CPE filament has a whole host of favorable properties. Learn what CPE is and how you can get started 3D printing it!

What Is It?

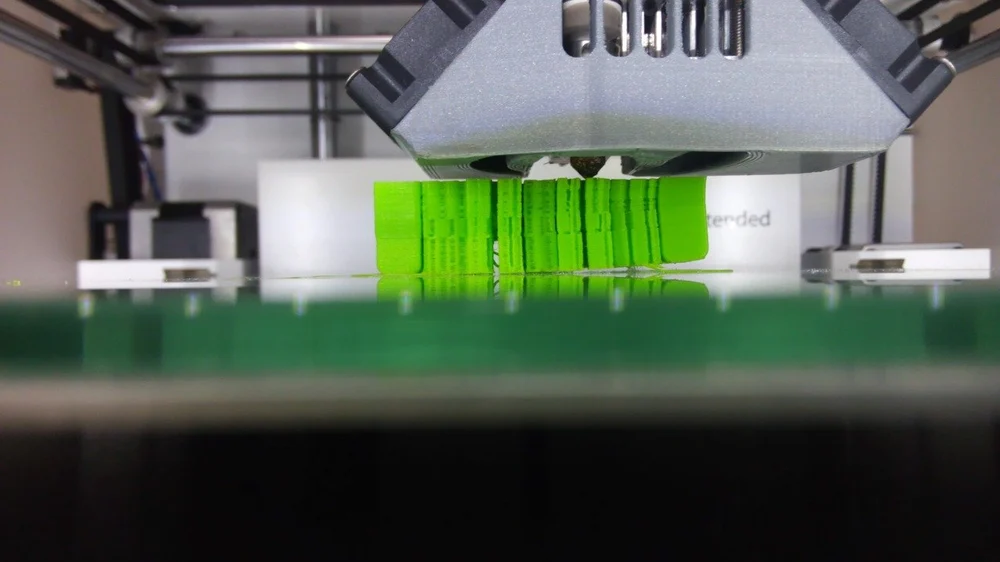

CPEs (co-polyesters) are very strong and versatile materials with growing popularity in filament form for FDM 3D printing. As printing material, CPE is highly durable, creating prints with high strength and intricate detailing. In addition, its layer adhesion is excellent with minimal warpage and shrinking. CPE has a wide range of possible applications due to being FDA-approved for packaging in the food and medical industries.

Here are its typical print settings:

- Nozzle temperature: 245–260 °C

- Heated bed temperature: 70–90 °C

- Print speed: 40–100 mm/s

- Bed adhesion: Blue tape, Magigoo, or glue stick

Please note that all figures may vary between different filament brands, and each manufacturer will have a base series of settings that they recommend you start from (to be tweaked as you begin to print using CPE).

It is also worth noting that all PETG filaments fall under the co-polyester category. The difference is PETG has added glycol, which remedies brittleness caused by crystallization when heating standard PET filaments. For this guide, however, CPE filaments specifically are the focus.

CPE vs PLA and ABS

To give a better idea of how CPE fares as an FDM material, here are a few points comparing it to popular materials PLA and FDM.

CPE vs PLA

- CPE has a much higher flexural strength than PLA

- CPE is more chemically resistant and water-tight than PLA

- CPE can be less prone to scratches or surface damage

- CPE is more difficult to print with

- CPE filament usually has fewer color options

- CPE cannot be smoothed with chloroform, unlike PLA

CPE vs ABS

- CPE benefits from greater flexibility

- CPE is more chemically resistant and water-tight

- CPE is safer in terms of fume emissions during printing

- CPE can’t be smoothed using chemical vapors (due to its resistance)

Ultimaker CPE & CPE+

Ultimaker’s CPE filaments have been developed specifically for use with their own hardware and possess some excellent characteristics synonymous with co-polyesters, such as:

- Excellent chemical resistance

- High impact strength

- High toughness and dimensional stability (massively reduced chance of initial layer warping)

- Good flexural strength (flexural modulus: 2100 MPa)

- Good tensile strength (tensile stress at break: 38 MPa)

- High impact strength (Izod tested to 95 J/m)

- High hardness (Rockwell 108)

