What is 3D printing? What’s 3D printing good for? How does 3D printing work? We simply explain this exciting technology in depth.

What is 3D Printing Used For?

3D printing enables people like you and me to easily manufacture complex objects from the comfort of our own homes.

Unlike the behemoth machines installed in factories, modern desktop 3D printers are small (they’re “desktop” for a reason), cheap (you can get the cheapest ones for $100; less than the cost of a smartphone), and easy enough to install to operate.

Lots of people have already installed a 3D printer in their homes. So what are they doing with it? A lot, it turns out. Your kid wants a new toy? 3D print it! Your door handle has broken? 3D print a new one. Custom design teacup? Why not!

It is often cheaper, faster and more customizable to 3D print something in your home than to buy such sundy items from the store. The technology is already quite mature and the build quality of the fabricated items is constantly improving. It’s not hard to imagine the oft-cited vision of a world where everyone has a 3D printer in their homes. That may never happen, but it is an utterly achievable thing for your home, should you choose.

How does 3D Printing Work?

If you are familiar with the operation of a normal Inkjet printer (the one that prints documents), then it’s pretty easy to understand a 3D printer.

For example, let’s say you want to make something useful, like a case for your iPhone. If you had a 3D printer, this is what you would do in order to make it.

1. Just like a document printer requires a digital document (a PDF or DOC file) for printing, 3D printers require digital design files of 3D objects (STL files are the most common). So you would first need to create or download a digital file that encodes the design of the iPhone cover.

2. Once you have the digital design saved, your computer will process the file and get ready for printing. You can change settings just like you change settings in a normal Inkjet printer.

3. Next, you choose a material for the iPhone cover (preferably plastic) and load your 3D printer with enough material. In a normal Inkjet printer, you buy and use ink cartridges. In a 3D printer, you buy and use filaments made of different materials. Filaments serve as the “ink” for 3D printers.

What Can I Create with a 3D Printer?

It’s hard to imagine what you might do if you had a device that could make things. So to get your imagination going, here are some examples of how people might use their 3D printers.

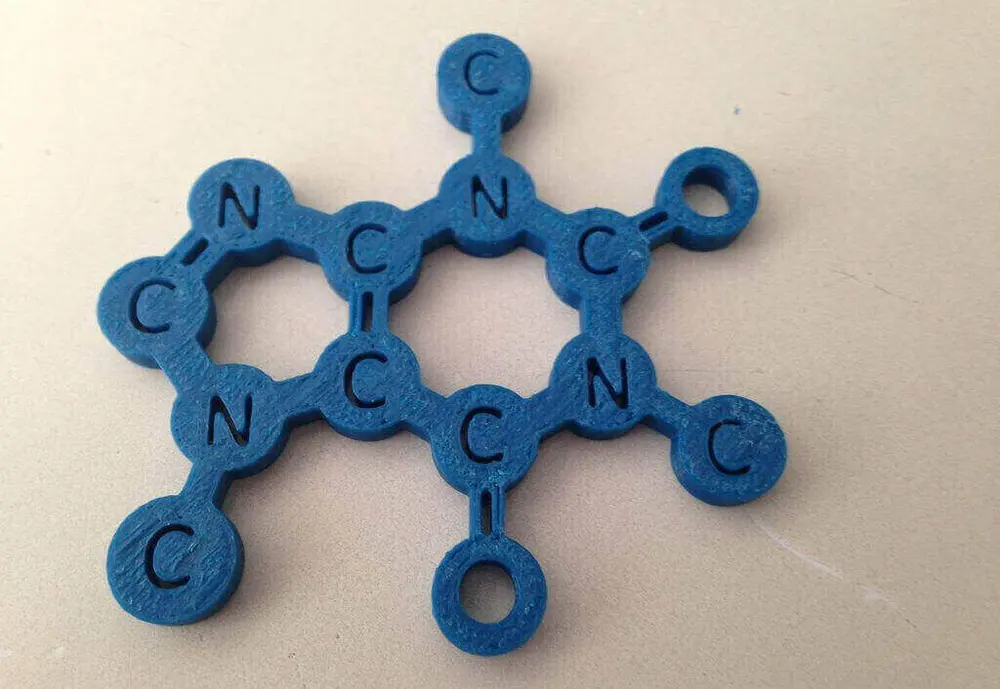

Jerome uses 3D printing to make personalized coffee coasters

Jerome is a caffeine fiend. He has a couple of coasters lying around his home and his office, and while they do the job, they look pretty dull.

