Polypropylene is a plastic with a unique set of properties. Check out the best Polypropylene(PP) filament brands on the market!

Polypropylene, abbreviated PP, is a common household plastic prized for its unique set of properties. The material stands out for its translucency, as well as its resistance to chemicals and fatigue. Being food- and microwave-safe, PP is the perfect candidate for food containers and other uses around the house. Its incredible resistance to fatigue means that hinges can be made directly out of the material, so-called “living hinges”.

For 3D printing, PP is excellent for applications that need to be light, water-tight, or durable. Containers for food or liquids, as well as repeatedly bending clips and latches, are popular uses. Although PP is considered a food-safe material, keep in mind that food safety in 3D printing is a bit more involved than simply the filament’s material properties.

Printing PP comes with its quirks, so let’s explore how to print and store the material. After that, we’ll give you some good options if you want to get your hands on some filament of your own.

If you’re interested in printing a part in polypropylene but don’t have the means to do so, head over to Craftcloud by All3DP. You’ll be able to choose from competitive pricing options and have your order delivered right to your door.

And now, let’s get more into the wonders of PP.

Printing & Storage

Printing PP can be a challenge. With the right print settings, however, you can drastically increase your odds of success. Below are the basic print settings that we recommend:

- Nozzle temperature: 205-275 °C

- Bed temperature: 80-100 °C

- Bed surface: Clear packing tape

- Fan speed: 50-100%

- Enclosure: Recommended

The most important takeaways here are the bed temperature and the bed surface. PP is challenging for its tendency to come off the print bed, so these factors are key to a successful print.

In particular, we recommend using clear packing tape as the print surface because PP only likes to stick to itself. Common clear packing tape is usually made of PP, so covering your print bed in a layer of it just like you would with blue painter’s tape should do the trick.

Note that the print settings will vary by manufacturer, so we always suggest checking the specific recommendations for your filament before getting started. If you’re still struggling, we have a more detailed guide to succeeding with PP.

Storage

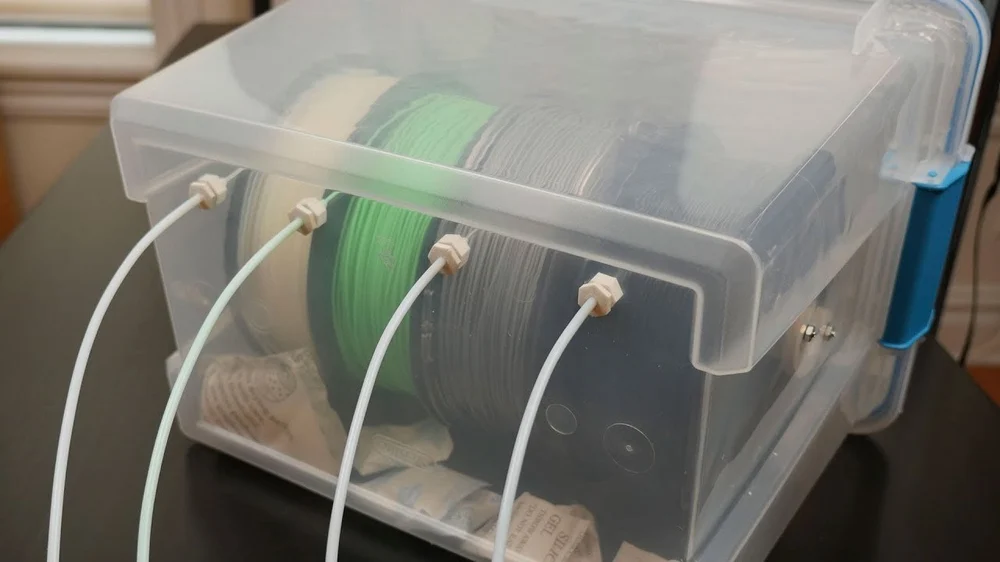

Frequently, you’ll hear that 3D printing filaments must be stored in dry environments. Thankfully, PP is not considered hygroscopic, meaning that it doesn’t easily absorb moisture. Therefore, you generally don’t need to be concerned about PP degrading with moisture, though we can’t speak for any additives that manufacturers may have used.

PP is, however, susceptible to degradation from UV light. As such, we suggest storing the material somewhere out of direct sunlight. To be absolutely safe, always store your filament as per our handy guide.

Fiberlogy

Fiberlogy is a Polish manufacturer of 3D printable filaments, including a polypropylene option that’s pretty affordable and available in a wide array of colors. Fiberlogy’s PP filament has very low bed temperature requirements and should work without a heated build plate. The company recommends the filament for printed containers, bumpers, toys, and even dishes.

Regarding its material properties, the seller states that Fiberlogy’s PP filament offers resistance to mechanical damage and great layer-to-layer adhesion. On this note, it’s worth noting that one customer mentioned their struggles with over-adhesion on glass build surfaces. In order to resolve the issue, they used tape on their build plate and are planning on using glue meant for polypropylene.