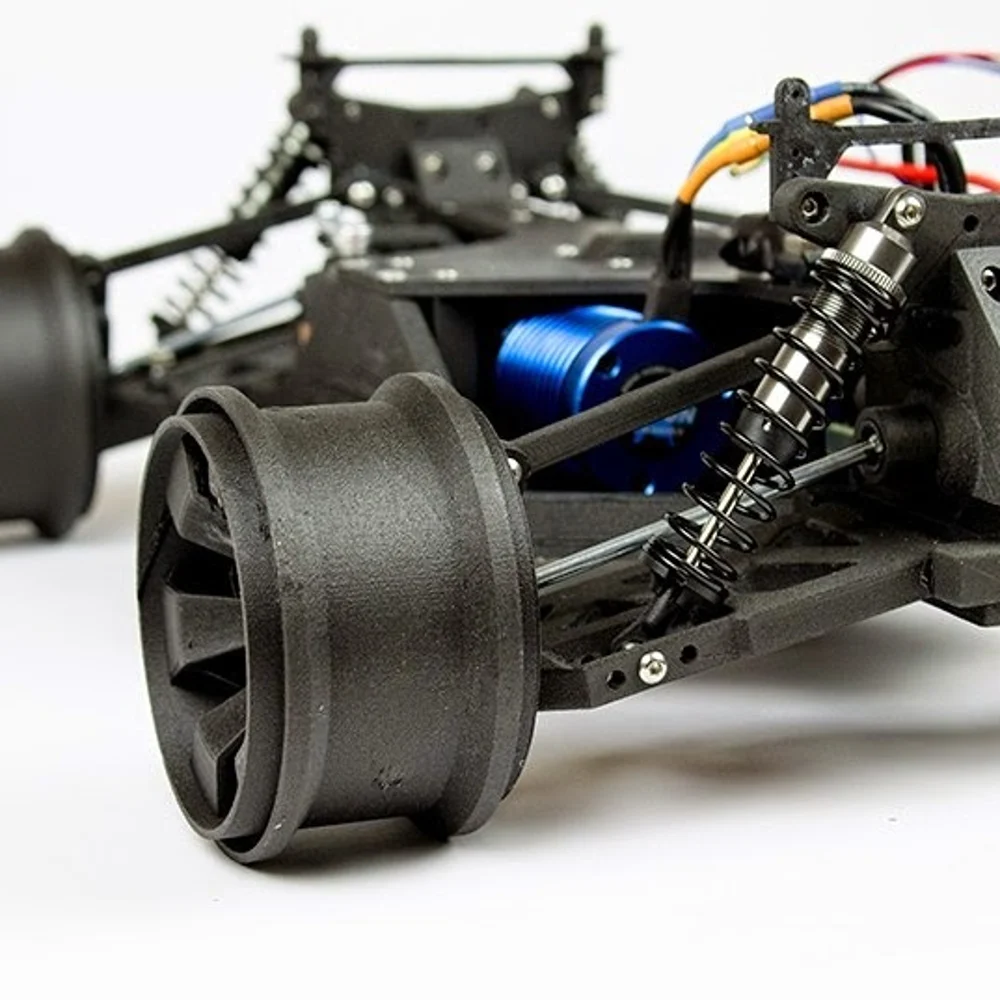

Applications include visual and functional prototypes (due to the great dimensional stability and detail), short-run manufacturing, and tooling, among others.

CPE+ expands on the original filament by offering increased temperature resistance up to 100 °C and an even higher impact strength (Izod tested to 860 J/m). Flexural strength (64 MPa) and Hardness (Rockwell 111) also increase with CPE+, but so does the price!

Fillamentum CPE HG100

Fillamentum’s CPE guarantees a high quality print with good functional properties. It’s made of a modified PETG material. Key qualities include:

- Long material life

- Excellent impact resistance

- Good layer-to-layer adhesion with no odor and very low warping

- Great tensile strength (47 MPa at yield) and flexural strength (71 MPa)

- High heat resistance

- Great optical properties, very high gloss and clarity

- Option to prime and paint neutral filament colors

Fillamentum recommends using Magigoo for bed adhesion with a bed temperature between 70 and 85 °C to give best print results, along with a nozzle temperature between 255 and 275 °C. They additionally guarantee workability of the filament for at least 12 months and recommend keeping the reel in its protective bag, when not in use.

ColorFabb, in collaboration with Eastman Chemical Company, has developed a range of co-polyester materials for use in FDM 3D printing. All of the available filaments are low-odor and styrene-free, and ColorFabb XT has been made with Amphora AM1800 to give the following key characteristics:

- High strength and very high toughness

- High glass transition temperature

- FDA food contact compliance and BPA-free formulation (makes it ideal for use in food and medical packaging applications)

ColorFabb XT comes in 13 different colors, including clear, and has also been reinforced with specially-sourced carbon fibers to create parts with a very high stiffness along with an aesthetically pleasing matte black surface finish. These fibers make up 20% of the filament’s composition.

