Prototyping a product can be costly and slow, but using 3D prototyping, or rapid prototyping, you can iterate efficiently. Explore this method in the following guide.

What Is It?

Rapid prototyping, also known as 3D prototyping, is not only limited to 3D printing. It actually refers to a process of iterating through a design by quickly manufacturing physical prototypes and making small changes at each step to improve it.

Traditional prototyping techniques like injection molding require weeks or even months to manufacture each iteration. And that’s not to mention the extra expense compared to other methods like 3D printing or laser cutting.

Thanks to digital fabrication technologies, we’re now able to do rapid prototyping relatively quickly using a variety of materials with differing properties, such as cheap PLA, impact-resistant ABS, durable nylon, and more.

But rapid prototyping can be carried out using multiple distinct technologies, each with different use cases. In this article, we cover which technologies are available for rapid prototyping and what can be achieved with them.

3D Printing

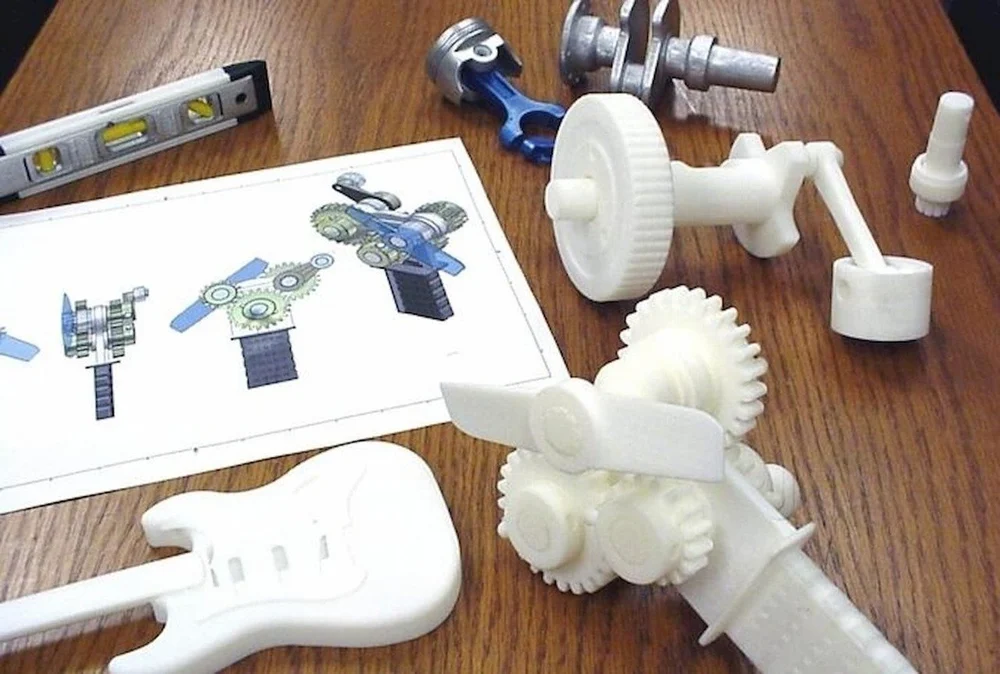

Rapid prototyping is one of the most common applications for 3D printing, which offers a great deal of flexibility in terms of speed and material selection. 3D printing allows the manufacturing of low-to-medium performance objects at a low cost, but it’s not suitable for mass production.

3D printing is considered an additive manufacturing method, meaning material is added until a specific shape is formed. Depending on the level of accuracy required, there are different kinds of 3D printing processes available:

- Fused deposition modeling (FDM): The most popular and affordable 3D printers available, they use thermoplastic filament, which is melted and extruded layer by layer. It’s recommended to use them for first-run prototypes or for home use.

- Stereolithography (SLA): SLA 3D printers have a tank filled with liquid resin into which a platform slowly sinks and then rises while a UV light hardens each layer. The process repeats until the 3D model is complete. It’s not as cheap as FDM printing, but it’s recommended for high-resolution prototypes.

- Selective laser sintering (SLS): These 3D printers use powder, which is sintered layer by layer with the help of a laser until you get a solid model. It’s a more specialized 3D printing method, and that’s why it’s recommended for high-end industrial prototypes. Unsurprisingly, it’s much more expensive than FDM or SLA.

3D printing can be very useful for prototyping in jewelry design, architecture, or engineering to make mechanical parts, cases, architectural models, props, and functional consumer products.

Laser Cutting and Engraving

Laser cutters are great tools for prototyping, making use of subtractive manufacturing. They allow you to cut pieces with different thicknesses relatively fast in a very accurate way using a laser beam. This technology is able to cut many different materials, such as acrylic, wood, or even metal sheets.

After laser cutting, you can use laser engraving to add details like text or logos to complete a prototype.

Some laser cutting companies offer prototyping services with the capacity to cut harder materials like stainless steel, carbon steel, or aluminum. Given its wide range of capabilities and advanced material selection, this process is frequently used in the military, automotive, and aerospace industries, among others.

CNC Milling

CNC milling is another subtractive process that can easily achieve good results when used in rapid prototyping. A CNC mill is basically a precise cutting tool that has barely any limitations in terms of materials that you can cut with it. You’ll be able to cut soft materials like foam or harder ones like glass, wood, plastics, or even metals.

You can produce 2D or 3D digital models in the software of your choice and export it into a CNC-compatible format and once your raw material is clamped to the work table, the mill will do the rest. A massive array of different bits allows you to get all kinds of cuts on all kinds of materials.

In the prototyping process, some parts made with CNC milling can be made in one single piece using the cutting tools but the interesting part comes when the prototype has multiple parts with a particular purpose. In this case, a milling head can be replaced with a polishing, slotting, or grinding tool, making this technology more versatile compared to others.

CNC milling is especially used in industries like automotive, aviation, and aerospace. It’s also used to make industrial or medical equipment.

Final Thoughts

Rapid prototyping is clearly not limited to one tool or technology. Modern fabrication techniques provide a solution for almost any use case in almost any industry, it’s just a matter of picking the right process for your application.

Source: https://all3dp.com/2/what-is-3d-prototyping-simply-explained/