If you’re not quite clear on TPE filament’s rubber-like properties, check out this guide to learn the basics and discover the best brands.

TPE, or thermoplastic elastomer, is a category of rubber-like plastics that are great for printing anything that needs impact or vibration resistance, non-slip characteristics, or just plain old flexibility.

Used in dampeners, non-slip feet, phone cases, and the like, TPE deforms and compresses easily to counter loads, making it incredibly durable. Although sometimes tricky to print with, the results are often well worth the struggle.

In this article, we’ll go over some general printing and storage tips before jumping into our top picks of TPE filament. But first, we need to talk about TPE’s close relation, TPU.

What About TPU?

TPU, or thermoplastic polyurethane, is another common flexible material and is easily confused with TPE. So what’s the difference between the two (other than one letter)?

A simple explanation is that TPU is a type of TPE. That’s because TPE isn’t really one specific material; it refers to a range of elastic thermoplastics, of which TPU is one.

Recently, “TPU”, both as a term and as a material, has been gaining popularity over “TPE”. In today’s 3D printing scene, most flexible offerings are TPU-based materials, with TPE having fallen largely out of favor due to difficulties faced while printing.

To avoid any confusion, this guide will differentiate the materials based on technical hardness ratings. Flexibles rated at 90A hardness or below will be considered TPE, even if the material is TPU-based.

Given the few true non-TPU offerings available today, this way of differentiating the material categories is easiest. In the following list, you’ll see some items that are in fact TPU-based, but just soft enough for us to consider them to be TPE filaments.

Printing & Storage

Printing Tips & Settings

Being flexible, TPE has a tendency to buckle or squeeze through any gaps in the filament path. Make sure this path is well-constrained, with no gaps or obstacles. Towards this end, a direct-drive style extruder is recommended.

Retraction doesn’t work well with TPE due to its ability to stretch and compress. Disabling retraction is therefore recommended.

Some TPE is known to adhere too well to print surfaces. Use painter’s tape, a glue stick, or hairspray as a protective releasing agent.

To start, it’s recommended to use the following settings and set up:

- Nozzle temperature: 190-250 °C (varies)

- Bed temperature: Unheated-70 °C (varies)

- Print speed: 5-50 mm/s (higher in rare cases)

- Retraction: Minimize or disable

- Bed adhesion: Painter’s tape, glue stick, or hairspray recommended when unheated

Storage

TPE filaments are known to be hygroscopic, which means that they absorb moisture from the air. This can degrade the material, so any filament not in use should be stored in a low-humidity environment. An airtight container or bag with desiccant packs should do the job.

Top Pick: ColorFabb VarioShore TPU

Don’t worry, we know ColorFabb VarioShore TPU is TPU-based. But we include this filament as our top pick for a very specific and unique reason: its ability to vary density, and thus hardness, at varying print temperatures.

Hardness (Shore) variation is achieved via a foaming agent that’s incorporated into the material. It activates with heat and produces tiny, evenly-spaced bubbles in the print. To give you an example of how this works, this technology is widely used in the production of yoga mats.

The foaming only occurs at the hot end, so the filament still has TPU’s higher stiffness, and thus printability, at the extruder. This means that you’ll have the versatility of several filaments rolled into a single spool, with the ability to produce TPE-level softness with TPU-level printability.

ColorFabb also has some tips and tricks for using the foaming correctly when printing with this filament.

- Manufacturer: ColorFabb

- Price: ~€50 (~$55) for a 700-g spool

- Nozzle temperature: 190-200 °C for non-foaming, 200-250 °C for foaming

- Bed temperature: 20-40 °C

- Printing speed: 20-30 mm/s

- Flow: 60-100% (varies based on foaming guidelines)

Oldie but Goodie: NinjaFlex

Loved by thousands around the world, NinjaTek’s NinjaFlex has made quite a name for itself in the 3D printing universe. It’s satisfyingly soft, squishy, and non-slip – great for phone cases, dampeners, or even shoes! Although it’s based on TPU material, its 85A hardness puts it in the range of TPE-softness.

For a premium price, you’ll get premium colors and good printability (for a flexible, at least). It may not have fancy new foaming features, but NinjaFlex easily earns a top spot for its tried-and-true quality.