In a coaster-jazzing mood, he decides to get creative with his beverage balancing disks and 3D prints this beautiful blue coaster in the shape of caffeine’s molecular composition. It took him a minute to find the design on the internet and less than an hour print the downloaded file.

The coaster lying on his table now serves as a fun and geeky sign that this table belongs to a Caffeine addict!

Linda puts useless jars to use with the help of 3D printing

We all have empty jars lying around in the house. Our hero in this short story is Linda, who decided that she must do something about them. So she designed plastic handles (using software) which fit tightly and securely onto the top of the jars. She then 3D printed the handles and converted the unused jars to functional drinking mugs.

Philip uses 3D printing to make toys for his son

Joe is 7 years old. He has been bothering his daddy, Philip, to buy him a computer game since the last few months. Philip realized that this is the perfect opportunity to teach his son the value of saving money and patience. He tells Joe “You can have the computer game, but you need to save up for it. Whenever you see loose change around the house, put it in a piggy bank. When the piggy bank is full, you can open it and use the money to buy the game”.

If you were an ordinary parent, you would probably go to a shop at this point and buy an overpriced piggy bank for your petulant progeny. Philip did it differently. Instead of going to a shop to buy the piggy bank, Philip downloaded a design file for a piggy bank from the internet and 3D printed it at home.

What Materials are Available for 3D Printing?

Since all of the above examples uses plastic like materials, you might be wondering if plastic is all that 3D printers can handle?

Not quite. Generally speaking, yes, but there are more options than you may think. Using a desktop printer you can 3D print using a wide variety of materials including plastics, nylon, metal and wood.

Note however that when you buy wood or metal filaments, you are essentially buying a plastic filament which has been coated or fused with metal or wood particles – it’s not 100% metal or wood. Doesn’t matter much though, because the end product still looks amazing.

Here are some examples.

Industrial 3D printers (much bigger and much more expensive) can also print with resins, ceramics, wax, paper and sandstones. Unless you have a huge wad of cash to burn and an empty room to fill, you cannot use these advanced materials for DIY projects. But you can leverage online 3D printing service such as All3DP’s Best Price 3D Printing Service to get your design printed in such materials and shipped to you.

If you are interested in knowing more about the variety of 3D printing materials, you should check out our 3D Printing Materials Guide 2017 – The Complete Overview

How do I get Started with 3D Printing?

3D printing is easy for anyone to learn. But before we hand you a shopping list and dive into nitty-gritty details, it is probably better to first take a brief look at the different steps in the 3D printing process. Once you understand the process well enough, you will be in a better position to start your journey and decide what you want to buy.

Step 1 of the 3D printing process : Design

If you want to 3D print any object, you need a digital design file encoding the three-dimensional geometry of the object. Therefore, design is the first important step of the 3D printing process.

So how do you create 3D design files? Do you have to be good at sketching or drawing in order to do so?

