The right print temperature for PETG can be elusive. Read on to learn all you need to know about PETG bed and print temperature settings.

In recent years, countless new filaments have been introduced, each with a unique set of properties. One of them, PETG, has gained a lot of popularity, and rightfully so. It’s stronger and more durable than ABS, yet it prints as easily as PLA.

PETG is incredibly alluring because it’s compatible with almost any FDM printer, has many good qualities, and is reasonably priced. However, since it’s relatively new, many people don’t yet know how to correctly print with it.

Although we can provide some typical ranges, unfortunately there’s no perfect universal print temperature for PETG. Each brand of filament is slightly different. But don’t worry, we’re here to help! In this article, we’ll be going over and giving you everything you need to determine the perfect temperature for your particular brand of PETG.

Finding the Perfect Temperature

Although there’s a general range of temperatures that work best for PETG, you must determine the precise temperature for your particular spool of filament.

The easiest way to find the best temperature is through trial and error. Conduct many test prints and compare results. Each print should be done at a low speed, to ensure that the only factor affecting printing is temperature.

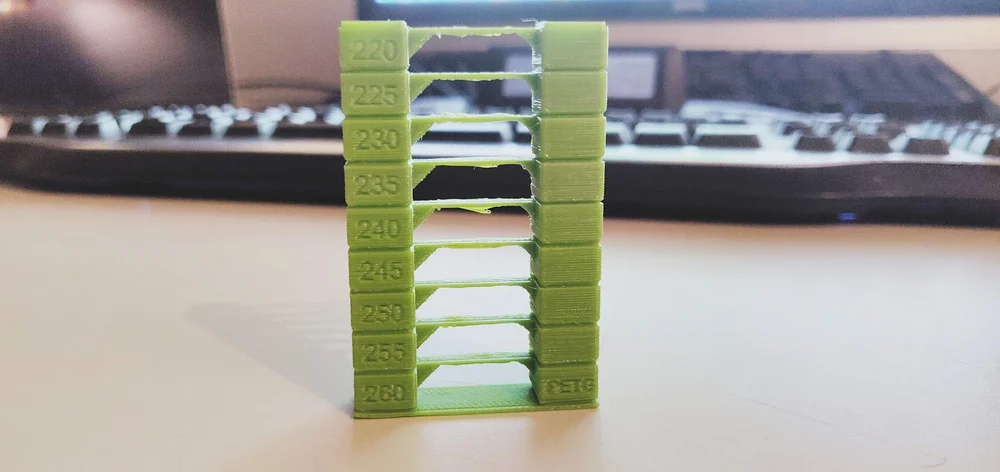

Start at the bottom of the given range, and print tests at five-degree intervals. Look out for the common effects of temperature being too high or low (provided in the following). Once you have explored printing throughout the entire range, compare your prints and determine which temperature produced the best results with your filament.

If you don’t mind playing around with G-code, an even faster method to determine the ideal temperature is to use a temperature tower. If all goes well, you’ll only need to run a single test.

Hot End Temperature

Similar to ABS, PETG requires much hotter temperatures than PLA. In general, the hot end should be heated to between 220 and 250 °C.

If the layers of the print don’t adhere, your temperature is too low. This is a common problem, so ensure that the hot end temperature is high enough.

