Polycarbonate filaments are strong and amazingly heat resistant. Read on for the basics of printing with PC filament and the best brands!

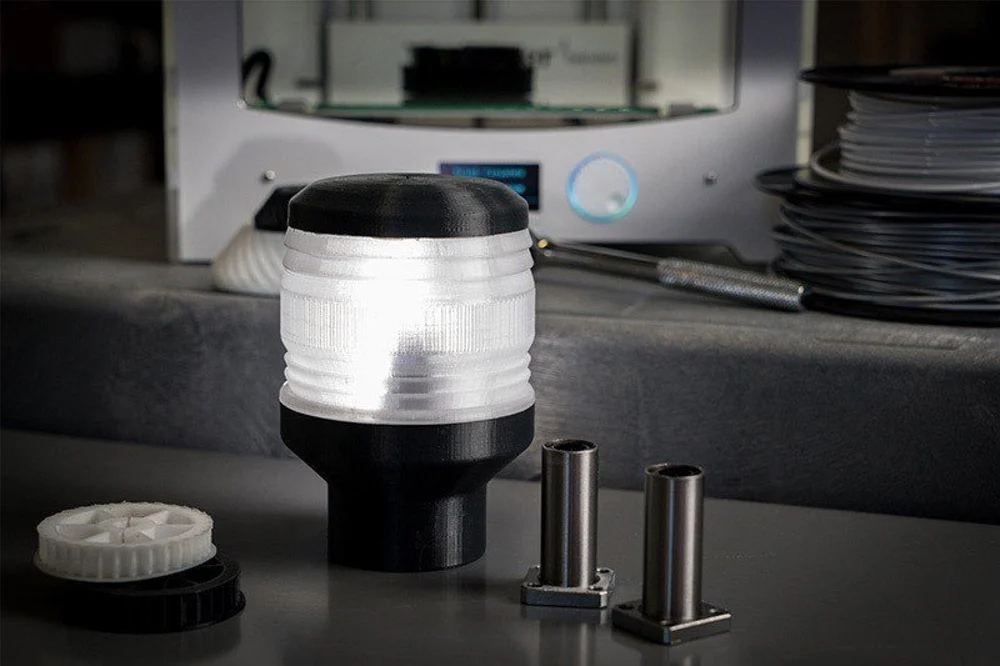

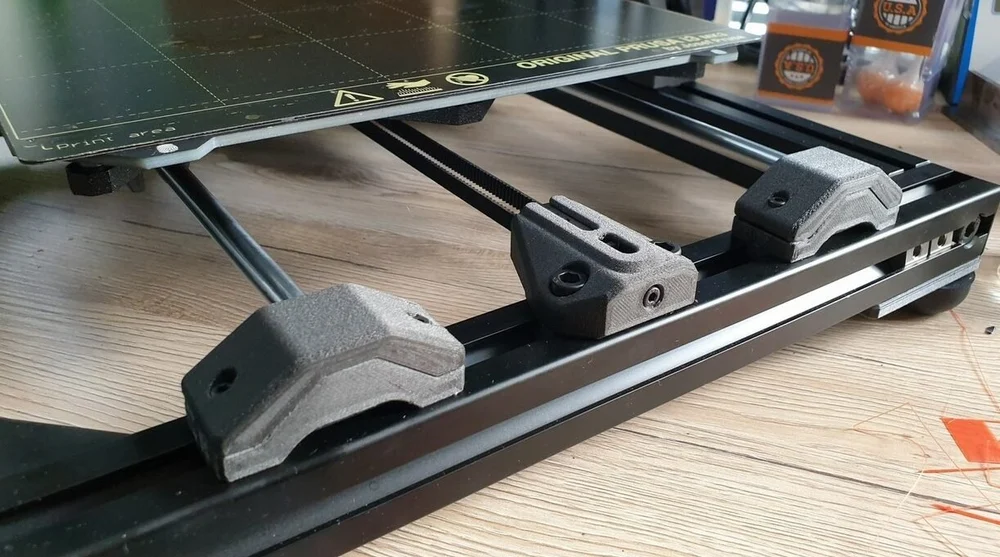

Polycarbonate (PC) is a powerful material used across many industries. It stands out for three main features: optical clarity, resistance to heat, and incredible toughness. This makes it perfect for use in electronic cases, automobile parts, robot bumpers, and similar parts that require durability.