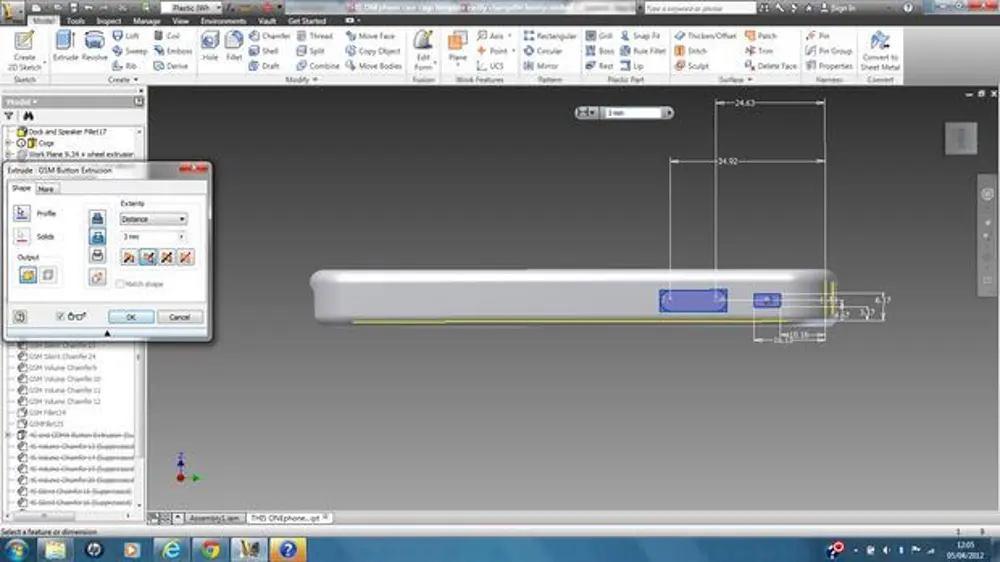

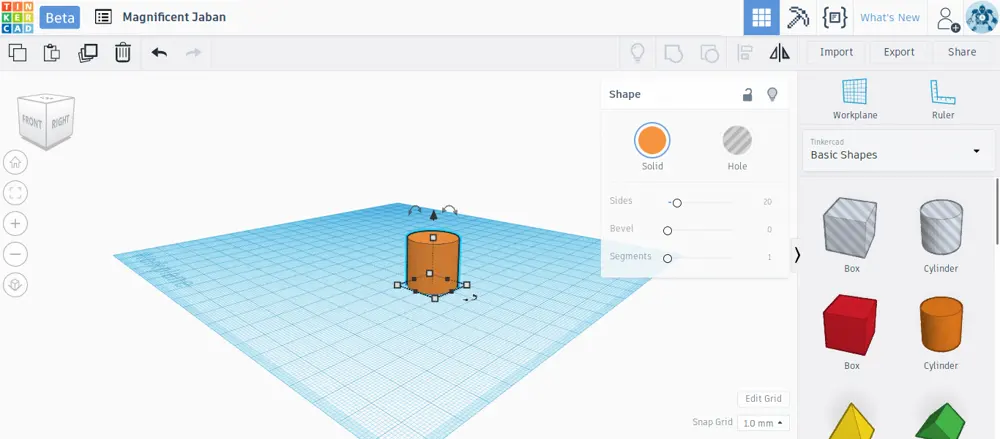

It turns out that anyone can design 3D objects! There is no drawing or sketching involved at all. You simply use CAD (Computer Aided Design) software. Using the tools and shapes available in the software, you build up your 3D object.

If you have ever worked with MS Paint, GIMP, Inkscape, Illustrator or Photoshop, then CAD software will seem familiar to you. They all feature similar click, select, drag and drop interfaces.

Here is a one minute video clip showing the design process for a beautiful ring so you can an initial impression of how it works:

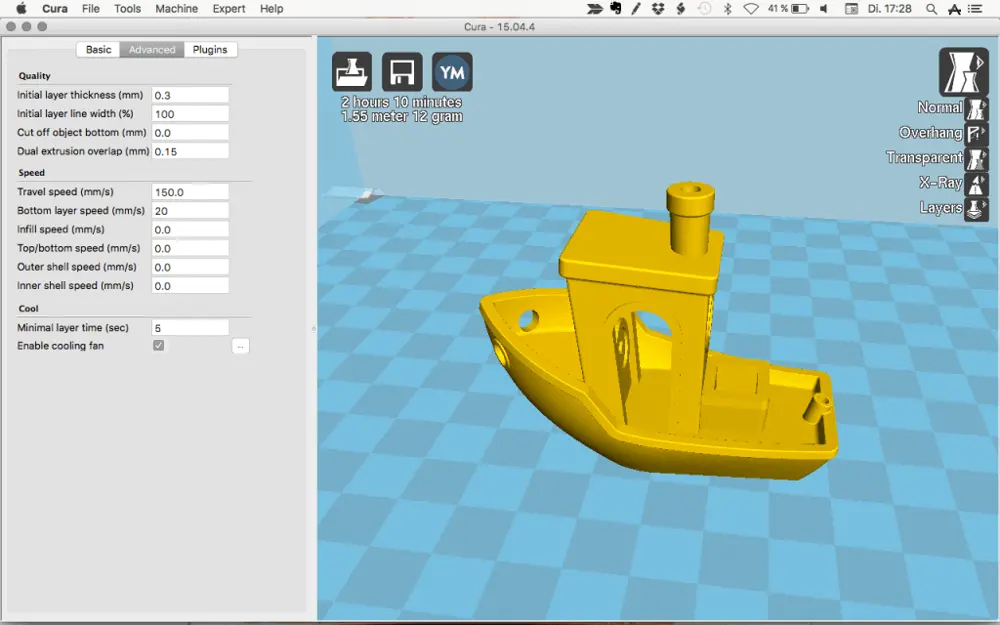

Step 2 of the 3D printing process : Slicing

Once you have the design file, the next step is to open the design in a dedicated slicing software (called a “Slicer”). The Slicer’s job is to process the 3D design and create a file containing instructions for a 3D printer to print your file. You can change settings in the Slicer to control various aspects of the printing process.