- Manufacturer: NinjaTek

- Price: ~$55 for a 500-g spool

- Nozzle temperature: 210-235 °C

- Bed temperature: 20-50 °C

- Printing speed: 10-35 mm/s

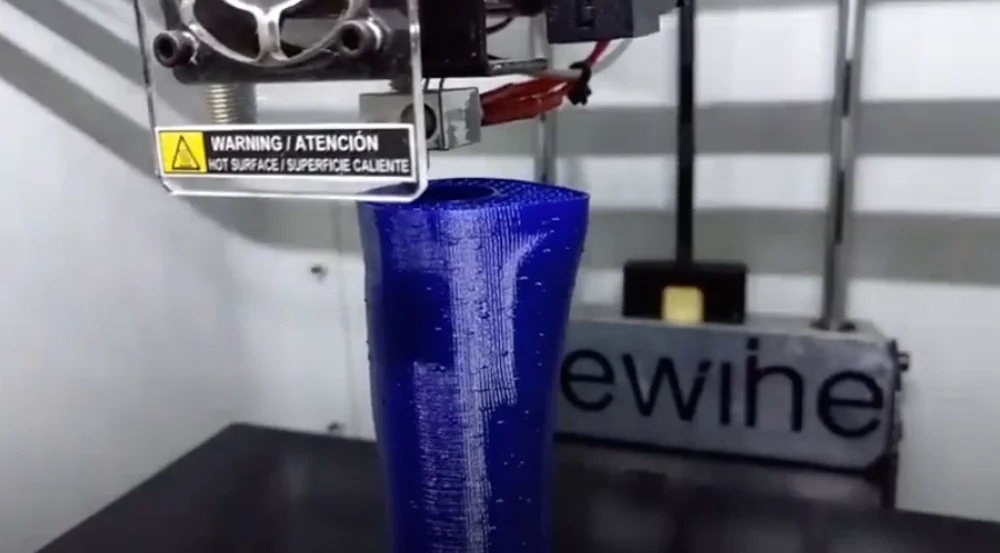

Colors Galore: Filaflex 82A Original

FilaFlex is the “flagship in the fashion world”, or so its company claims. Made by Spanish-based Recreus, FilaFlex has been a long contender in the world of flexibles, albeit not as widely available.

On paper, Filaflex 82A is very similar to NinjaFlex, though it’s slightly softer at 82A and marginally cheaper by weight. What sets it apart is its wide range of colors. Beware of FilaFlex’s extra stretchiness, which can make extrusion a bit tricky.

- Manufacturer: Recreus

- Price: ~€35 (~$39) for a 500-g spool

- Nozzle temperature: 210-240 °C

- Bed temperature: Heated bed not needed

- Printing speed: 20-110 mm/s

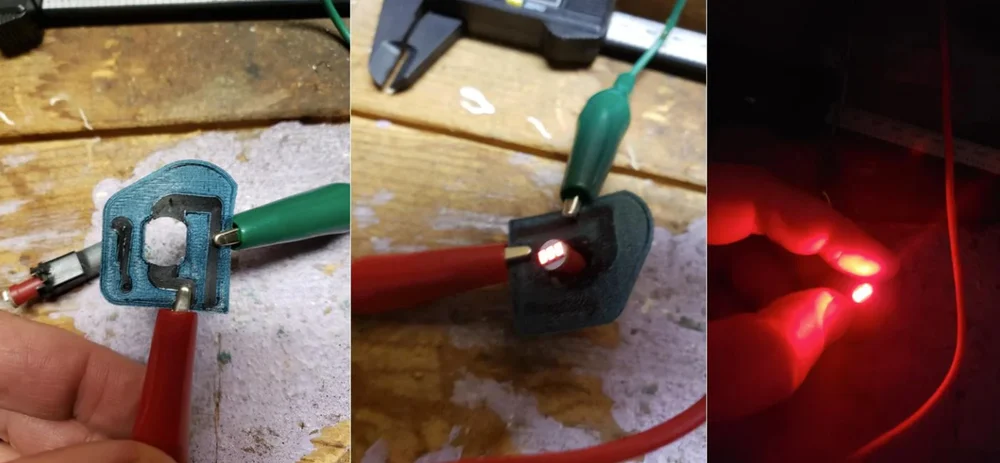

Conducts Electricity: NinjaTek Eel

From the same makers of NinjaFlex, NinjaTek’s Eel filament is a true rarity. Though limited to black and on the expensive side, it offers what other flexibles can’t: electrical conductivity.

This hybrid nature makes it great for conductive wearables, flexible electronic traces, anti-static grippers, and the like. Though technically TPU-based, its 90A hardness puts it at the top of what we’re considering TPE, striking a nice balance between printability and softness.

- Manufacturer: Ninjatek

- Price: ~$100 for a 500-g spool

- Nozzle temperature: 220-230 °C

- Bed temperature: 20-45 °C

- Printing speed: 15-60 mm/s

Super Soft: FilaFlex’s 70A Ultra-Soft

To finish off our list is FilaFlex’s 70A Ultra-Soft. This stuff is no joke: Tailored towards wearables and the shoe industry, it’s 70A hardness (or rather, extreme softness) puts it far out on the frontiers of consumer 3D printing.

For the ambitious only, the FilaFlex 70A Ultra-Soft is sure to get you one-of-a-kind results. Colors are limited.

- Manufacturer: Recreus

- Price: ~€45 (~$50) for a 500-g spool

- Nozzle temperature: 210-235 °C

- Bed temperature: Heated bed not needed

- Printing speed: 20-50 mm/s

Where Does that Leave Us?

In many ways, generic TPE has fallen into the shadow of newer TPU variants. TPE’s extra softness has outdone many and purchase options have plunged in number. But sometimes, you just need the extra softness and springiness that harder TPU just can’t offer. That’s when TPE shines.

If you’re feeling extra flexible (and brave), TPE’s squish and stretch surely won’t disappoint.