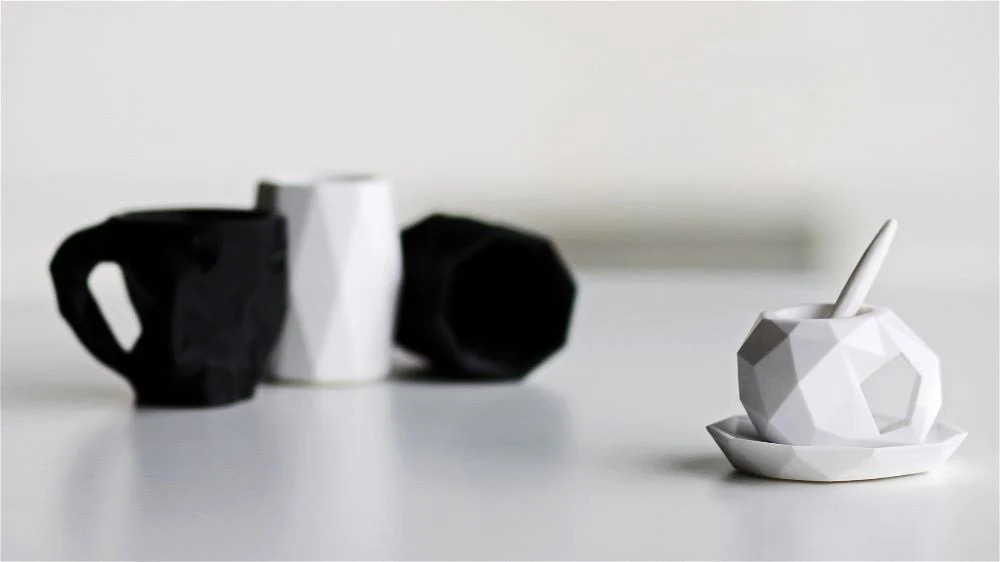

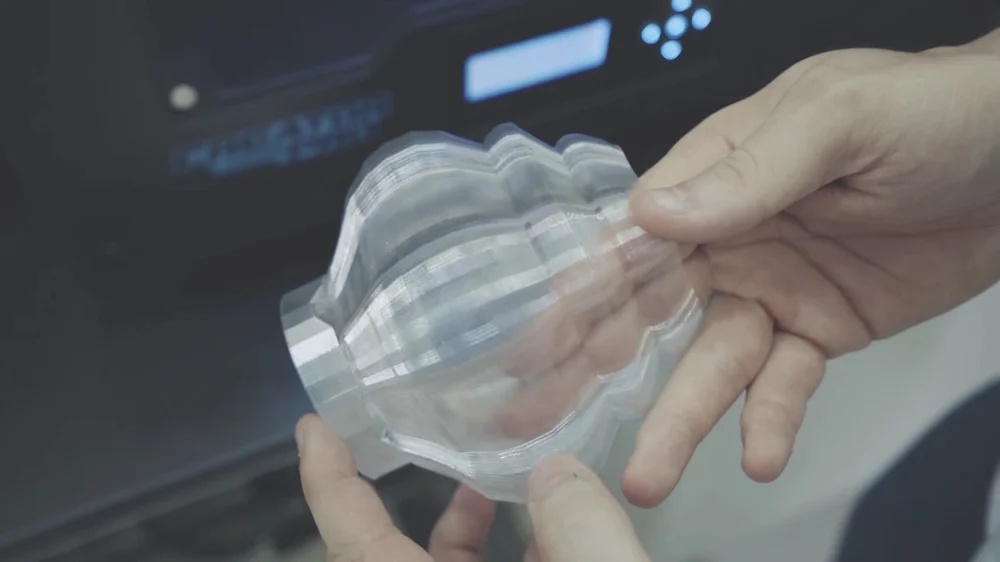

3D printing with variants of PC will typically get you a temperature resistance of just over 110 °C, yielding translucent, icy prints. Some brands offer a small range of different colors and blends, though variants are more limited than for more aesthetically oriented materials like PLA.

