a lot of moisture from the air, degrading the plastic’s performance. To combat this issue, we recommend drying your PVB filament before printing and using a dry box to store it. You can check out our article all about drying filament, as well as our piece on how to properly store your 3D printing materials to learn more.

Finally, we can’t forget the price of the material. PVB is definitely on the more expensive side of thermoplastic 3D printing filaments, costing around $50 per 1-kg spool. This is about double the cost of materials like PLA and ABS, but the different properties might be worth it, depending on what you’re looking to print.

Appearance

While PVB might not be as widely used in 3D printing and other fields as other plastics like ABS and PET, it still has many benefits. Many of PVB’s strengths are geared towards the visual elements of the material, making it an overall great filament for creating display pieces.

PVB is intrinsically transparent, which is well suited for making objects where light needs to pass through, like lampshades. Although PVB is naturally a very see-through material, parts 3D printed in PVB won’t come out as clear as glass as they do for car window interlayers. That’s because 3D printed parts can have features – such as infill structures and multiple walls – that obstruct the clarity of the object. In addition, PVB filament is not 100% PVB, so the same levels of transparency can’t be expected. To make parts clearer, you can try lowering the infill density and setting a larger layer height.

On top of being naturally transparent, PVB is also soluble with certain chemicals, significantly isopropyl alcohol (IPA). This means you can post-process parts printed in PVB using IPA or other chemicals to soften the part’s exterior, just like you can with acetone for ABS. Its chemical solubility provides two main benefits for the PVB material: bonding and smoothing.

The first benefit is bonding multiple PVB parts, as once two ends of PVB parts are softened, they can easily be joined. This capability makes PVB a great material for creating multi-part structures. Unrelated to solubility, PVB, like PETG, is also naturally a very adherable material, so getting it to stick to other surfaces should be easy.

The other advantage is layer smoothing. You can get smooth and glossy objects that look less 3D printed and more store-bought, perfect for making display items like jewelry, vases, and costume components. For PVB, layer smoothing can also enhance the transparency of a print, as seen in one maker’s video guide to this process.

Using a solvent is only one way to post-process PVB prints; you can also sand parts. However, according to Prusa, you have to use wet sanding to smooth PVB parts if you don’t have IPA. Wet sanding involves dipping a piece of sandpaper in water before using it, which makes the sanding process dirtier and longer than dry sanding.

Mechanical Properties

While being soluble makes for an attractive (literally) material, PVB is also in moderate mechanical standing compared to other 3D printing filaments such as PLA, PETG, and ABS. PVB is considered moderately strong for a thermoplastic but is pretty weak relative to materials like steel and PVC.

Despite this, PVB is still a great material for 3D printing and offers a few mechanical advantages over other filaments. According to Prusa Research’s material comparison sheet, PVB has a higher (better) tensile strength than ABS and PETG, meaning it can take more physical stress before snapping. PVB also has greater impact resistance than PLA and ABS and is even slightly flexible, although nowhere near as flexible as truly flexible materials like TPU or TPE.

Although PVB’s low melting temperature makes it a more easily printable material, it also contributes to worse mechanical properties. The low melting temperature results in PVB having poor layer-to-layer adhesion, which might mean prints are more brittle and more easily snapped.

Pros & Cons

Below, we’ve made a pros and cons list for PVB filament, to sum up the advantages and disadvantages of this material:

Pros

- Low warping

- Fairly easy to print

- Great for printing display objects

- Layer smoothing possible with IPA

- Moderately strong

- Easy to adhere other objects to

- Easy to paint

Cons

- Expensive

- Hygroscopic (absorbs water)

- Brittle (bad layer-to-layer adhesion)

- Low glass transition temperature

Results & Community Feedback

Overall, PVB seems to be a great material with a plethora of benefits, uses, and capabilities. Even if it looks good on paper, it’s important to look for community reviews of the material. In this case, when looking at PVB filament across brands, most users seem to prefer Prusament PVB and Polymaker PolySmooth PVB filament.