- Nozzle temperature: 220-250 °C

- Bed temperature: 0-80 °C

- Diameter: 1.75 mm

- Price: ~$35 for a 750-g spool (~$23 per 500 g)

- Colors: Natural, blue, graphite, gray, light green, orange, red, yellow, black

FormFutura Centaur

FormFutura’s Centaur PP comes in at a relatively good price, from a very reputable brand. This makes it a great first venture into PP, or just a great all-round filament.

Given the impressively wide range of spool sizes available, you’re likely to find a size that suits your needs. From merely sampling the material to buying it in bulk for high-volume printing, Centaur PP has you covered.

- Nozzle temperature: 220-240 °C

- Bed temperature: Up to 65 °C

- Diameters: 1.75 mm, 2.85 mm

- Price: ~$33 for a 500-g spool

- Colors: Black, white, natural

FormFutura Pegasus

FormFutura’s Pegasus PP Ultralight is, as its name suggests, extremely light, even for polypropylene. Enhanced with additives and nanotechnology, the material is 20% lighter than FormFutura’s other PP offering, Centaur. This makes Pegasus PP Ultralight ideal for parts that need to be extremely lightweight while maintaining durability and water resistance.

- Nozzle temperature: 215-245 °C

- Bed temperature: Up to 100 °C

- Diameters: 1.75 mm, 2.85 mm

- Price: ~$42 for a 500-g spool

- Color: Natural

Fillamentum

Fillamentum is a popular seller of high-quality retail filaments, and their polypropylene option – Fillamentum PP 2320 – is great. In terms of material properties, it’s decently flexible and thermally resistant (up to 100 °C).

Fillamentum’s comparison sheet, available on their website, shows that their PP filament is middle of the road in terms of ease of printing. It’s also worth noting that PP 2320 ranks pretty low in tensile strength and hardness, so it might not be best for producing super-strong parts.

- Nozzle temperature: 225-245 °C

- Bed temperature: 90-105 °C

- Diameter: 1.75 mm

- Price: ~$50 for a 600-g spool (~$42 per 500 g)

- Colors: Black, natural

Ultimaker

Ultimaker’s PP filament is an excellent choice for those looking to spend a little more on a high-performance material. Built into the Ultimaker ecosystem, Ultimaker users will benefit from automatic material detection and a well-integrated workflow. Unfortunately, this filament is only offered in a single diameter, size, and color, limiting applications.

- Nozzle temperature: 205-220 °C

- Bed temperature: 85-100 °C

- Diameter: 2.85 mm

- Price: ~$50 for a 500-g spool

- Color: Natural

BASF Ultrafuse

Formerly known as Innofil3D PP, BASF’s Ultrafuse PP is a high-quality choice for those who need consistent print quality and performance. BASF is known for producing materials for industry use, delivering consistent quality between batches.

The only slight downside is that the material doesn’t come in larger spool sizes for those doing a high volume of printing.

- Nozzle temperature: 220-240 °C

- Bed temperature: 60-80 °C

- Diameters: 1.75 mm, 2.85 mm

- Price: ~$60 for a 700-g spool (~$43 per 500 g)

- Color: Natural

Recreus

Recreus’ polypropylene filament is an easy-to-print option that requires a fairly low nozzle temperature. According to Recreus, this filament has many other useful properties, like chemical resistance, a smooth surface finish, and durability. Reviewers of this filament have also noted that this filament is easy to print but should be used with a strong bed adhesive.

This filament is available in both black and natural as well as in two diameters. Recreus suggests using their PP filament to print objects like mechanical parts, bottles, containers, or parts that won’t be subjected to high heat or friction.

- Nozzle temperature: 220-240 °C

- Bed temperature: 40 °C (bed adhesive recommended)

- Diameters: 1.75 mm, 2.85 mm

- Price: ~$60 for a 600-g spool (~$46 per 500 g)

- Colors: Black, natural

Owens Corning

For the most demanding applications, we recommend Owens Corning’s XStrand GF30-PP. Part of the company’s high-performance XStrand line, the filament is reinforced with 30% glass fibers for superior strength. In addition, users can benefit from the material’s integration into the Ultimaker Marketplace.

You can check the recommended settings for specific printers on Owens Corning’s website.

- Nozzle temperature: 240-275 °C

- Bed temperature: 40-120 °C

- Diameters: 1.75 mm, 2.85 mm

- Price: ~$90 for a 500-g spool

- Color: Black

3DXTech HyperLite

3DXTech is a manufacturer of professional quality additive manufacturing materials, and their HyperLite PP is a great polypropylene filament. According to the manufacturer, HyperLite is a special formulation of polypropylene material meant to reduce warping when 3D printed.

The filament is on the pricier end of the spectrum but is said to have many useful features that make it easier to 3D print. A heated enclosure isn’t required to achieve successful prints. Further, it’s possible to print very lightweight parts, thanks to Hyperlite’s low density (just 0.75 g/cc).

- Nozzle temperature: 210-240 °C

- Bed temperature: 60-90 °C

- Diameters: 1.75 mm, 2.85 mm

- Price: ~$60 for a 500-g spool

- Colors: Black, natural