All-metal hot ends are incredibly popular and versatile, but they’re often prone to jamming. Read on to keep your hot ends running smoothly.

All-metal hot ends are incredibly popular for FDM 3D printers. By eliminating PTFE (Teflon) in heated areas of their assemblies, they’re capable of reaching much higher temperatures and have increased versatility compared to standard PTFE hot ends. Certain high-temperature materials common in 3D printing, such as polycarbonate, can only be printed with all-metal hot ends. For this reason, they’re both common as stock printer parts and also sold as an independent upgrade, such as the E3D V6 and the Mosquito hot end.

With this expanded temperature range, however, also comes a proclivity for jamming. It’s especially true when printing low-temperature materials like PLA, which happens to be one of the most frequently used materials in 3D printing. Needless to say, such malfunctions are less than desirable.

Fortunately, there are a number of ways to prevent these filament jams. We already have a dedicated guide for fixing general filament jams, but all-metal hot ends come with their own specific set of solutions.

Here, we’re going to give you five quick tips to keep your all-metal hot ends working like a dream. We’ll also indicate whether this jam is specific to all-metal hot ends or if it applies to other types of hot ends because in some cases, the metal material can exacerbate the situation.

Tip #1: Cool Your Heatsink Properly

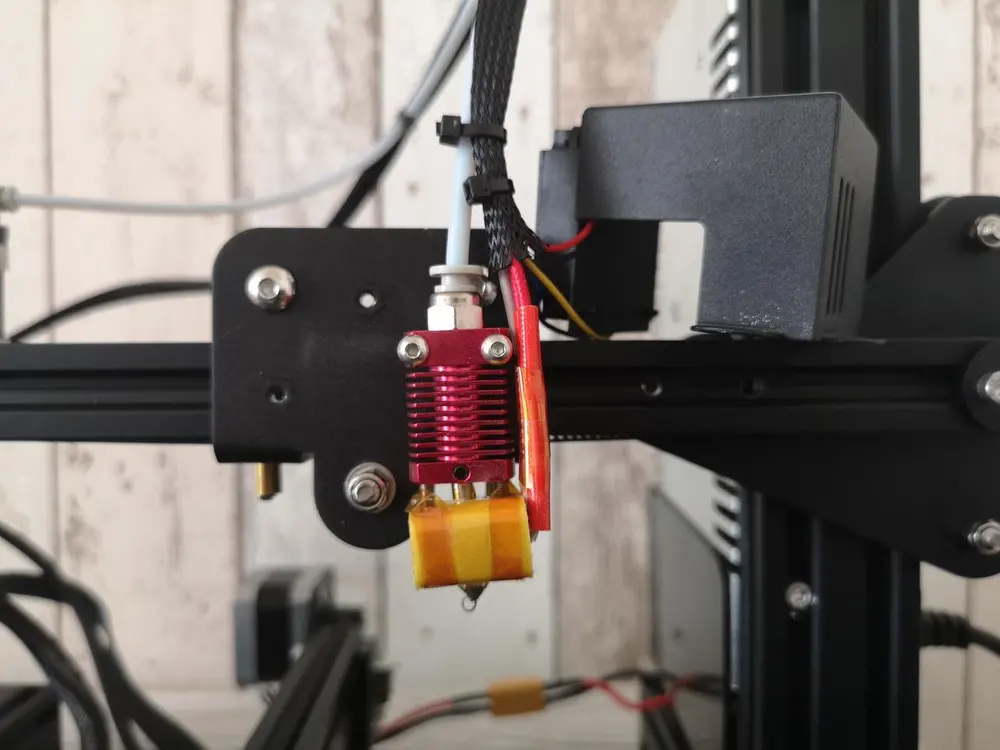

All-metal hot ends feature heatsinks that comprise the cold side of their assemblies. This provides a cold surface with which you can safely attach the hot end to your 3D printer.

