PLA is by far the most popular FDM 3D printing material. Get down to business with this quick rundown of its ideal print settings and applications.

Polylactic acid, or PLA, is by far the most popular FDM 3D printing material available, and for good reason. It’s relatively inexpensive, a breeze to print with, and comes in hundreds of vibrant colors and blends.

We’ve already broken down this incredible material with a full, all-you-need-to-know guide. But here, we’ll give you a quick rundown of PLA to get you up and running as quickly as possible.

Let’s get started!

Why PLA?

PLA is a plant-based, biodegradable plastic. Its popularity in 3D printing stems from its incredible printability and versatility.

Printing and Performance

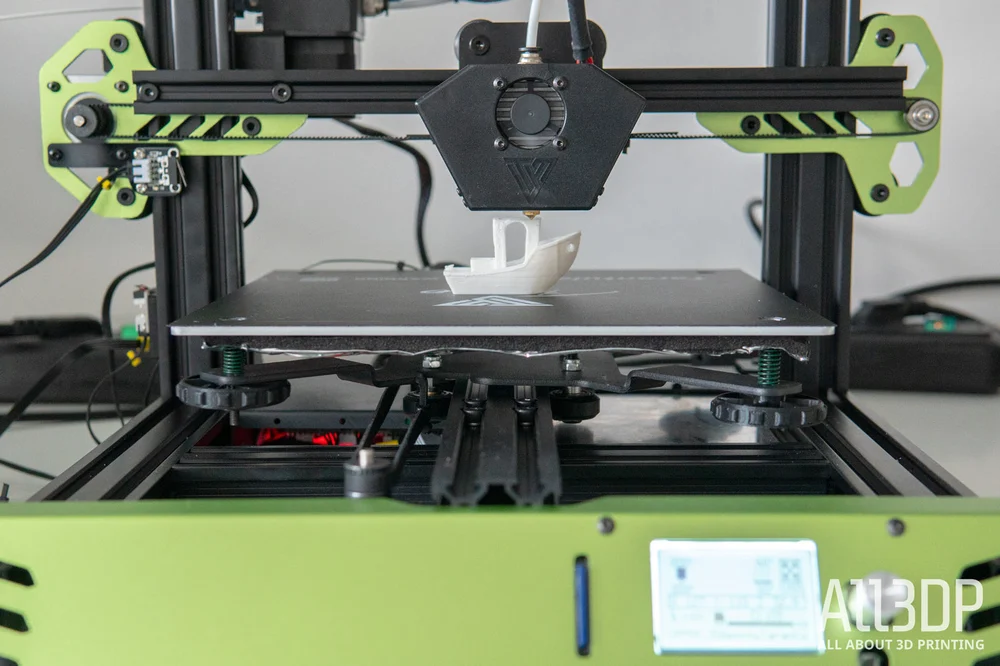

PLA is one of the easiest materials to print, unconcerned about having exact print settings. Temperatures are flexible, warping is minimal, and there are no strong print odors. For this exact reason, many people have only ever printed PLA. If you’re just getting into 3D printing, it’s a great place to start.

PLA is also known for its print quality. It has the best detail reproduction of the common 3D printing filaments, making it ideal for models where aesthetics are important. Easily taking pigments, PLA is also available in all sorts of vibrant colors and blends, as seen above.

For practical applications, PLA’s strength is also surprisingly ample for most light prototypes and models. Especially in recent years, PLA blends have gotten a lot better with respect to being durable. Many are even stronger than your standard ABS. Unless your application requires significant load-bearing and durability, PLA should serve you well.

External Factors

PLA is also preferred for those looking for a more environmentally-friendly plastic. PLA is based on plant matter, making it biodegradable (given some time with microorganisms and humidity). Its biodegradability isn’t enough to degrade printed parts in normal room environments, but it will allow them to decompose, if necessary.

Finally, with PLA being so popular, you will be able to find it at all sorts of price points and in all sorts of blends. From $20 to $45 per spool, matte white to wood-filled, the options are neigh-on endless. There’s a PLA available for nearly every application.

Why Not PLA?

Of course, no material is perfect. PLA comes with a few drawbacks that prevent it from being the perfect, all-in-one material:

Durability

PLA’s temperature resistance is poor, to say the least. Different manufacturers and blends will yield different results, but most PLAs will soften somewhere between 50 and 60 °C. Forget using PLA for anything that will need to withstand fire, hot water, or even sustained, direct sunlight.