You might be wondering where the “Slicer” get its name? It turns out that one of the jobs of this software is to break down the 3D digital models into many stacked horizontal layers (slices). Hence the name!

It also plans the best way for the print head to move during the print phase so that it can create the first slice, then move upwards, then create the second slice and so on. Based on its calculations, it instructs the printer what to do in a language called G-Code.

It seems that a lot is going on under the hood of this innocuous looking software!

Step 3 of the 3D printing process : Printing

This is the simplest step of all. If you have a 3D printer connected to your computer, simply hit “Print” and watcht the magic happen. Alternatively, you will need to load your G-Code file onto a appropriate memory card for your printer.

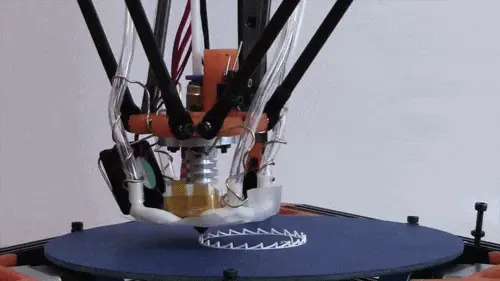

Regardless, you’ll now see your machine begin 3D printing, setting down its material layer by layer, building up into a physical object corresponding to your digital design.

3D printers are still somewhat slow and take several hours to print something like a coffee cup.

Here is a video of how this looks like:

What Skills do I Need to Make 3D Printing Work?

In the last few subsections, we looked at different steps in the 3D printing process. If you are a beginner, you might need to pick up some skills before you become somewhat good at each of these steps.

DESIGN SKILLS

If you want to design your own objects, it follows that you will need to familiarize yourself with 3D design software. Note that this is not an essential skill since you can always download designs from the internet.

Every CAD software is slightly different, so it is recommended that you choose one from the get go and try to get completely familiar with its interface and capabilities.

Thankfully, there are very good tutorials for almost all popular CAD softwares on the internet. Start with basic tutorials to build simple objects and when you feel confident with your knowledge, proceed to advanced tutorials dealing with more complicated objects. The bottom line is : if you have the will, you can become a decent designer in a matter of weeks.

In a later section, we will provide you with a series of links that will help you start your journey as a designer, if you are so inclined.

OPERATING THE SLICER AND PRINTER

Operating the slicer and printer is not always plug-and-play. Several things can go wrong and you need to be knowledgeable enough to troubleshoot and fix the common problems yourself.

1. You should be able to set up your printer and calibrate it before you can start printing your own designs. This process is not too difficult and each printer comes with its own instructions for assembly and calibration. Here’s an example of how this setup process looks like for aMonoprice dual extrusion 3D Printer.

2. Some 3D models can have overhangs. Since a 3D printer prints layer by layer, it cannot handle designs with too severe of an overhang. In this case, you have to create support structures using your slicer software so that those problematic areas can be printed. The support structure is printed differently using infills and they can be taken off after the print is complete. You need to be able to analyze a 3D model in your slicer and create the necessary support structure for a successful print.

3. Sometimes, even if the printer is correctly calibrated and the model has the correct support structures, the print quality is going to be terrible. This can happen due to several reasons. For example, the first layer may not stick properly to the print bed. The printing temperature might not be perfect for the material that you are using. If the material cools off too rapidly, this might lead to shrinkage or warping. You will need to understand these common issues and fix them by either changing the appropriate settings in your slicer or using other means. This is why it is extremely important to buy a 3D printer that is popular and has a good community willing to offer support in online forums.

4. We don’t mean to scare you, but this is just a tip of the iceberg. To see a complete list of things that may go wrong and how you can fix them, see our article on 3D Printing Troubleshooting.