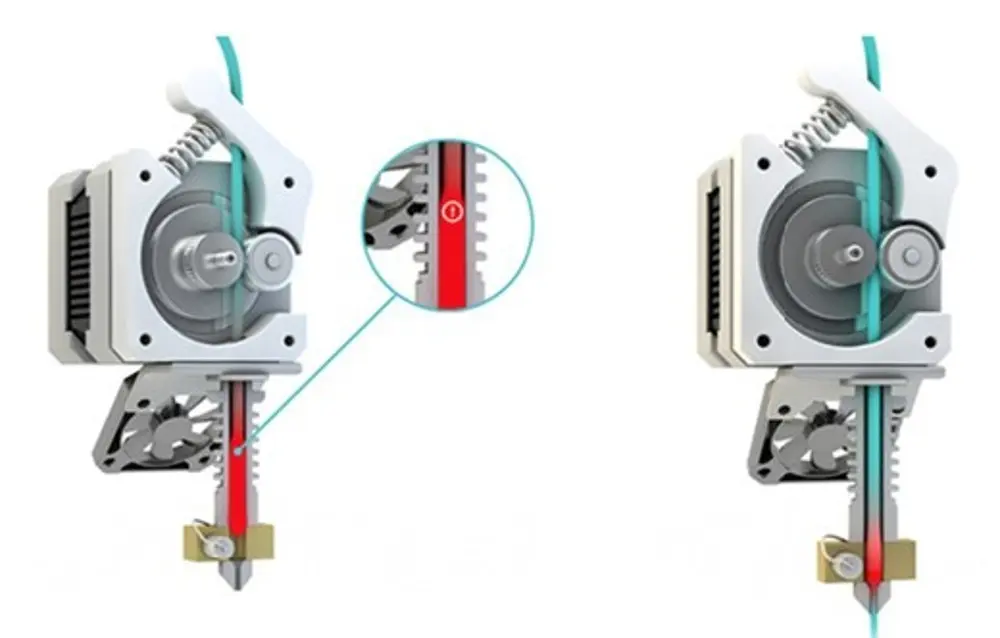

When a heatsink is improperly cooled, heat from the heated areas can travel up, in a phenomenon known as “heat creep” (pictured above). This causes filament in the heatsink to soften and become tacky. The filament then conforms and sticks to the walls of the heatsink, causing a jam.

Testing for this issue is very simple: Feel the heatsink and check if it’s distinctly warm. If it is, you’ll want to improve your heatsink’s cooling by getting a stronger heatsink cooling fan or a better fan duct to direct the air.

