If you’re curious about the toughest materials to print with, read on to learn the strongest 3D printer filament types out there!

While 3D printing can be fun, the produced parts can turn out weak and not fit for purpose. Often, this is the result of using standard materials that aren’t designed for strength and endurance. The solution: Use a strong filament! Strong filaments can expand the possibilities of 3D printing, as you can print end-use parts for small projects without the fear of them breaking.

In this article, we’ll be exploring three of the strongest types of filament. Before that, though, we’ll detail what strength means in terms of filament materials.

If you need a strong 3D printed part but don’t have the means to print it yourself, try Craftcloud, your 3D printing service marketplace. You’ll be able to order your part in all the strongest filaments (and other materials) and can be assured of the professional quality of the end product.

Without further ado, let’s home in on these mighty filaments.

What Does Strength Mean?

Various factors can measure filament strength, but we’ll mostly be using tensile strength for this article, with references to elongation at break . The former measures a material’s resistance to breaking by being pulled apart and is useful for determining the overall strength of a filament. On the other hand, elongation at break describes how much the material stretches before breaking and is great for looking at impact resistance.

We’ll indicate each filament’s tensile strength using pounds or pounds per square inch (PSI). For the elongation at break of a material, we’ll give the percentage increase that a length of material can be stretched before breaking (this is mostly relevant for flexible materials like TPU).

Despite the clear number of pounds or percentage elongation that a filament can handle, there’s still a margin of error, depending on how a part was printed. We’ve gathered research from multiple sources to ensure that the reported results are backed up.

It’s also important to recognize that the material itself isn’t the only element of a printed part’s strength. Design, post-processing, and printing settings also alter a part’s strength, so be sure to make, print, and process your parts optimally.

Polycarbonate

According to multiple manufacturers and reviewers, polycarbonate (PC) is considered the strongest consumer filament out there. PC can yield extremely high-strength parts when printed correctly with an all-metal hot end and an enclosure.

By the Numbers

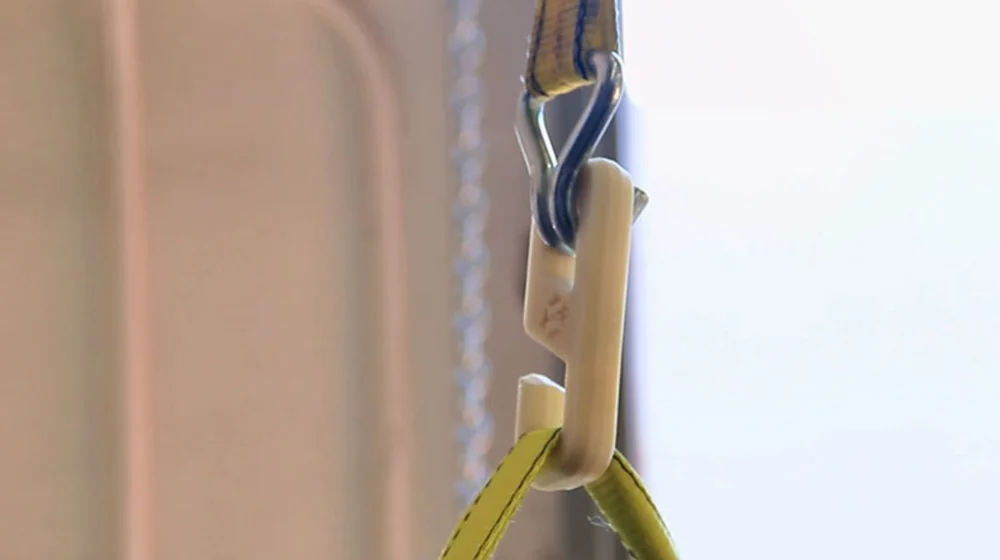

Airwolf 3D, after many filament tests, concluded that PC is the king of desktop 3D printer filaments. They were able to hang up to 685 pounds on a hook printed in PC and found that the material had a tensile strength of 9,800 PSI. In contrast, the same part printed in PLA could only handle 285 pounds.

Using a similar test, MatterHackers studied this type of filament’s tensile strength as well as a variety of other materials. They were able to hang an average of 409 pounds on a PC hook while PLA parts had a significantly weaker average of just 154 pounds.

Lastly, noted 3D printing YouTuber Thomas Sanladerer reviewed some PC filament and gave very positive feedback on the material’s strength.

Printing

Perhaps unsurprisingly, PC doesn’t print too well and doesn’t handle overhangs or fine detail the way other filaments do.

PC mainly comes in a transparent color and has excellent thermal resistance as well as impact resistance, according to Rigid.Ink. You’ll also need to print it at high temperatures, so make sure you have an enclosed printer and an all-metal hot end.