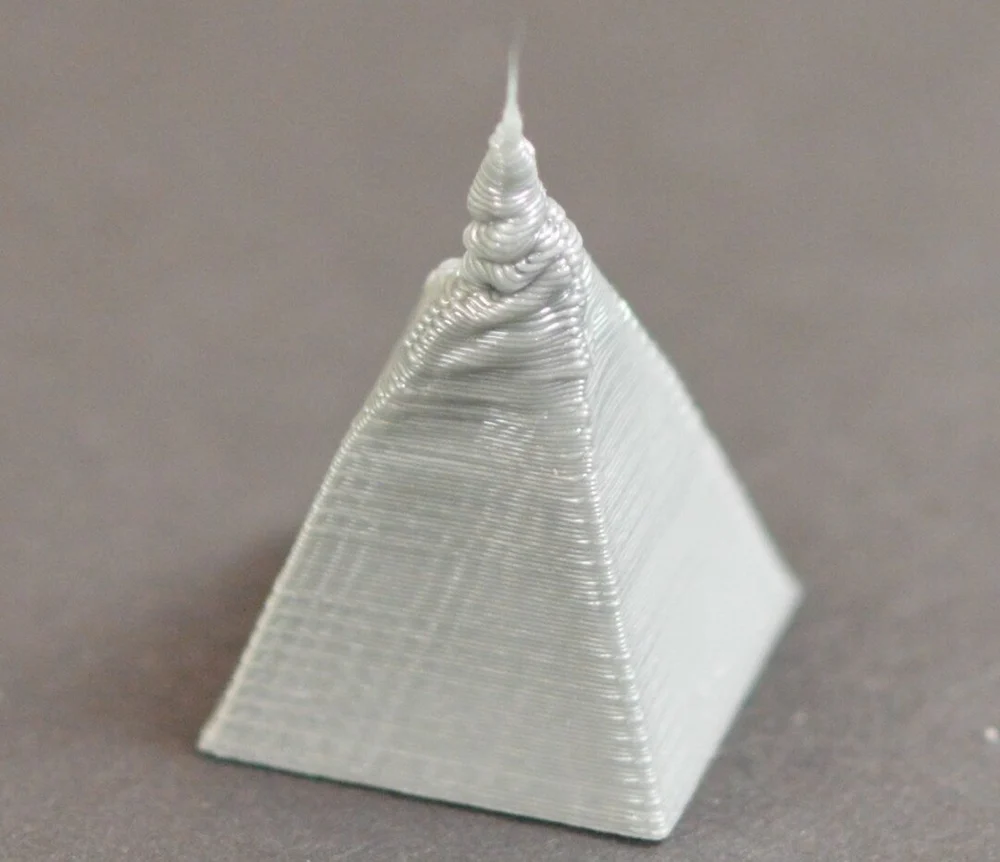

Though fairly rare with PETG, if the print comes out droopy and messy, the temperature is too hot.

Despite this, PETG will normally print without defects within the given range.

Build Platform Temperature

Unlike ABS, PETG doesn’t require a heated bed, as it doesn’t undergo nearly as much warping.

However, it’s very helpful to still heat your print bed. If you do, set it to temperatures similar to what PLA uses: 50 to 75 °C will help ensure that the extruded filament sticks. Some makers even claim to print at temperatures as high as 100 °C!

As with hot end temperatures, incorrect temperatures for the bed may result in certain defects. If the bed is too hot, it’s very common to experience a phenomenon known as elephant’s foot.

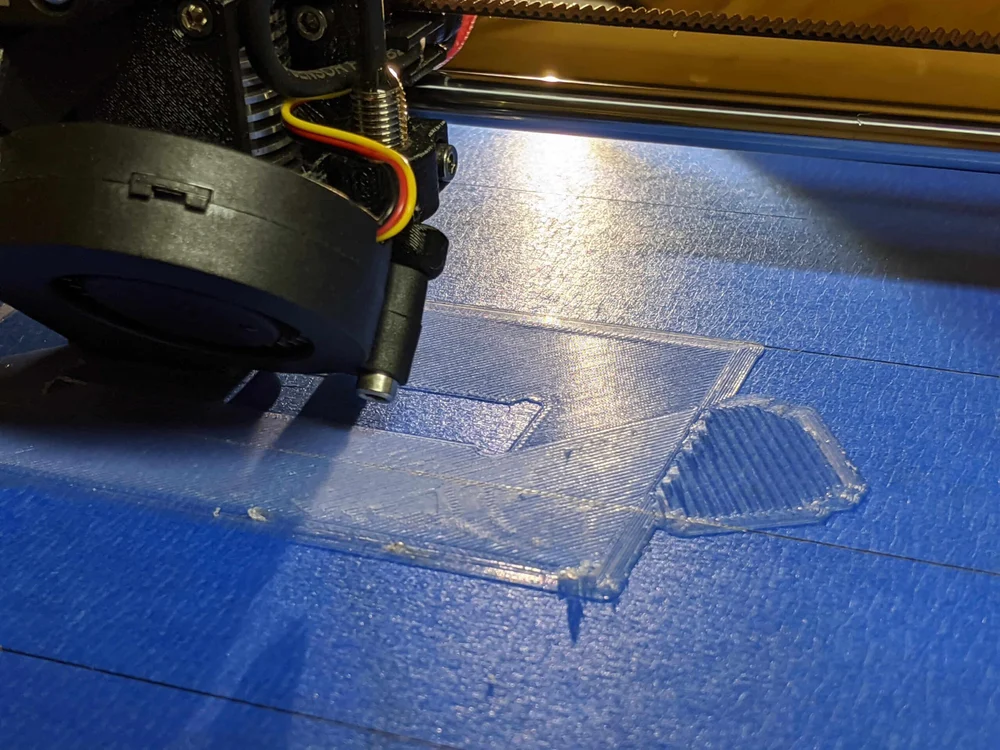

Alternatively, if the filament isn’t properly sticking to the bed, it may be too cold. Naturally, this can also happen if you’re printing without a heated bed. The best way to solve this problem would be to apply some sort of adhesive to the surface, such as a glue stick or blue painter’s tape.

Additional Printing Tips

In addition to temperature, there are a few other factors that can help you achieve great PETG prints.

- Use blue painter’s tape: If there are any problems with first layer adhesion, simply put down a layer on top of the build plate.

- Turn on your fans: Since PETG experiences minimal warping, it’s best to have cooling fans on. This will increase the overall quality of prints and improve overhangs. That said, it’s recommended to set them to somewhere between 20% and 50%.

- Keep your filament dry: Like many filaments, PETG is hygroscopic, meaning that it will readily absorb moisture from the air. This can negatively impact print quality, so it’s important to store your filament in a dry area. If necessary, you might even want to dry it before printing.

- Get your retraction settings right: PETG is notorious for stringing. Playing around with retraction settings will be most helpful in solving this issue, but lowering the print temperature can also help.

Overall, PETG is generally very easy to print with, as it requires no enclosure nor heated bed, making it compatible with virtually all FDM printers. It combines ease of printing with great strength and durability, making it a great filament choice for any print.