XT is best printed using a heated print bed at around 70 °C but can be printed using a “cold” build plate through the use of blue painters’ tape, making sure it is perfectly level and the distance from the nozzle tip to the bed is correct for the first layer. It is then best to print with a brim or raft and disable the cooling fan for the first one to two centimeters to minimize warping.

ColorFabb nGen

ColorFabb nGen uses Amphora AM3300, a low-odor and styrene-free material with good melt stability through the printer nozzle, even at lower temperatures.

- Workable over a wider range of temperatures

- Advanced overhang ability and excellent finish

- Durable prints with winning combination of low processing temperatures and elevated temperature resistance (up to 85 °C)

Also in the nGen range are:

- nGen Lux: A special pigment in this material diffuses reflections, scattering light in all directions. This makes layer lines nearly impossible to spot to the naked eye, resulting in appealing parts without the need for any labor-intensive post-processing.

- nGen Flex: A semi-flexible material which can be printed at PLA-like speeds, also tough and highly temperature resistant (up to 130 °C).

Taulman3D T-Glase Filament

Taulman3D’s high strength T-Glase range is derived from PETT (Polyethylene co-Trimethylene Terephthalate), which is slightly more rigid than PETG. T-Glase’s name (shortened from “tough glass”) suggests a key characteristic: It produces prints that are colorless with good reflectivity.

- Optimal temperature for printing is 235–240 °C (note that the material will print down to 230 °C and up to 248 °C)

- Excellent initial layer adhesion to both heated acrylic and glass print surfaces

- Low glass transition value (78 °C), meaning it should not be exposed to high temperatures

- “Water clear” (no degradation to a color in multiple layers of application)

- FDA approved and 100% reclaimable (but not biodegradable like PLA)

It’s even possible to process T-Glase to make it look more like glass!

Winding Down

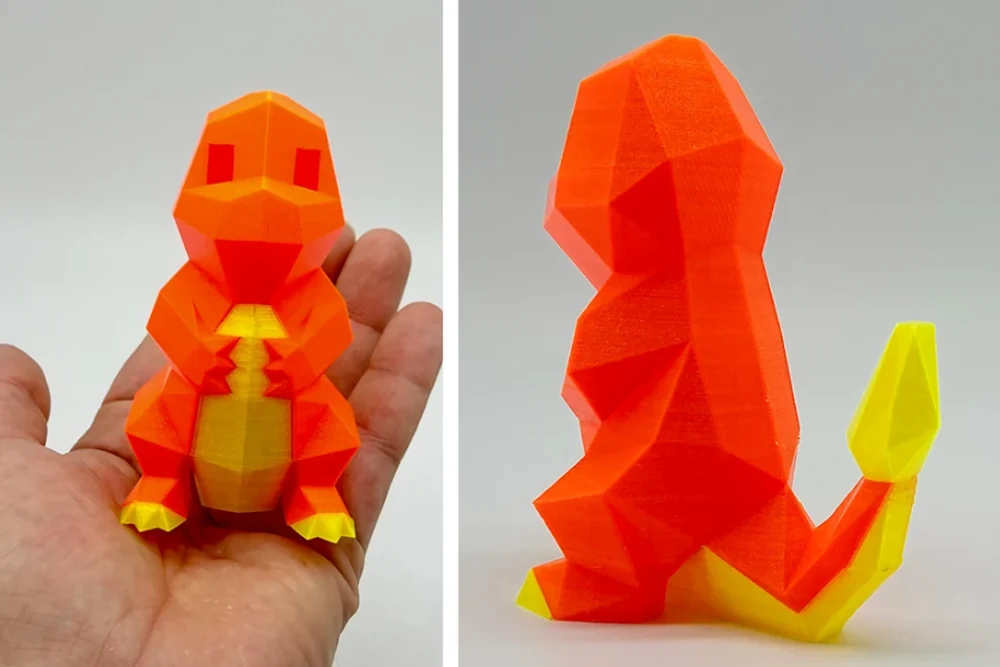

CPE filaments are becoming increasingly popular across a wide range of applications, from aesthetic models to flexible joints and functional parts. This is thanks to its durability and strength combined with excellent optical properties.

Check out other exotic filament types to expand your library:

Feature image source: ColorFabb

Source: https://all3dp.com/2/cpe-filament-simply-explained-brands-compared/