Ninjatek’s Armadillo filament is one of the toughest FDM 3D printing materials on the market. Join us as we take some Ninjatek Armadillo for a test ride.

What‘s Special?

The US-based filament brand NinjaTek is well known and respected in the 3D printing community. Parent company Fenner Drives concentrates on high-performance and specialty materials for industrial and consumer use.

Their flagship filament is NinjaFlex, specialists in flexible filaments with excellent 3D printing properties. NinjaTek also produces materials with special properties — like the industrial-grade flexible Cheetah and the sturdy, inflexible Armadillo, which we review here.

NinjaTek’s Armadillo is made from a Polyurethane derivate. These plastics are mostly used whenever you need things to get tough. It can be found in foam insulation panels, hoses, wheels and tires from roller coasters, escalators, shopping carts, elevators and even skateboard wheels. Also, these plastics are used in electrical potting compounds and in synthetic fibers (e.g., Spandex).

Armadillo is available in 1.75 and 3-millimeter diameters, and comes on 0.5, 1, or 2 kilogram spools.

Available Colors are red (“Fire”), orange (“Lava”), green (“Grass”), dark blue (“Sapphire”), white (“Snow”), clear (“Water”) and black (“Midnight”).

The price for a 0.5 kg spool is around $48.

The Verdict

We tested NinjaTek Armadillo filament on a Lulzbot TAZ 6. Our spool came in a recycled cardboard box. The content of the spool was covered with plastic foil to prevent it from absorbing moisture.

TPU is notoriously hard to print and needs some extra tender loving care — we have some additional tips here.

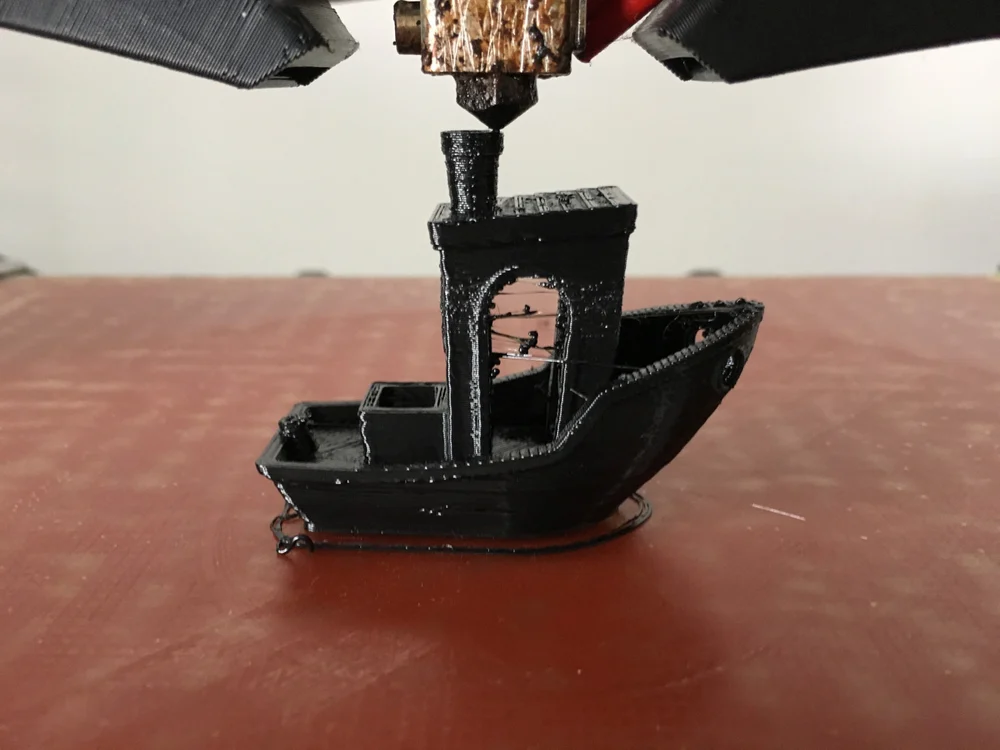

With the recommended settings from the Ninjatek website, our Benchy test print turned out only “okay”. You can clearly see some stringing inside the cabin.