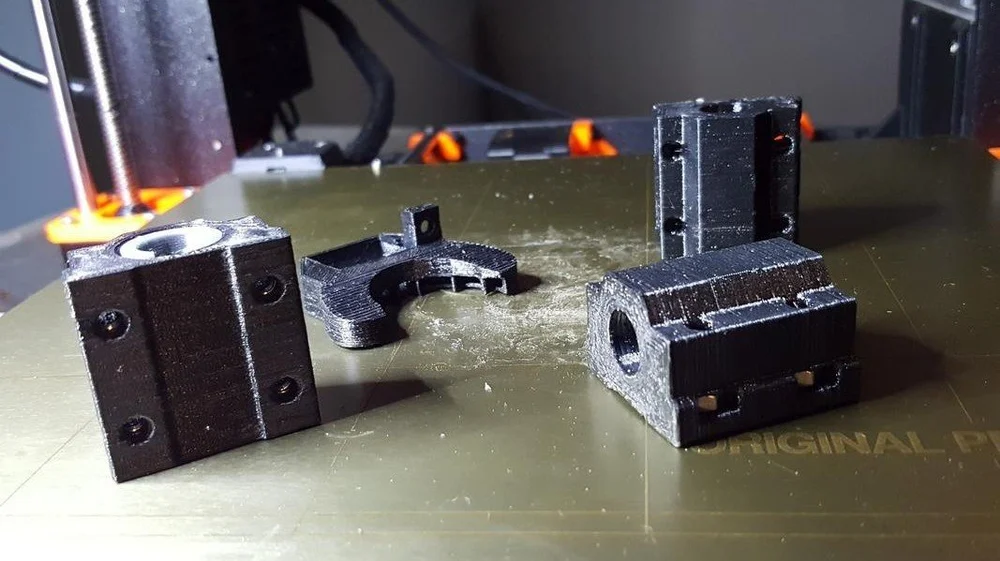

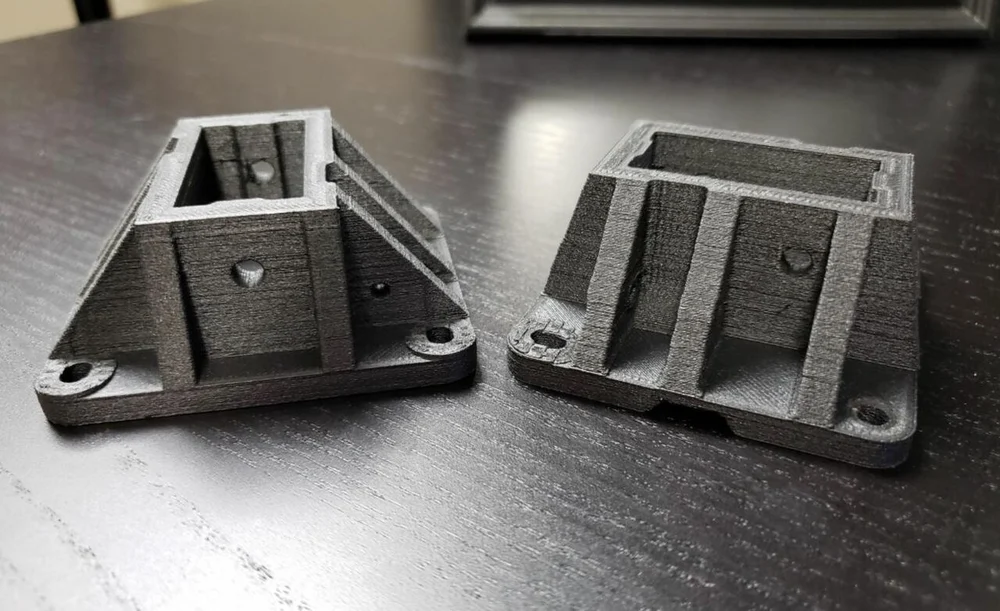

Parts printed with PC filament will come out fabulously strong, but printing PC can be quite a challenge. While some general settings are outlined below, as with any filament, check the manufacturer’s recommended settings before printing.

Suggested Settings & Considerations

- Nozzle temperature: 250-310 °C

- Bed temperature: 80-150 °C

- Fan speed: 0%

- Retraction distance: <10 mm

- Bed adhesion: Glue stick, hair spray, cyanoacrylate, Kapton tape, ABS slurry, commercial solutions

