3D printed orthotics is in the next stage of an often slow discipline. See how it’s reducing costs and speeding up customization worldwide.

Past Meets Future

Orthotic devices, commonly referred to as simply “orthotics”, are wearables used for support and rehabilitation of injured body parts. They can be used for a wide range of debilitating conditions, from simple limb immobilization to full-body instability.

In order for these devices to be effective, they often need to be custom-designed. And that’s one of their major drawbacks: They can be extremely time-consuming to manufacture. Traditionally-made orthotics often require frequent fitting sessions, which can lead to several months of waiting before the user equips the final piece.

3D Printing Increasing Accessibility

Thanks to its affordability and ease of use, 3D printing has simplified the entire fitting and customization process. 3D scanning and modeling significantly reduces the amount of time required to produce and deliver orthotics to patients.

In the following, we’ll take a look at some of the most promising existing and developing 3D printed orthotics projects.

If you already have a custom orthotic designed and ready but don’t have access to suitable 3D printing equipment, consider using a 3D printing service. Through Craftcloud by All3DP, you’ll have access to a wide range of materials and finishes. You’re also guaranteed to benefit from professional production and expertise.

Now, let’s get to those revolutionary 3D prints!

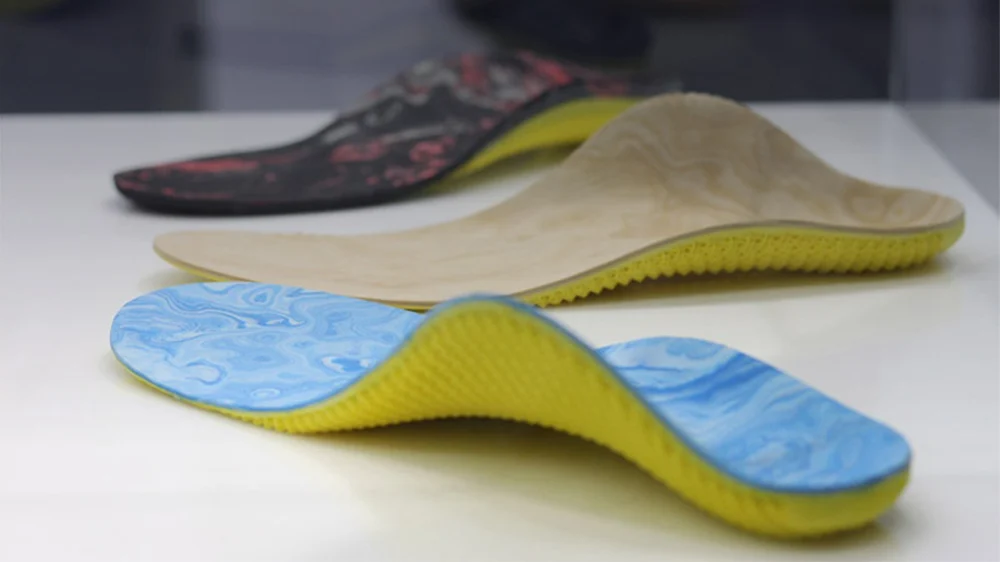

Insoles

Perhaps the most well-known type of orthotic device is the shoe insole, which is mostly used to non-surgically correct foot and ankle problems. Patients (and people who care about their feet) benefit greatly from customization since these orthotics can be matched to the specific issues they have, and they match each individual foot perfectly.

RS Print

RSscan is a company that’s been involved in the development of insoles for some time. Now, thanks to their innovations and partnership with the 3D printing service company Materialise, they’re producing personalized insoles on a large scale using selective laser sintering (SLS).

The joint venture, RS Print, started in April 2014 and has been so successful that athletes have worn and even won triathlons with the help of its 3D printed insoles.