HOW TO MAKE YOUR LIFE EASY BY DELEGATION

If you think that you are not ready to invest the time to pick up the necessary skills, we have good news for you! It is often possible to delegate a part of the 3D printing workflow to others.

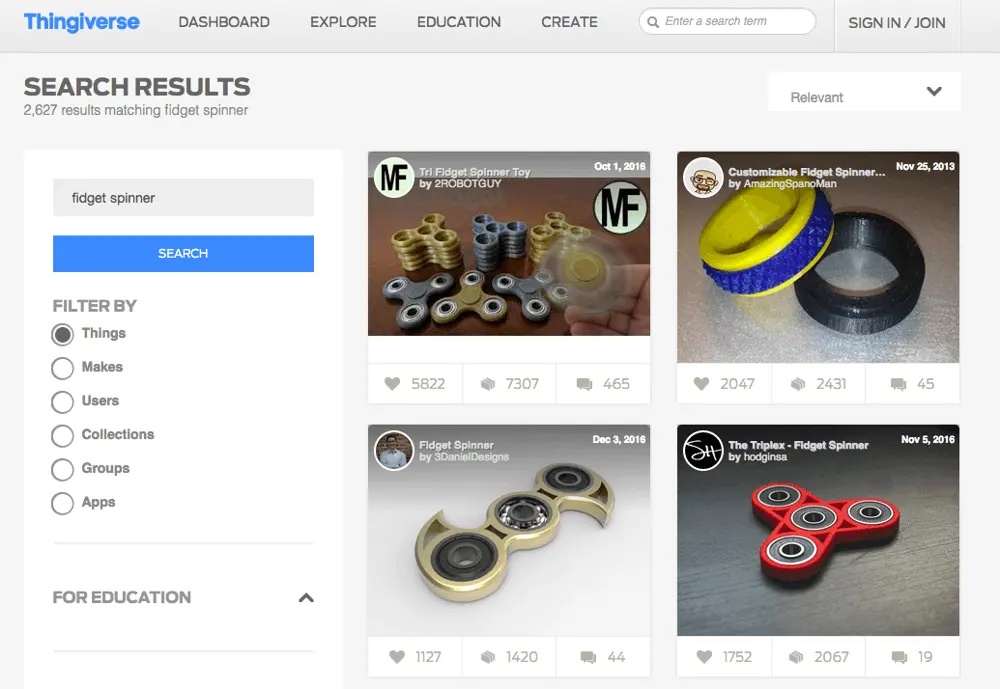

DOWNLOAD DESIGN INSTEAD OF DOING IT YOURSELF

Instead of designing the object yourself using CAD software, you can simply download an existing 3D model from the internet.

In fact, this is how most people do it. The good news is that the internet is brimming with free and open-source designs of almost everything that you might want to print. Thingiverse is the largest 3D file sharing platform and a good starting point for downloading 3D designs. We recommend that you check it out. There are plenty of other places offering interesting designs as well. To get a full picture, read our article The Best Sites for Free STL Files/3D Printer Models .

USE ONLINE 3D PRINTING SERVICES INSTEAD OF PRINTING IT YOURSELF

Did you know that you can enjoy most of the benefits of 3D printing without even owning a printer? Yes, that’s right. You can simply upload the design file to an online 3D printing service.

There are several such services. We have a webpage where you can compare prices from different 3D printing providers in one place. Simply upload the design, chose the material, select the provider and order the print. The 3D printing sevice will mail you the 3D printed object within a week. How cool is that?

There are several reasons why you might want to choose an online 3D printing service instead of printing it with your desktop 3D printers.

- You might want to print using materials not supported by desktop printers. Online 3D printing services use industrial 3D printers that can handle a wide variety of materials including thermoplastics, metals and alloys, resins, ceramics, wax, sandstone, paper, edible materials etc. With your desktop printer, you will usually be limited to thermoplastics, or thermoplastics with wood or metal dust.

- You might be primarily a designer, and do not want to go through the hassle of setting up and troubleshooting your own printer. You simply want to get a prototype fast and easily. In this case, online 3D printing services is definitely the way to go!

- Before you make the commitment to buy a 3D printer and go through the entire rigmarole yourself, you might want to test out the end product of 3D printing with a favorite design.

What do I Need to Start 3D Printing?