- Specific to all-metal hot ends? Yes

Tip #2: Reduce Retraction Distance

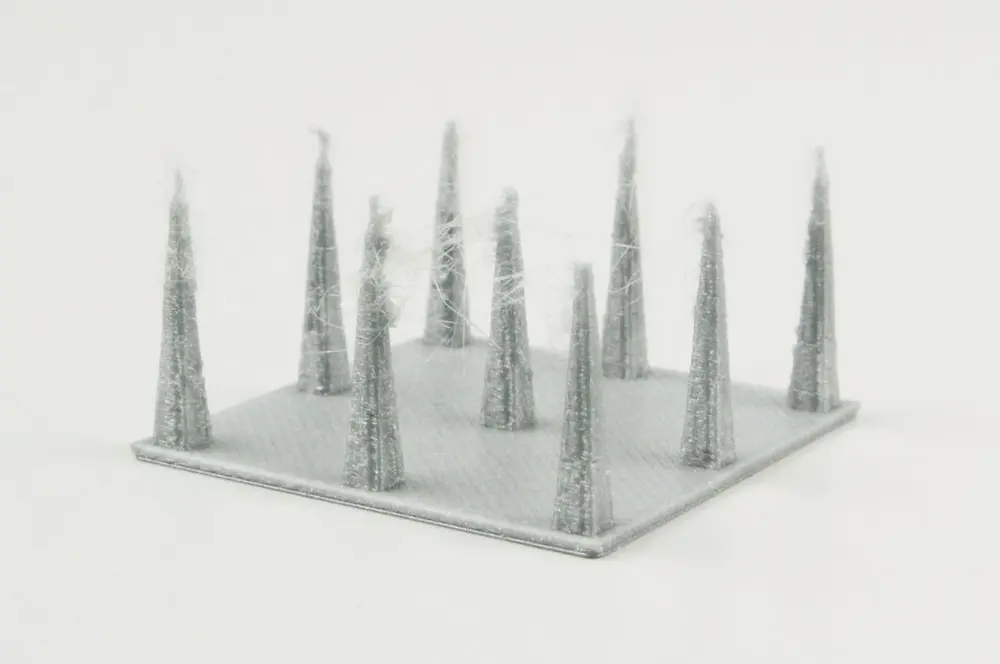

Retractions are commonly used during printing to reduce stringing and oozing. The process involves the extruder pulling the filament back up (retracting) into the hot end, which, depending on the type of filament used, can greatly improve print quality. Retracting is done in the slicer settings and can be set adjusted both for speed and length.

But, if you retract too far, softened portions of the filament may end up being pulled out of the heated area entirely. This causes a similar issue as improper heatsink cooling does, where the filament adheres to the walls of the heatsink.

To fix this, simply reduce your retraction distance. E3D recommends 0.5 to 2.0 mm for their products, which should serve as a good place to start. Printers with Bowden extruders may need longer retractions to reduce stringing.

- Specific to all-metal hot ends? Yes

Tip #3: Check for Misalignment

As mentioned before, all-metal hot ends are not lined with PTFE in heated areas. The PTFE usually does the job of smoothly guiding filament, so all-metal hot ends can suffer more from disrupted filament paths than their non-all-metal counterparts.

One cause of a disrupted filament path could be misaligned components in your hot end. Smooth passage of filament depends on straight and properly attached parts. This is especially true of the thin, fragile piece that connects the heater block and heatsink called the heat break. If anything is bent or out of place, the filament may catch and have a hard time getting through.

- Specific to all-metal hot ends? Exacerbated by all-metal hot ends

Tip #4: Check for Manufacturing Blemishes

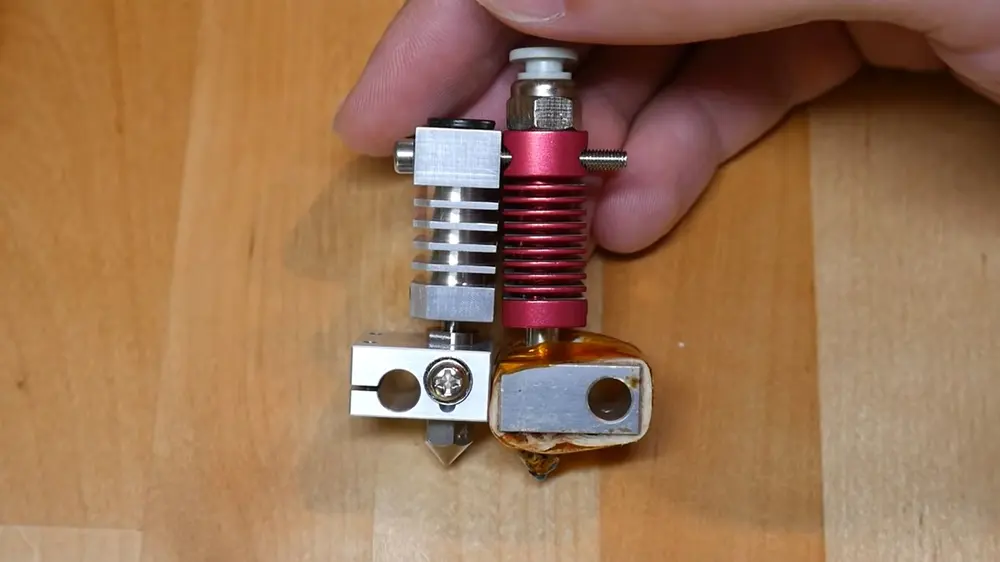

Manufacturing blemishes can be a serious issue, especially when your filament travels directly through metal parts in an all-metal design. If the interior of your hot end’s parts aren’t completely smooth, it can make material passage difficult. An example of a well-machined, smooth component compared to a poorly-machined one is pictured above. You’ll see that the poorly-machined hot end has irregular inside walls. The same machining issues can exist in the heat break and the heat sink, increasing the odds of partial jams.