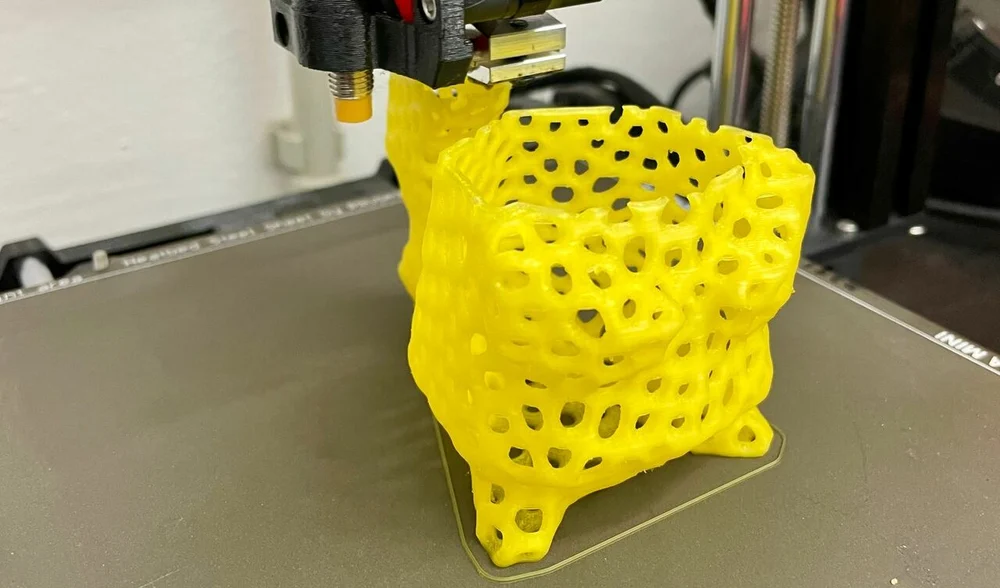

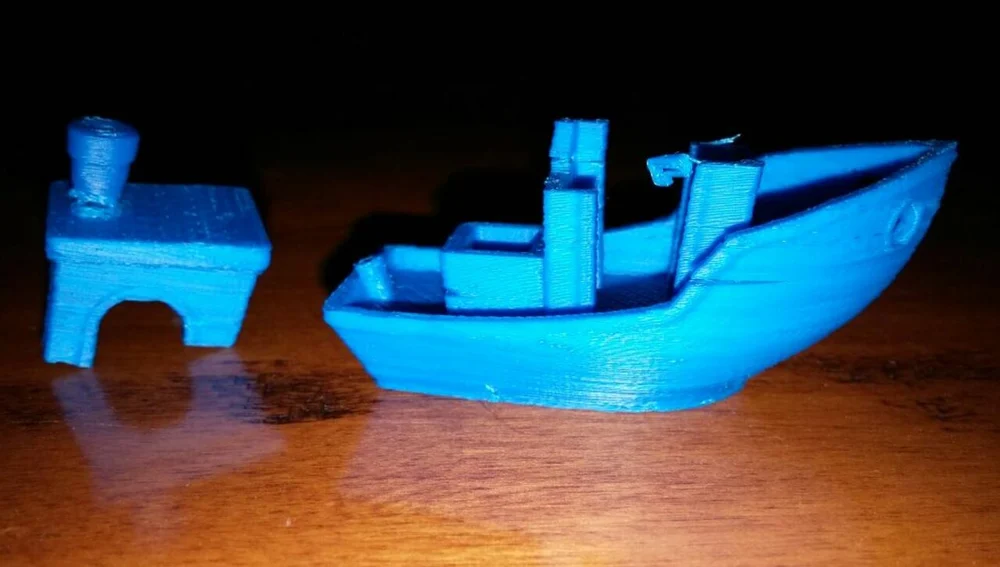

To start, based on images from online forums like the one seen above, PVB is capable of yielding excellent prints, especially when post-processed. Make sure to not use too much IPA (or another solvent) as one user found that excess can lead to cloudy prints.

Other users also had great success using a larger nozzle size, which is a capability of PVB that Prusa noted. One maker used a 0.8-mm nozzle to print a vase that they then layer smoothed with IPA, making for a super glossy print. Another user also showed off a similarly great vase printed with a 0.8-mm nozzle and a 0.4-mm layer height.

Lastly, once printed, PVB can be painted. Polymaker mentioned that you can use water-based and automotive paints to color prints made from their PVB filament. One user even discovered that using permanent markers works great for prints made from PVB. The maker also mentioned that the marker shouldn’t run or bleed into the print, even if you’ve layer smoothed it with IPA.