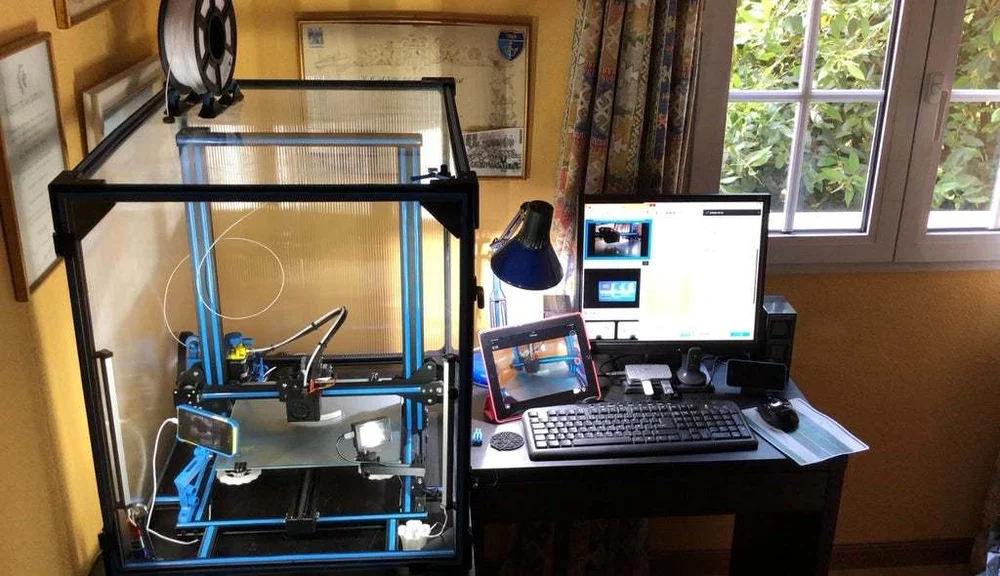

- Printer enclosure: Recommended (sometimes required)

- All-metal hot end: Required

- Warping: Severe

- Layer splitting: Severe

- Fumes and odors: Severe

With these settings in mind, we’ll also look at some troubleshooting tips and then dive into our round-up of the best brands offering PC filaments!

Troubleshooting

Unlike more common printing materials like PLA, polycarbonate is known to be a somewhat difficult material to work with due to its sensitivity to its environment. Below are a few of the reasons why PC filament is challenging to use, and some tips to better print with this material:

- High temperatures: Polycarbonate melts at much higher temperatures than most traditional printing materials. For this reason, an all-metal hot end and a heated bed are mandatory, and printing in a controlled environment with an enclosure is highly recommended. However, people have been able to successfully print PC without an enclosure, it’s just more difficult and requires more tuning.

- Air sensitive: Similar to ABS, PC filament prints poorly if there’s airflow, usually causing brittle prints. Part cooling should be turned off to ensure proper interlayer adhesion. Keep in mind that this material is designed to be functional (as opposed to aesthetically pleasing), which means that the print quality may suffer.

- Oozing: PC also has a strong tendency to ooze while printing. Tune your retraction settings, but avoid retraction distances of over 10 mm to prevent jamming. If your hot end doesn’t get hot enough, start printing at slower speeds. But a warning: the material generates strong fumes and odors. This is another reason why it’s usually best to print PC enclosed – or in a well-ventilated area.

- Hygroscopic: PC is extremely hygroscopic, which means it absorbs moisture from the air. This will quickly degrade the plastic, so keep your filament in a controlled, low-humidity environment. Airtight containers with desiccant packs will do the job. For long prints, consider printing straight from the container, feeding the filament out of a small, well-constrained hole.

- Drying: If your PC filament ends up absorbing moisture, printing performance will be seriously hampered. The material will likely weaken, pop while being printed, develop a poor surface finish, or string more easily. To remove the moisture, dry your filament using an oven, food dehydrator, or a commercial filament dryer, just like you would other filaments, like ABS or nylon.

Where Does That Leave Me?

PC is tough: both to print and to break. It will survive considerable stress and heat, but at the cost of warping, cracking, and a challenging printing experience. Manufacturers have improved PC’s printability in response to increased popularity, but don’t mistake it for the forgiving PLA. For most of us, there are plenty of other materials that print more easily and do a good enough job.

Sometimes, however, parts demand extreme dimensional stability, durability, heat resistance, and strength. If that’s what you need, grab a roll of PC and it won’t disappoint.

Below, we’ve gathered some of the best PC options around to get you started!

Polymaker PolyMax

Polymaker’s PolyMax PC (formerly known as PC-Max) is the toughest PC material the company offers. Tuned for smooth extrusion and warp-resistance, PolyMax PC delivers performance without compromising on printability (as far as PC goes, at least). Durability is exceptional, with drastically improved impact resistance as compared to other PC filaments. Its strength is also fit for the most demanding of applications, as demonstrated by Polymaker lifting over 800 kg with a PolyMax PC hook.

Available in white and black color variants, PolyMax PC stands out from the crowd for its toughness and printability.

