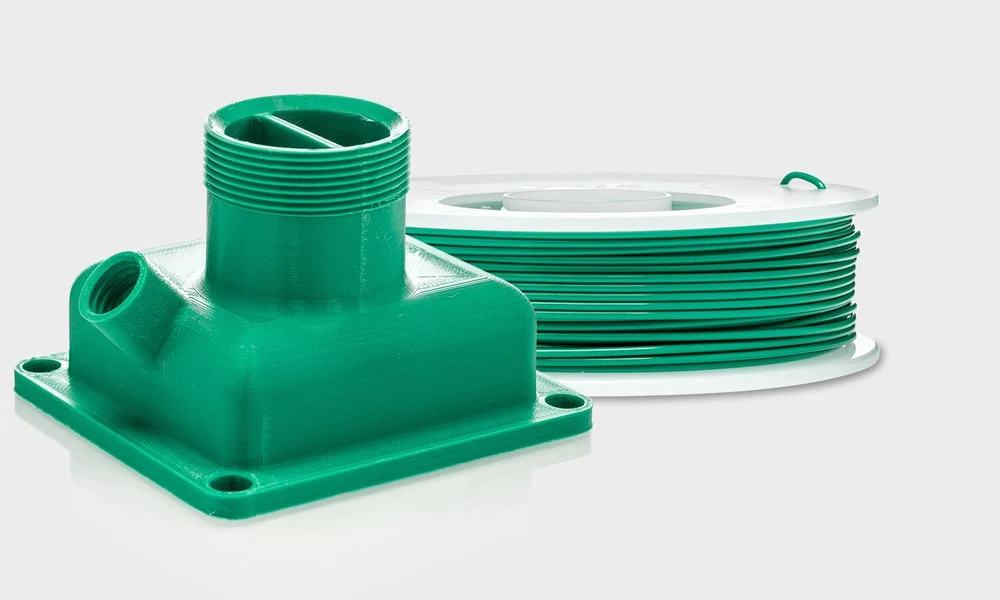

PETG is one of the most popular filaments for FDM printing. Read on to find out how it’s made and how to use it!

PET Improved

PETG was adapted from PET, a material that was created in 1941 to use as synthetic fiber in the textile industry. In the early 1950s, PET began to be used for food packaging and, since the mid-70s, as a material for bottles. PET is still used for all of these, especially plastic bottles, and it’s the most used plastic in the world.

However, PET has disadvantages. It tends to crystalize at high temperatures, which makes it opaque and weakens its structure. It becomes frail and bubbly, making it unsuitable for 3D printing. PETG was developed to overcome these disadvantages.

PETG has a similar composition, but the difference is in how it’s chemically achieved. According to TWI Global, PET is created through esterification from glycol and terephthalic acid, resulting in a long chain of polyethylene terephthalate. In contrast, PETG is achieved by replacing the ethylene glycol with cyclohexane dimethanol, which is a larger monomer. It helps to avoid the tight-knit molecules of PET, reducing crystallization.

This new composition makes PETG suitable for 3D printing. In the following sections, we’ll provide an overview of its material and printing properties. We’ll also introduce you to some popular PETG filament brands.

Material Properties

PETG is a thermoplastic polyester, meaning it can be deformed with heat, as opposed to a thermoset plastic, which can’t be deformed and just burns.

Among its positive attributes, PETG has significant chemical and heat resistance, good durability, and formability (compared to other plastics). It also has a bit of flexibility, making it suitable for applications that require impact resistance. As we mentioned above, PETG is food-safe and non-toxic.

On the negative side, PETG has a softer surface than PET, so it’s more prone to wear. That being said, it remains more durable and heat resistant than PLA.

If not treated correctly, PETG can be harmful to the environment. While some suggest PETG is recyclable, many recycling programs exclude it. Fortunately, some manufacturers have produced recycled PETG from post-industrial waste.

Printing Properties

PETG has similar printing settings to ABS, but it’s easier to handle. For example, PETG is mostly odorless, and printing with an enclosure isn’t necessary. Like ABS, it requires high heat. The recommended temperature of the nozzle is usually between 220 °C and 260 °C. PETG also needs a heated bed, with temperatures ranging from 60 °C to 80 °C.

In terms of adhesion, PETG adheres too well to some build surface materials (PEI, for example). Prints or the build surface can be damaged when you try to remove the print. It’s best to cover the surface with glue or hairspray in preparation for printing.

Parts printed in PETG will have a glossy and smooth surface finish and will be semi-rigid, but a little smoothing can also do wonders.

Just keep in mind that PETG is highly hygroscopic. If it’s kept in humid places, it can become brittle, both in the spool and printed parts. For some tips on how to keep your PETG filament dry, check out 3D Printer Filament Storage: 12 Ways to Store Filament

Variations

Even though PETG is the most popular PET variant, there are others. rPET and PETT, for example, have some advantages over PETG.

- rPET is short for “recycled PET”. It can be created from any PET materials, whether from previous prints, plastic bottles, or other applications of PET. It remains waterproof and food-safe. Brands like Reflow and FormFutura produce filaments made from recycled PETG.

- PETT, also known as polyethylene cotrimethylene terephthalate, is a bit more rigid and has a more glossy and transparent finish than traditional PETG. The main manufacturer for PETT is Taulman, who sells it under the name “T-Glase“.

Products

As PETG has gained popularity, many brands have jumped on the bandwagon. The following are a few of the most notable options.

MatterHackers

MatterHackers offers two popular PETG options: Pro PETG and Build Series PETG. Their Pro PETG is made for professionals, and it’s extra tough. Their Build Series PETG has a bit less dimensional accuracy than the pro version, but it’s still extremely trustworthy. Further, at about $20 per kg, it’s the less expensive of the two of them.

Ultimaker

Ultimaker recently released a PETG filament that’s available through a few popular retailers, including MatterHackers and Dynamism. Ultimaker also manufacturers copolyester filaments, CPE and CPE+, that are similar to PETG but not exactly the same. It’s important to make this distinction, as many retailers place copolyesters under the PETG category, whereas the manufacturers are more likely to make a distinction between the materials.

ColorFabb

ColorFabb sells a couple of different PETG as well as copolyester filaments. One of the options, PETG Economy, is marketed as a high-quality PETG at an affordable price. It’s available in several colors and spool sizes. You may see ColorFabb’s HT and XT filaments sold as PETG on some retailers’ websites, but as we mentioned above, the manufacturer differentiates those from their PETG options.