HP FitStation

HP first announced its foray into the 3D printed orthotic industry in 2017 with the creation of FitStation. The platform 3D scans the consumer’s feet, measures foot pressure and analyzes gait. With the resulting data, HP is able to create a fully-customized insole, which is printed using its Multi Jet Fusion (MJF) technology.

Braces and Supports for Disabled Children

Orthotic devices are designed for people of all ages and walks of life. The goal of this next company is to produce solutions for disabled children, including body braces and leg supports.

Andiamo

This is a particularly moving story that began in 2003 with Diamo Parvez, who suffered from cerebral palsy. As with most patients with this disease, he required orthotic braces to support his body.

Unfortunately, the production of such devices usually requires uncomfortable procedures like plaster casting. In some cases, this can take at least six months to perfect.

For growing children, it also requires frequent refittings, which meant regular trips to the hospital for Diamo. Unfortunately, he passed away because of complications from the condition when he was just nine years old in 2012.

Because of their experience, Diamo’s parents, Naveed and Samiya Pervez, established Andiamo in 2014, following a successful crowdfunding campaign. They utilize 3D scanning and printing to deliver orthotics within two weeks of receiving orders. The service is live in the UK and parts of Europe.

Knee Brace

The knee is one of the most complex joints in the human body. It’s responsible for holding one’s body weight and endures high pressures during walking and running. This next amazing innovation came about to enhance the performance of the user’s knee.

BioNeek

The BioNeek knee brace uses a damper to absorb shock and reduce impact, protecting the knee while improving stability and mobility. An adjustable hinge prevents the joint from hyperextension, relieving pain for chronic patients and facilitating rehabilitation. Each user has a custom-sized BioNeek brace with foam padding inside for improved comfort.

The bionic exoskeleton brace is manufactured by Intamsys with a special engineering polymer: PEEK, which is a great material for withstanding high temperatures and chemicals. It’s also very strong, which makes it ideal for mechanical projects.

Chinese company Sichuan Ju An Hui is responsible for the design. They developed the advanced medical device to assist people and relieve symptoms associated with knee disabilities.

Remolding Helmet

A lot of newborns experience a deformation or flatness of the skull caused by laying on one side for prolonged periods of time. The technical name for this condition is plagiocephaly.

Perhaps the most effective way to correct plagiocephaly is via orthotic treatment. By wearing a custom-fitted helmet, the child’s head is gently corrected as it grows during a relatively short period of time.

Conventionally, these devices are made using a costly and time-consuming process that involves polymer foam milling. But this next European firm has developed an innovative solution.

Talee

Talee is a cranial remolding orthotic device from Invent Medical, and it works likes this: First, the baby’s head is 3D scanned and a digital model is customized to address the patient’s specific needs. Then, the helmet is manufactured via HP’s MJF technology, and that’s it!

Unfortunately, it may be a while before this is globally available. According to their website, the Talee is not yet an FDA-cleared product and isn’t currently available in the US.

Limb Immobilization Device

Custom-made orthotic devices for immobilizing limbs can replace itchy, uncomfortable, and sometimes smelly plaster casts that are commonly used for post-traumatic and therapeutic recovery. The only downside is that you can’t get all your buddies to sign their names on it.

Xkim

Spanish company Xkelet was founded in response to frustration with the traditional bone-healing process. Specifically, Jordi Tura, one of the founders, broke his leg and quickly became fed up with the discomfort of a cast.

When worn, the company’s device, Xkim, doesn’t scratch or irritate the skin. The lightweight design also eliminates the need for removal before showering or during doctor’s visits.

Alongside the orthotic, Xkelet has developed an iPad scanning app for doctors. After mapping a patient’s limb, the app facilities orthotic customization to ensure a perfect fit. The final design is then sent directly to a 3D printing service, which produces and delivers the immobilization device.