- Nozzle temperature: 250-270 °C

- Bed temperature: 90-105 °C

- Bed surface: Magigoo PC, BuildTak

- Size: 750-g or 3-kg spools; 1.75 or 2.85 mm

- Colors: Black, white

Gizmo Dorks

Gizmo Dorks is a company that specializes in 3D printable filaments and bed adhesives. Gizmo Dorks’ PC filament is available in two visually appealing translucent colors, including blue and clear. This filament is also on the more affordable side, costing only around $30 per kilogram spool.

According to the manufacturer, this filament can be printed at speeds up to 80 mm/s, but the best results come from printing slowly and keeping the filament dry. Gizmo Dork’s PC filament is also fairly well-liked by the community. Numerous users have stated that they produced great prints when they dried the filament, used an enclosure, and dialed in their print settings.

- Nozzle temperature: 225-300 °C

- Bed temperature: 120-130 °C

- Bed surface: Glue stick, ABS slurry, tape, PEI sheet, Magigoo PC, Kapton tape

- Size: 1-kg spools; 1.75 mm

- Colors: Translucent blue, clear, black

3DXTech 3DXMax

PC’s heat resistance is already quite impressive, but what if you need more? Enter 3DXTech’s 3DXMax PC. This well-rounded PC filament features an eye-popping glass transition temperature of 147 °C for the most demanding applications. Just note that such a high heat resistance calls for equally high printing temperatures, making an enclosure highly recommended (although you can still print without one).

3DXTech also offers another version of this filament, known as 3DXStat, that’s safe from electrostatic discharge (ESD). This means that parts won’t pass on any discharged electricity, so it’s useful for prints that touch or interact with electronics, such as hard drive cases or motherboard covers. Besides ESD safety, 3DXStat is very similar to 3DXMax in price and printing temperatures.

- Nozzle temperature: 280-310 °C

- Bed temperature: 110-120 °C

- Bed surface: ABS slurry

- Size: 500-g spools; 1.75 or 2.85 mm

- Colors: Black, white, transparent (natural)

Fillamentum

Fillamentum is a popular manufacturer of a wide range of filaments, from PLA and PETG to vinyl and CPE. Fillamentum’s PC/ABS filament is a unique blend of ABS and PC, meaning it was made by mixing ABS and PC polymer pellets to form the filament’s mixture.

Blending the materials yields a product that proportionally captures the characteristics, good and bad, of both component materials. As such, you can expect Fillamentum’s PC/ABS filament to be slightly more difficult to print, but also more durable than pure ABS.

Other properties of this filament include thermal resistance up to 115 °C, high impact resistance, and ESD safety. According to Fillamentum’s comparison chart, this filament is very rigid and harder than their ASA, ABS, and HIPS filaments.

Fillamentum suggests that this blend is great for automobile applications and electronic casings. Unfortunately, this material is only available in a natural color and a 1.75-mm diameter, but a 2.85-mm option may be available in the future.

- Nozzle temperature: 260-280 °C

- Bed temperature: 90-105 °C

- Bed surface: Magigoo PC, 3D Lac

- Size: 1-kg spools; 1.75 mm (2.85 mm hasn’t been released yet)

- Colors: Natural

Polymaker PolyLite

PolyLite PC (formerly known as PC-Plus) is another PC offering from Polymaker. Compared to PolyMax PC, it’s stiffer and stronger, but not as durable due to its lower impact resistance. For what it loses in toughness, however, PolyLite PC makes up for with its relatively low price tag of ∼$30 per spool.

PolyLite PC only comes in a transparent variant, but unless your application specifically requires toughness, PolyLite PC is a well-rounded and inexpensive filament, making it perfect for those looking to try PC on a budget.

- Nozzle temperature: 250-270 °C

- Bed temperature: 90-105 °C

- Bed surface: Magigoo PC, BuildTak

- Size: 1- or 3-kg spools; 1.75 or 2.85 mm

- Color: Transparent

Raise3D

Raise3D is a developer of professional-grade 3D printers, like the Raise3D E2 and Pro2, and it also makes their own line of filament. Available in three colors, Raise3D’s Premium PC filament is a high-quality polycarbonate option that boasts high strength and impact resistance.

According to the manufacturer, this filament is also heat resistant up to 110 °C and flame retardant. Due to its industrial properties, Raise3D recommends using this PC material for industrial applications, end-use parts, and electronic cases.

