Looking for a filament to use in your engineering projects? MatterHackers’ NylonX may be for you. Follow along as we test a spool out!

What’s Special

MatterHackers, the well-known American company based in Southern California, sells a vast variety of high-quality filaments, printers, tools, and parts to makers around the globe.

Their NylonX filament is an “engineering-grade” material with a dimensional accuracy of ±0.02 mm. A blend of high-quality nylon and “micro-carbon fibers”, this filament is marketed as having high tensile strength, good stiffness, and good impact resistance.

A half-kilo spool of NylonX will cost you $58.00 (with free shipping within the USA). It’s available in both 1.75 and 3.0 mm diameters, and you can have it in any color you want, as long as it’s black.

If you’re looking to have something tough printed but don’t have any use for your own material, you can always try a 3D printing service. Through Craftcloud, All3DP’s 3D printing price comparison service, you’ll find the best provider for your needs, at no extra cost!

Verdict

After a bit of a bumpy start, we were able to get some fairly decent prints in NylonX, but it definitely needs some tuning.

For the most part, the prints have a very smooth finish, however we also encountered a lot of stringing. Warping also became an issue, as we had one test fail after coming free of the print bed. However, after we got past these issues, the material proved to be very sturdy and generally prints well.

The NylonX came well-packaged in a plastic vacuum-sealed bag with a desiccant pouch. We received ours along with the other filaments we reviewed from MatterHackers and were happy to find that the filaments do not have individual boxes, resulting in less overall waste. Unfortunately, the bag wasn’t resealable, so the filament must be kept in a dry box for storage in humid climates.

MatterHackers notes that it is very important to dry your NylonX before use, regardless of climate and storage conditions. Due to its highly hygroscopic nature, improper drying is the source of the majority of printing issues with Nylon materials.

How to Dry Filament: PLA, ABS, & Nylon

We tested our spool using an Original Prusa i3 MK3S in stock configuration. The finish on the prints is matte and somewhat sparkly, and feels very similar to balsa wood in both weight and texture.

Test #1: 3DBenchy

Our first test was the ubiquitous 3DBenchy. After one failed attempt, we managed to get a completed model.

The first thing to note is that bed adhesion is slightly tricky. Our print bed is PEI, so we needed a layer of glue stick in order for the NylonX to stick properly. Our first failure happened when the Benchy warped off the bed and then delaminated completely.

On our second try, we applied more glue stick and isolated our printer from drafts, which seems to have solved the issue. Aside from this, there was only a slight issue with stringing, and on the smokestack, we saw a bit of blobbing due to the complete lack of print cooling.