Thankfully, to check for poor machining, you don’t have to cut your hot end open. Simply try sliding your filament through by hand, and if it catches at certain points (despite the hot end being well-assembled), your manufacturer may be at fault. Consider investing in some higher-quality components with tighter quality control.

- Specific to all-metal hot ends? Exacerbated by all-metal hot ends

Tip #5: Use Good Filament

This issue, like the previous one, stems from faulty manufacturing. In this case, we’re talking about filament. If your filament is inconsistent in diameter, it may have difficulty passing through the hot end. This is true even in PTFE-lined hot ends, but the higher friction from sliding over metal and the poorer compressiveness of metal is much less forgiving to your oversized filament.

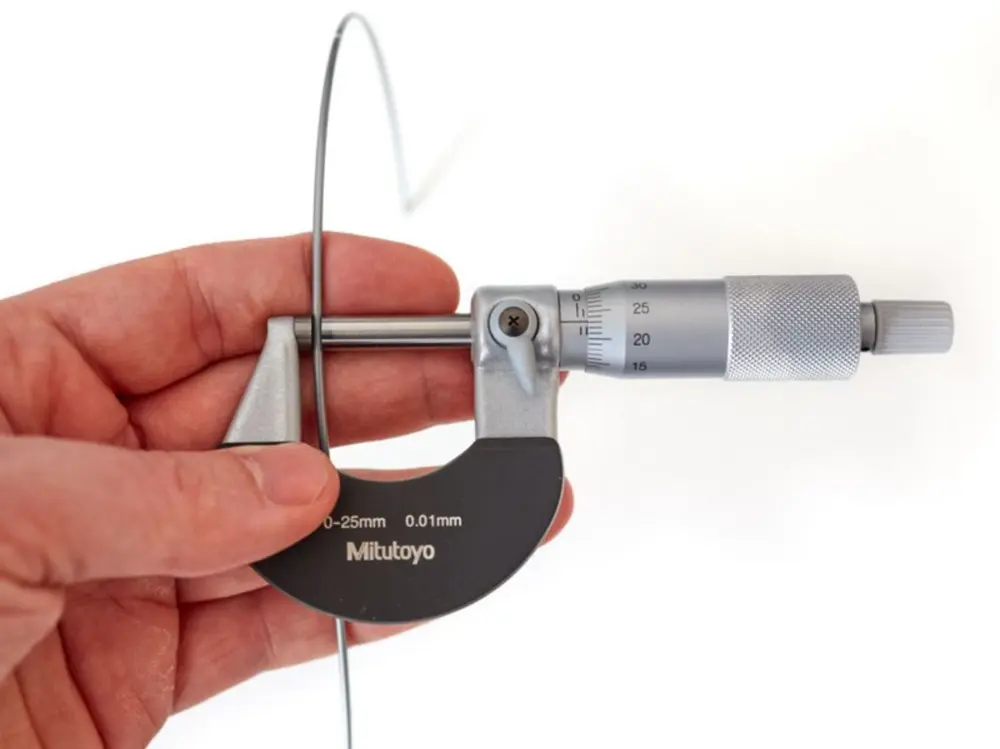

To check the uniformity of your filament, simply measure its diameter at random points along a reasonable length of material. This can be done with calipers or a micrometer. If its diameter appears to vary by more than 50 microns, consider switching spools or brands. For help on where to look for new spools, you can refer to our handy filament buyer’s guide.

- Specific to all-metal hot ends? Exacerbated by all-metal hot ends

And there you have it! Hopefully, these tips will save you a few headaches from any problems from your beloved all-metal hot end. For other 3D printing issues, you can refer to our comprehensive troubleshooting guide.