- Nozzle temperature: 250-270 °C

- Bed temperature: 90-110 °C

- Bed surface: N/A (Raise3D recommends using a raft or brim)

- Size: 1-kg spools; 1.75 mm

- Colors: Black, white, transparent

Priline

Priline’s PC filament is another great option that offers a lot of strength at an affordable cost. Similar to 3DXTech CarbonX, Priline’s filament is a blend of PC and carbon fiber, meaning it was made from a mixture containing both PC and carbon fiber polymer grinds.

According to the manufacturer, this filament has an impressive diameter tolerance of just ± 0.03 mm and doesn’t warp or crack, meaning it should be easier to print. Customers have noted that this filament can yield great results, but tuning your slicer profile for this material is very important. Lastly, while it only comes in black, Priline offers both 1-kg and 2.5-kg spools, although the larger spool might be hard to track down.

- Nozzle temperature: 240-260 °C

- Bed temperature: 80-100 °C

- Bed surface: PEI sheet, glue stick, ABS slurry, hair spray, tape

- Size: 1- or 2.5-kg spools; 1.75 mm

- Color: Black

Ultimaker

Ultimaker is usually known for high-performance printers, but their filament is no less praiseworthy. With improved interlayer adhesion and well-tuned material profiles, Ultimaker PC is an exceptional, easy-to-print-with choice.

Being part of the Ultimaker ecosystem also brings additional benefits: Ultimaker 3, S3, and S5 users will benefit from the included NFC tag that encodes all of its print settings, streamlining operation. Additionally, for those with the S5 Pro Bundle, the built-in filament storage system keeps your PC fresh and dry at all times.

Available in 2.85 mm black, white, and transparent variants, Ultimaker PC should provide good printability and smooth integration.

- Nozzle temperature: 260-280 °C

- Bed temperature: ~110 °C

- Bed surface: Magigoo PC, glue stick, Ultimaker adhesion sheet

- Size: 750-g spools; 2.85 mm

- Colors: Black, white, transparent

3DXTech CarbonX

With CarbonX PC+CF, 3DXTech has achieved the same extreme heat resistance of the 3DXMAX, but now with carbon fiber. By incorporating carbon fiber, CarbonX takes PC’s already incredible mechanical properties and increases its stiffness, which is desirable in many applications.

This high-temperature, high-stiffness material is only available in black. Just note that carbon fiber is abrasive, so you’ll want a hardened nozzle to print with.

- Nozzle temperature: 280-310 °C

- Bed temperature: 110-120 °C (some users have had to go as high as 140 °C)

- Bed surface: PEI, Kapton tape, glue stick, ABS slurry

- Size: 750-g or 2-kg spools; 1.75 or 2.85 mm

- Color: Black

Additional Options

If you don’t think any of the above products are for you, next are a few additional options that are a little more professionally focused:

AIRWOLF

- Airwolf’s PC filament is on the higher end of PC options regarding price. However, according to the manufacturer, Airwolf PC filament is a high-quality material, and it’s great for printing automobile and electrical components. Unfortunately, you’re going to need a pretty powerful printer to use this material as it requires nozzle and bed temperatures of 300 °C and 140-145 °C, respectively.

LEXAN

- Lexan’s EXL filament is a PC material that’s heavily tested and proven to be a high-strength option. According to the manufacturer, the material is meant for more professional applications rather than consumer use, and it also offers lower temperature requirements.

ULTRAFUSE

- Ultrafuse’s PC/ABS filament is another blend of PC and ABS polymers, with similar temperature requirements to most PC materials. Like Lexan’s EXL filament, Ultrafuse’s PC/ABS filament has been tested for strength and has excellent layer-to-layer adhesion.

KIMYA

- Kimya’s PC-S filament is a PC filament that’s very heat resistant, according to the manufacturer. Kimya states that this material can be used to print physically demanding parts, such as automotive components, due to PC-S’ strength.

STRATASYS

- From one of the leading companies in the 3D printing industry, Stratasys’ PC filament is a great option for those looking to make robust prototypes and tooling equipment (e.g. jigs, manufacturing aids). Based on their tests, this filament is extremely strong, with a high tensile yield strength of 60 MPa, about 20% stronger than Stratays’ Nylon 12 filament.

INTAMSYS

- Lastly, Intamsys is a manufacturer of engineering-grade filaments, and their PC filament can be used to make a wide variety of durable parts, like medical device components and other fixtures. The manufacturer also points out that their PC filament is very resistant to temperature (up to 110 °C) and impact resistant.

Source: The Best Polycarbonate 3D Printers of 2022 | All3DP Pro