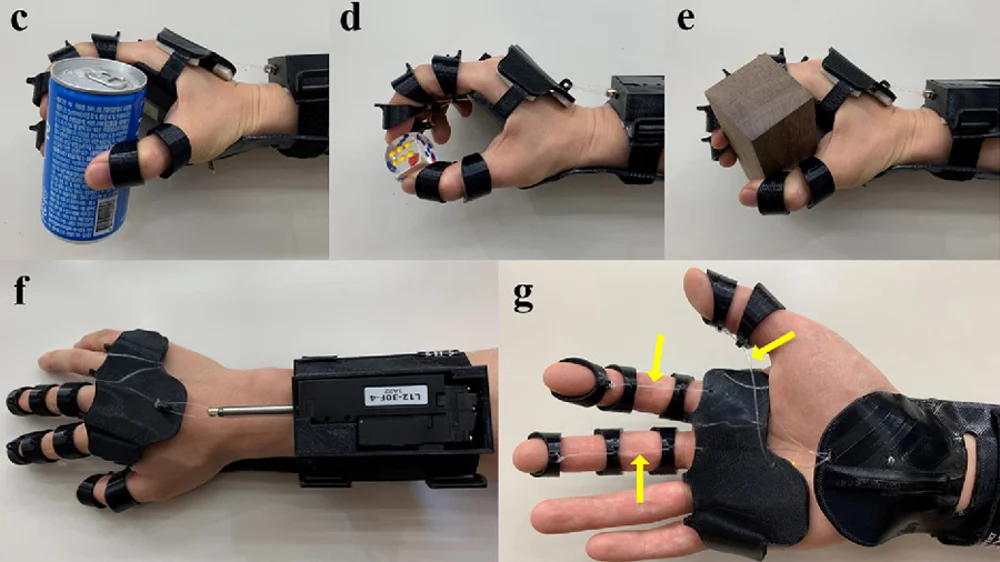

Myoelectric Hand Orthotis

Spinal cord injury is a major condition that causes temporary or permanent dysfunction in the body’s sensory and motor systems. The injury may include the complete loss of muscle function, which results in physical and emotional disabilities with patients and their families.

While stem cell research focuses on healing spinal cord injuries, new wearable devices are constantly being developed to assist patients in achieving motor function.

GIST’s Myoelectric Device

To aid patients with SCI, in 2019, South Korean researchers from the Gwangju Institute of Science and Technology (GIST) developed a hand orthotic device controlled through electromyography (EMG).

This futuristic device is an exoskeleton system designed for patients who have lost or reduced muscle function. Its main purpose is to provide independence and give users basic motor functions, like picking objects up and holding them, even if they entirely lack the wrist movements.

The team turned to 3D printing due to its low-cost and personalization potential, while the electronics are mainly open-source Arduino boards.

The initial tests have shown positive results, as patients found the device to be intuitive and easy to use. Hopefully, this innovation will lead them to handle common life tasks more easily in the future.

Ankle-Foot Orthosis

This is another orthotic device designed with children in mind. In particular, it’s for kids who have difficulties walking and standing.

Animake

When he was 3 years old, Nik Vlašič was diagnosed with cerebral palsy. Even at the age of 7, he was unable to stand or walk without help. The turning point came for him with custom-made ankle-foot orthoses (AFOs) and physical therapy, which allowed him to walk independently.

In order to help his son, Nik’s father, Matej, used a Formlabs Form 2 printer to create several AFO prototypes that would fit inside the child’s shoes. It took half a year to perfect the prototypes, and the custom-made orthotics were a perfect, blister-free fit.

This was a breakthrough: Normal AFOs cost around $5,000, while Matej’s cost around $15.

Influenced by Nik’s progress, professional studies were conducted to evaluate the device’s performance. They verified the AFO’s positive impacts, which lead Nik’s parents to team up with his physiotherapist Dejan Tašner to provide diagnostic treatment and further develop AFOs. Under the company Animake, the team aims to help other children in need of custom AFOs, which can prevent, eliminate, or ease various disorders.

(Lead image source: Hello Xkelet via YouTube)