PLA’s biodegradability may also come as a double-edged sword where durability is concerned. In normal room environments, the effects of biodegradation won’t be particularly noticeable. Outdoor use, however, may quickly wear down PLA prints. Other materials, like ABS, ASA, and PETG, would be more suitable for these applications.

Food Safety

Finally, PLA is not usually considered food-safe. In its most natural state, it is, but this quickly changes as additives and pigments are added. Only certain blends are considered food-safe, and even with those, bacteria buildup in the print lines and defects remains a concern.

Printing PLA

As already mentioned, PLA is extremely flexible when it comes to print settings. As long as your bed is level, your printer is in good working order, and your settings are in the right ballpark, prints should (generally) succeed.

We go into the ins and outs of nailing PLA print settings in a separate guide, but for a quick reference, the following is what your settings should look like. (Note: If your printer comes with PLA print profiles, these should already be well-tuned.)

- Nozzle Temperature: 190–220 °C

- Bed Temperature: 0 °C (with blue painter’s tape) or 50–70 °C

- Print Speed: 10–100 mm/s (depending heavily on the printer’s capabilities)

As with other materials, make sure that your bed is level and clean before starting a print. If your prints aren’t sticking well to the print surface, you may need to dial in more specific first layer settings.

Post-Processing PLA

After the print comes off the print bed, PLA can be post-processed in a number of ways.

Removing Stuff

Sanding, drilling, filing, and tapping PLA is possible, but take special caution to avoid softening the plastic from heat. With such a low softening temperature, PLA easily deforms and gums up tools. When drilling, filing, and tapping, stop regularly to allow the print and tool to cool down. When sanding is necessary, try wet sanding (with wet sandpaper) to prevent overheating.

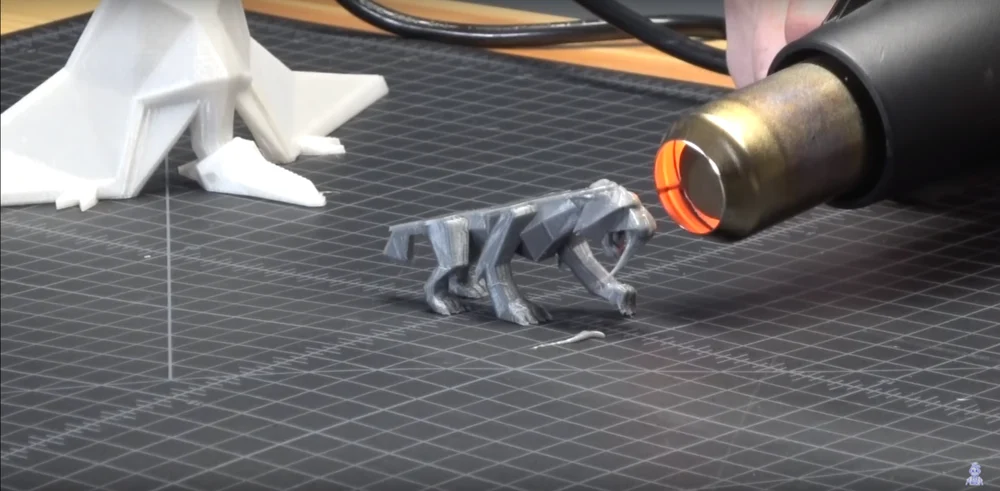

PLA prints can also be smoothed with a variety of methods. We provide a general guide that involves sanding, as well as one targeted specifically to those who don’t want to sand. The latter involves coating prints with glossy epoxies and finishes. Chemical smoothing PLA is possible but highly inadvisable due to the toxic chemicals involved.

Adding Stuff

Painting and gluing PLA is extremely easy. Most paints (spray paints, acrylic, etc.) and adhesives (superglue, epoxies, etc.) will work great, making PLA ideal for props and decorative parts. Even acetone welding, which YouTuber Thomas Sanladerer explores, is possible, providing a clean and secure chemical bond.

With regards to post-processing, PLA is quite a versatile material, with the only major downside being its sensitivity to heat.

PLA Your Problems Away

PLA is a great, allrounder in 3D printing. It’s easy to work with, incredibly versatile, and comes in a wide range of qualities and blends.

Hopefully, this guide got you up and running with this amazing material. For tuning specific PLA print settings, refer to our PLA temperature guide, and for more general troubleshooting, refer to our thorough troubleshooting guide.

Happy printing!

Feature image source: LeFabShop / Thingiverse