Pulling filament back into the hot end is a useful function but tricky to master. Read on to learn all about 3D printer retraction!

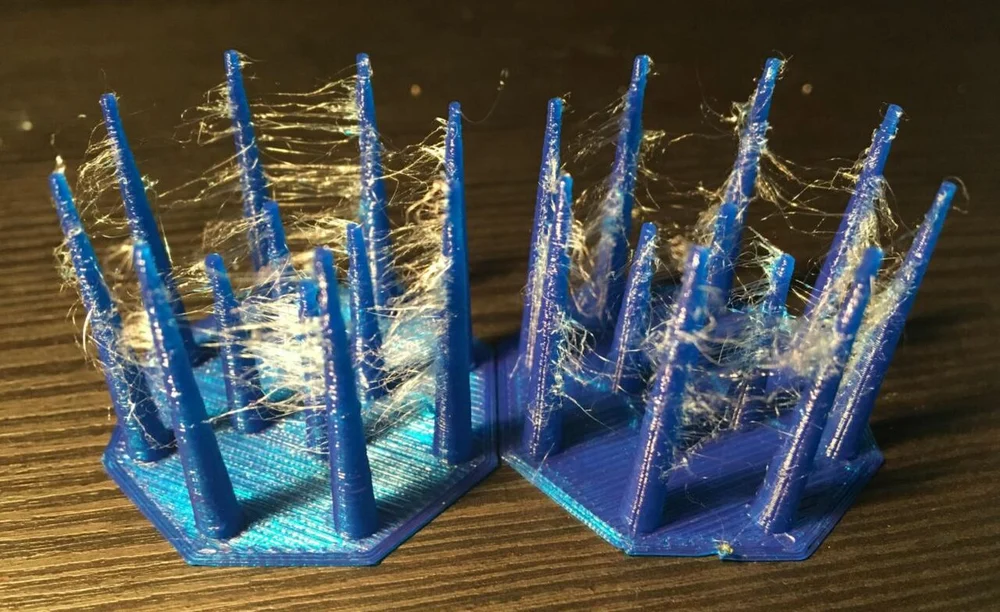

When your printhead moves from one point to another during printing, the heat of the nozzle combined with any pressure in the hot end results in some excess filament being forced out. This event is a form of over-extrusion and often leaves faint strings along the printhead’s path between points. These strings can be removed with tools and heat (e.g. hairdryer) after printing, but they’re still a bit annoying to deal with.

Retraction is a feature meant to eliminate stringing by pulling back (retracting) filament when the printhead moves to a new location. Just as filament is pushed forwards during the normal motions of a print, it’s sucked back during retraction. Doing so counteracts the hot end pressure and helps prevent excess material from flowing when it’s not supposed to.

Retraction can be enabled and tuned when preparing a model for printing in a slicer, like Cura or PrusaSlicer. When retraction settings are set correctly, they can eliminate stringing, blobs, zits, and other extrusion-related print quality problems.

Although the available retraction settings differ by slicer, many are the same or similar across programs. In this article, we’ll go over the most important retraction settings and how to adjust them.

Distance

Of the available retraction settings, perhaps the two most important are retraction distance and retraction speed.

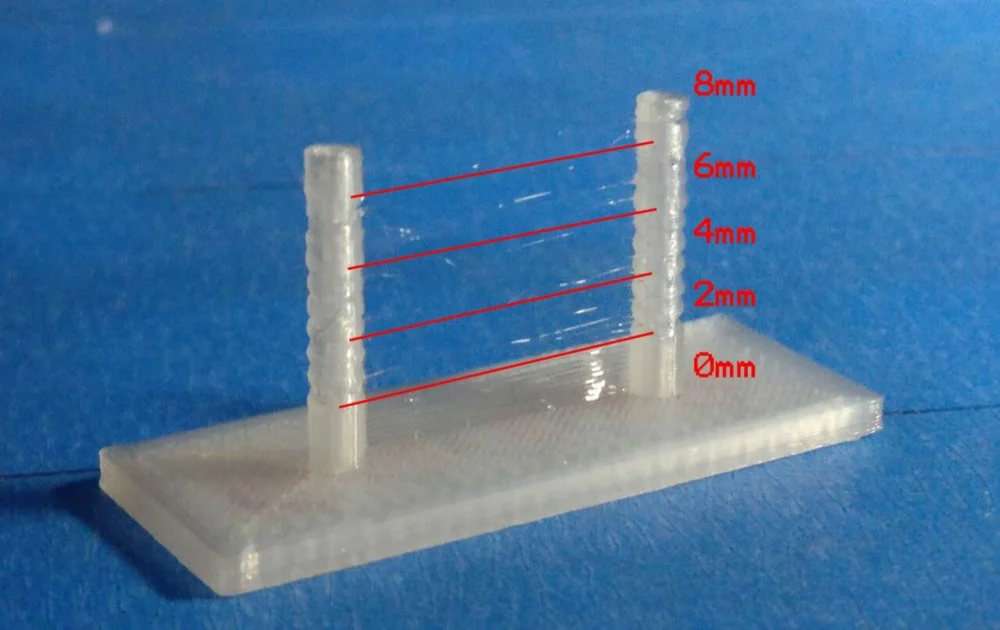

Looking first at the former, retraction distance is the length of filament that’s pulled back by the extruder every time retraction occurs. The longer this distance is, the more time a retraction might take depending on the speed, but also, the less likely you are to experience stringing.