- Maximum hang strength: 685 pounds (using Airwolf 3D’s test)

- Pros: Super strong, great thermal and impact resistance

- Cons: Bad at handling overhangs and detail, requires enclosure and all-metal hot end, limited colors

Nylon

Next, we have nylon, another one of the most robust desktop 3D printer filaments out there. Nylon is a close second in strength to polycarbonate but still crushes the rest of the competition like PLA and ABS.

By the Numbers

A hook printed in nylon (910) filament had a tensile strength of 7,000 PSI, while the same hook in ABS only had a strength of 4,700 PSI, according to Airwolf 3D. Airwolf 3D also found that a clip printed in nylon filament was capable of holding 485 pounds.

MatterHackers found similar results and observed that a hook printed in their NylonX filament, on average, could hold 364 pounds before breaking. Rigid.Ink also reviewed some nylon filament and gave it a four out of five rating in strength and a five in durability. For some comparison, PLA had a rating of three for both strength and durability.

Printing

Nylon is a little bit easier to print in than PC, but this filament is still no PLA. Nylon filament is fairly hygroscopic, so it has to be dry and requires a somewhat high printing temperature of 220-270 °C. This material is prone to mild warping but also is impact-, fatigue-, and heat-resistant.

- Maximum hang strength: 485 pounds (using Airwolf 3D’s test)

- Pros: Impact-resistant, fatigue-resistant, heat-resistant, easier to print than PC

- Cons: Hygroscopic, warps, requires very high hot end temperature

TPU

Third, thermoplastic polyurethane (TPU) is a flexible material that can be considered one of the strongest materials. Although TPU filaments lack the tensile strength of PC and nylon, this material makes our list for being extremely impact-resistant, which stems from the plastic’s natural flexibility and elongation properties.

By the Numbers

In a test conducted by Airwolf 3D, a TPU 3D printed hook had a tensile strength of just above half that of the hook made of nylon. However, the TPU hook reached a 909% elongation at break, about sixty times the elongation of the PLA hook. This means that parts printed in TPU can stretch a huge amount before ever completely snapping or breaking.

A professional research study about medical uses of 3D printed TPU discovered similar results as Airwolf 3D’s, finding that TPU had a 702% elongation at break. The researchers also pointed out that this elongation makes TPU one of the most durable FDM 3D printing filaments.

Printing

Flexible filaments, including TPU, are notoriously difficult to print as filament can stretch when the extruder tries to push it, altering the diameter of the filament. It’s recommended to print TPU with a direct drive extruder as the less the filament has to travel from the extruder to the hot end, the better. It’s worth noting, however, that many users have successfully printed TPU with a Bowden-configured extruder.

As for TPU’s temperature requirements, it’s not too different from more standard printing materials like PLA and PETG. Just be warned that TPU, like nylon, is somewhat hygroscopic, so try to find an air-tight container to store any TPU filament.

- Maximum hang strength: Not provided by Airwolf 3D’s test

- Pros: Impact-resistant, flexible, standard temperature requirements

- Cons: Difficult to print, hygroscopic, needs slow printing speeds

Composites

Lastly, composite filaments, although not one single material, can be extremely strong. Composites are filaments with certain additives that influence the filament’s properties to enhance strength. These filaments typically have the word “pro,” “reinforced,” or “infused” in their names, as they’re usually a mix of different materials.

For this reason, we can’t tell you where composite filaments stand compared to the previous materials. Some composites, such as Carbonyte, can compete with nylon filaments in terms of strength, while some composites are weaker but offer other advantages.

It all depends on what the composite filament is made up of. The strong ones are usually a high-strength material like nylon infused with another high-strength material like carbon fiber or glass.

Speaking of carbon fiber, it too is a very strong filament by itself and is sometimes used to 3D print bikes. There are other composite filaments that are stronger than many pure carbon-fiber filaments, so it didn’t make our list, but it does deserve a special mention as a composite filament with a unique application.

By the Numbers

We’ll use carbon-fiber-infused nylon and glass-infused nylon filaments as examples. MatterHackers determined that hooks printed in these materials could hold an average of 349 and 268 pounds, respectively.

Rigid.Ink gave glass-infused nylon filament a four out of five rating in strength and a five in durability. They also gave carbon-fiber-infused nylon a five out of five on both strength and durability. For comparison, PLA and ABS both had a three in strength.

Printing

Composites vary in how they should be printed, but they tend to be relatively similar to their base material. Strong composite filaments are generally based on nylon, so you’ll need to print with some pretty high temperatures. These filaments are also generally quite expensive.

- Maximum hang strength: 349 pounds for carbon-fiber-infused nylon, 268 pounds for glass-infused nylon (using MatterHacker’s test)

- Pros: Combination of materials, strong

- Cons: Expensive, require high printing temperatures