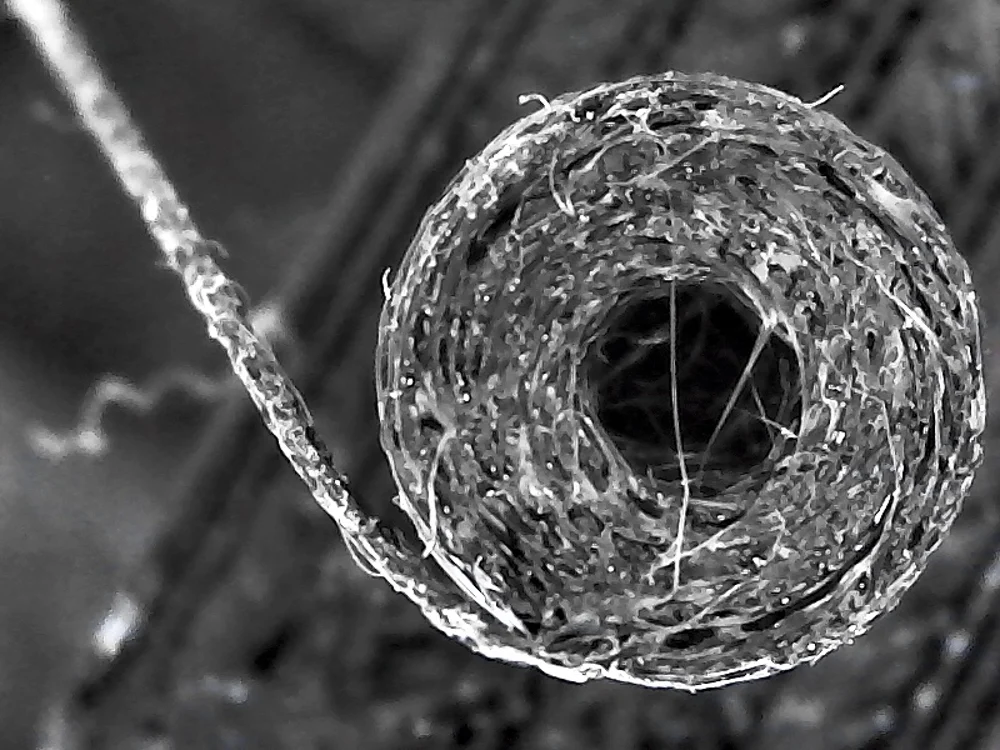

Armadillo material, in general, tends to be more viscous than PLA and even ABS. It may even keep coming out of the nozzle at the end of the printing process, as you can see under the microscope.

Our Armadillo Benchy ran into a bigger problem while printing the boat’s bow. Under the microscope, you can see clearly the layers didn’t adhere properly.

Other than these issues, the Benchy is passable. In addition, the color is consistent with a glossy shimmer to it.

Next, we printed two more models – the first one was the Predator Action Pliers. It’s a great, but somewhat difficult design to 3D print, as the whole mechanism is delicate. Printed in NinjaTek Armadillo filament, on the other hand, the model proved to be a breeze, turning out pretty much perfect using the standard specified settings for the material.

Stringing aside, the print turned out pretty awesome. The geared mechanism, which often breaks when pried from the build plate or gets “baked together” during the printing process, printed nicely with no issues.

As a final print, we ran with the two-part carabiner from Thingiverse. Again, Armadillo delivered a pleasing and rigid print.

All3DP’s Verdict

Even if we encountered some inconsistencies with our Benchy test print, we recommend Armadillo for anything that needs to be strong, durable and requires a high abrasion resistance.

NinjaTek says that Armadillo filament has 84% more abrasion resistance than PLA, 60% more than ABS, and up to 90% more than Nylon filaments. Also, it is known to be chemically resistant to substances such as Naphtha, Petroleum, and Freon.

The printing process itself was incredibly smooth for TPU – the 3D printing properties are amazing. Still, you should be prepared to tweak the settings to get optimal prints on your 3D printer.

If you are printing drone parts or heavily used tools, Armadillo will do the job. It is perfect for any outdoor types. Still, it’s not the best material to 3D print delicate parts, as it tends to be somewhat fibrous.

Specs and Settings

These are the setting you need to 3D print Ninjatek Armadillo. Polyurethane is more difficult to 3D print than PLA, so you might want to experiment with the setting suggested by the manufacturer. You can find the complete data sheet here.

PRINTER SETTINGS FOR NINJATEK ARMADILLO

Filament diameter: 1.75mm, 3mm

Print temperature: 220 – 230 °C

Bed temperature: Room Temperature – 45 °C

Suggested Printing speed: 15-20 mm/sec

Minimum nozzle diameter: 0,4 mm

How we Review

Friday is All3DP’s “Filament Friday”, where we take a spool of filament for a short test ride.

Every spool is brand new and unopened.

First, we 3D print a Benchy and check for any inconsistencies. Then we print one or two other 3D printables – and provide you with the results. Slicing is done in the latest version of Cura unless noted otherwise. The prints aren’t post-processed in any way; we just remove the support structures.

As for the printing settings, we take temperature and speed recommendations directly from the manufacturer. If the manufacturer offers a range, we go for the arithmetic middle. So if the manufacturer offers a range from 180-220 degree Celsius, we will set the printer for 200 degree Celsius (unless noted otherwise).

As a printer, we use a Prusa i3 Mk3 for 1,75 mm filament and a Lulzbot TAZ 6 for 2,85mm and 3mm filament diameter.

Of course, every spool is different. Even within a filament range, quality may vary. We‘re also aware that tweaking other settings like retraction can be the gap between a successful and a failed print. So if you own a spool of that filament, we would love to hear from you. Any interesting experiences? How did your prints turn out? Please feel free to add to the comments section.