Yet, if retraction were this simple, everyone would use the highest retraction value, but this is not a good idea. If you raise the value too much, the filament may retract too much and cause a hot end or nozzle clog.

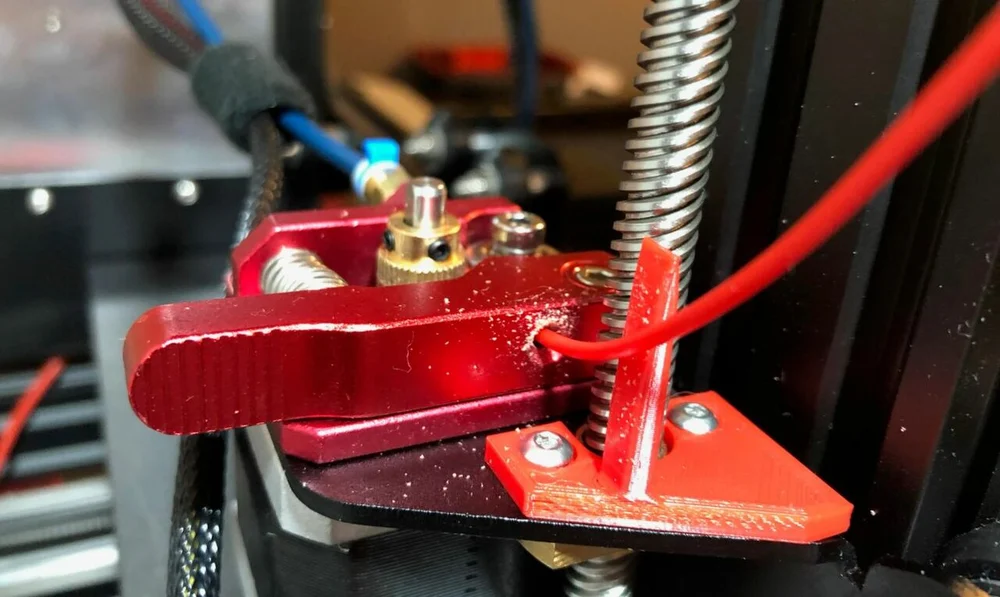

A typical retraction distance ranges from 2 to 7 mm, but this value depends on your extruder configuration (direct drive or Bowden), hot end, and other factors; there’s no one perfect value. If you want to adjust the retraction distance, try tweaking the default in 1-mm increments until stringing is eliminated without any clogs or other problems.

Speed

Retraction speed is the other important retraction setting, and as you might have guessed, it determines how quickly retraction is carried out. This setting is very important because it can influence print time as well as how effective retraction is at eliminating stringing.

For example, if your retraction settings effectively eliminate stringing with a distance of 5 mm and a speed of 40 mm/s, you may experience worse results with the same distance and a speed of 20 mm/s. That’s because a slow speed won’t relieve the pressure fast enough to prevent excess material from exiting the nozzle. On the other side of the spectrum, too high a speed could cause a number of problems, including breaking the filament inside the hot end, and you may still experience stringing.

Ideally, you want to use the fastest functional speed to reduce stringing and print time. For reference, your slicer’s default retraction speed will likely lie between 30 and 60 mm/s. If this value isn’t working for your printer, try adjusting the speed in 5-mm/s increments.

Minimum Travel

If two retraction movements occur close to each other, the filament is pulled back, extruded, pulled back, and extruded again, all in a short amount of time. This constant reversal of the filament motion increases the chance of a nozzle clog significantly, and that’s where the minimal travel distance setting comes in.

The minimum travel distance is the last important retraction setting we’ll go over, and it controls how frequently retraction occurs in a specific area. This is achieved by requiring the nozzle to move a certain distance before it’s allowed to perform retraction again.

While a larger minimum distance increases the likelihood of stringing by preventing retractions from transpiring, it reduces the chances of a nozzle clog. This setting is especially useful if you’re printing a model with many close-by separate locations where retractions could occur, like a hairbrush. The minimum travel distance is usually 1-2 mm, but you should adjust this value by 1-mm increments if you have issues.