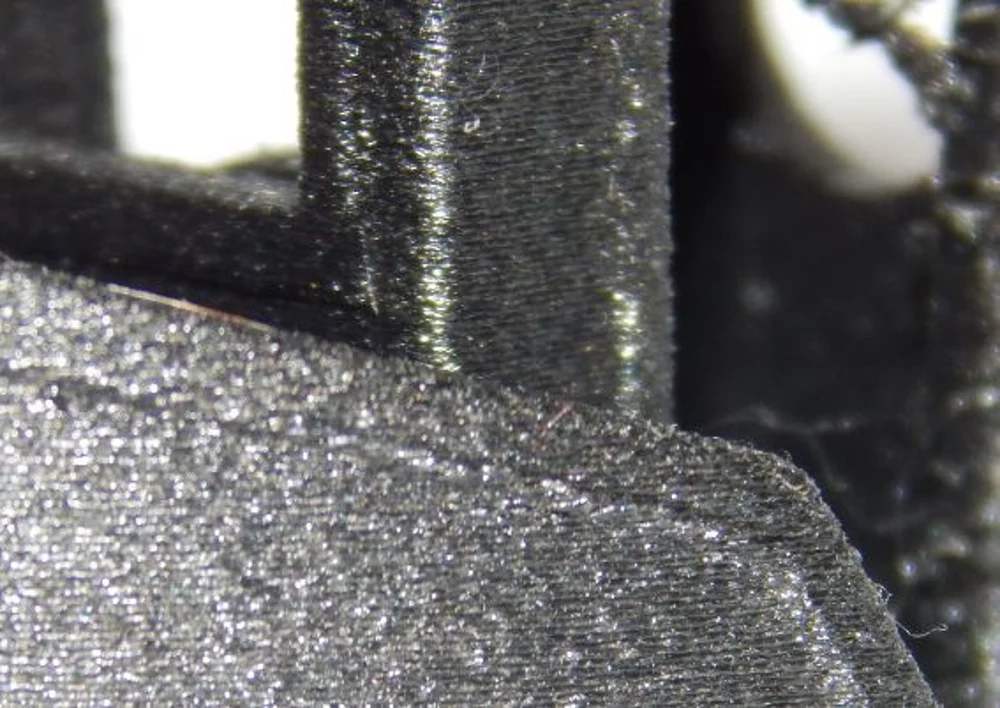

Other than that, the 3DBenchy turned out really well, with even layering (as seen in our close-up) and clean details.

Test #2: Gear Holder

Our second test, inspired by the industrial nature of the filament, was the Gear Holder for Paper Clips by Maksim Timofeyeff.

Here we were able to get a successful print on our first try, with much less issues. Overall, we had a fair bit of stringing between the gear teeth, but the finish was very smooth and crisp.

There were no other issues with this print.

Test #3: Hood Scoop

Our third and final test, inspired by the frequent use of carbon fiber in sports cars, was the Hood Scoop Hot Rod by Ozkal Ozsoy.

This is admittedly a very difficult print, which we attempted without supports. The NylonX performed fairly well, with only a few areas in which the bridging failed and then recovered. The overall stringing in this print was actually fairly minimal, and for the most part the print came out cleanly.

The small surface area on the print bed did result in some slight warping, but thankfully this did not cause a failure or any other issues.

Final Thoughts

Aside from the issues with stringing and warping, we think this filament has a lot of potential. Our difficulties mostly originated from the base material, nylon, but the stringing could also be due to the fibers inside. With a little bit of tuning in the slicer, there could be a huge improvement in quality.

If you’re willing to do a bit of post-processing to remove stinging, NylonX is certainly a very good option for durable end-use parts for a variety of users.

Specs & Settings

We tested our NylonX on an Original Prusa i3 MK3S in stock configuration with PrusaSlicer.

Based on Nylon’s similarity to ABS, we used the “0.15 mm Quality MK3” and “Generic ABS” profiles, with the following changes:

- Extruder temperature: 257 °C

- Bed temperature: 65 °C

We used PVA glue stick on our print bed for adhesion, as recommended by MatterHackers.

The manufacturer’s recommended settings are as follows:

- Extruder temperature: 250-265 °C

- Bed temperature (with PVA Glue): 60-65 °C

- Filament diameter: 1.75 mm or 3.0 mm (±0.02 mm)

How We Review

For those curious about how we got to our conclusion, we review filaments using the following guidelines:

Each and every spool is brand-new and unopened.

Our first print is always a 3DBenchy. We use this to check for any inconsistencies in quality, color, and finish. After that, we print a few other models, the results of which we present to you. We slice the model using the latest version of PrusaSlicer. We do not post-process the prints in any manner; we simply remove them from the bed and cut off any support materials.

We start with the manufacturer’s recommended settings (where available). When the manufacturer offers a range of values, we go for the arithmetic mean. Therefore, if we are given a printing temperature range of 200–220 ºC, we would print at 210 ºC (unless noted otherwise).

For this review, we used an Original Prusa i3 MK3S in stock configuration. Statements regarding print quality are based on the printer’s ability and reputation to successfully print a wide variety of other filaments and models.

We would like to mention that every spool of filament can be slightly different, and filaments often vary greatly even within a small range. Simply fiddling with a single setting like retraction can have huge effects on print quality. This can make the difference between a disastrous fail and a wondrous success.

So, if you own a spool of this filament, we invite you to contribute in the comments below! Did you manage to get your prints to turn out? Did you have an interesting or strange experience? Let us know – we’d love to hear from you!

(Lead image source: Emmett Grames / All3DP)

Source: https://all3dp.com/2/matterhackers-nylonx-filament-review/