Finally, here’s a list of equipment and software which you should get to 3D print things:

1. CAD SOFTWARE

If you choose to design your own 3D models, then you need to get a CAD software.

The first step is to find the right software. There are many paid and free 3D modeling software out there. Some of them are targeted at beginners, some at intermediate designers and finally, some at expert designers. Since you are starting out, you should try out a simple software targeted at beginners. To help you choose, we have compiled a list of market leading 3D modeling software for beginners.

Once you have decided on a 3D modeling software, you can take a look at some of our 3D design tutorials for beginners. These tutorials will get you started with the respective software right away.

- How to 3D Print a Name Tag Using Tinkercad

- How to 3D Print Your Logo Using 3D Slash

- 3D Slash: How to Design a Cup for 3D Printing

- How to Make a Yo-Yo in Autodesk 123D

- Tinkercad Tutorial: 5 Easy Steps For Beginners

2. SLICER

Very often, the 3D printer manufacturer will include a slicer software in the package. In this case, you can simply use the included slicer.

If your printer’s manufacturer did not include a slicing software or if the 3D printing results are not satisfactory, try the free Cura slicing software. Cura was developed by Ultimaker, but it can be used with most desktop 3D printers out there.

If you’re willing to spend some money, go with Simplify 3D, the best 3D slicing software on the market.

If you want a full picture, here is an overview of the most popular 3D slicing programs out there: Best 3D Slicer Software Tools for 3D Printing.

3. 3D PRINTER

Finally, the most important component for DIY 3D printing – the printer itself. The most important factors to consider while buying a 3D printer are:

- Price : You can get something as cheap as the Wanhao Duplicator i3 Plus for around $350 or something as expensive as the Ultimater 3 for ten times that price ($3500).

- Size : For example, the Monoprice MP Select Mini is tiny and allows a ridiculously small maximum print size of 120 x 120 x 120 mm. On the flipside, there’s the Creality CR-10, which is a budget 3D printer offering print dimensions up to a cubic meter. Depending on how much space you want the printer to occupy on your table and what you want to print, you can choose your sweet spot and select accordingly.

- Material compatibility: Not all printers can handle all materials. You should always check the allowed materials for a printer before you buy it. Using incompatible materials may damage or break it, so you need to ensure that your material choice will be covered by the printer you buy.

- Technology: Desktop 3D printers usually one of the following two technologies : FDM (Fused Deposition Modeling) and SLA (Stereolithography). Without going too deep into the technologies, you should be aware that the print quality using these two techniques are different. Here’s a sample:

It’s quite obvious that SLA printers have better print quality. But they are also much more expensive than their FDM counterparts and require a great deal of post processing. With FDM you can pop your print off the bed and walk away. You need to make a choice accordingly.

Popularity and support: Finally, as we already covered earlier, setting up and troubleshooting your printer can feel like a lonely struggle unless there are online forums where you can ask questions and get answers within a reasonable time. Therefore, you need to ensure that your printer is popular and has an invested user base that will support you through your 3D printing journey.

With this information in mind, you can check out the following detailed 3D printer buyer’s guides.

- Beginner’s Guide on How to Buy a 3D Printer

- Best 3D Printer 2017 – The 18 Best 3D Printers and Reviews

4. PRINTING MATERIALS

Just like your Inkjet printer won’t work if you run out of ink, your 3D printer won’t work until you feed it some 3D printing material. So you better buy some!

When it comes to buying 3D printing materials, you have to first got through your 3D printer documentation and check which types of materials it supports. Most desktop 3D printers will support at least PLA or ABS plastic. Some 3D printers may support other types of plastics and composite materials containing wood, metal or stone.

Here is detailed guide into the different materials available for desktop 3D printers where you can get more information.

Once you’ve got your 3D printer, CAD software, Slicer and 3D printing material, you are all set. It’s time to rock and roll and start printing.

Who Uses 3D Printing?

For all the possibilities it offers, 3D printing is being used by a wide swathe of individuals, organizations and industries. From schools to college students, DIYers and designers, fields such as automotive, aerospace and medical.

Earlier we saw a few examples of how people are using 3D printing in ingenious ways at their homes. Let’s now take a deeper look at how 3D printing is being used by others in society.

Students

They say learning by doing is the best way to understand something. 3D printing is great way to bring this practical form of learning into the classroom. It allows students to create instead of being passive viewers or listeners, and to learn from their creations.

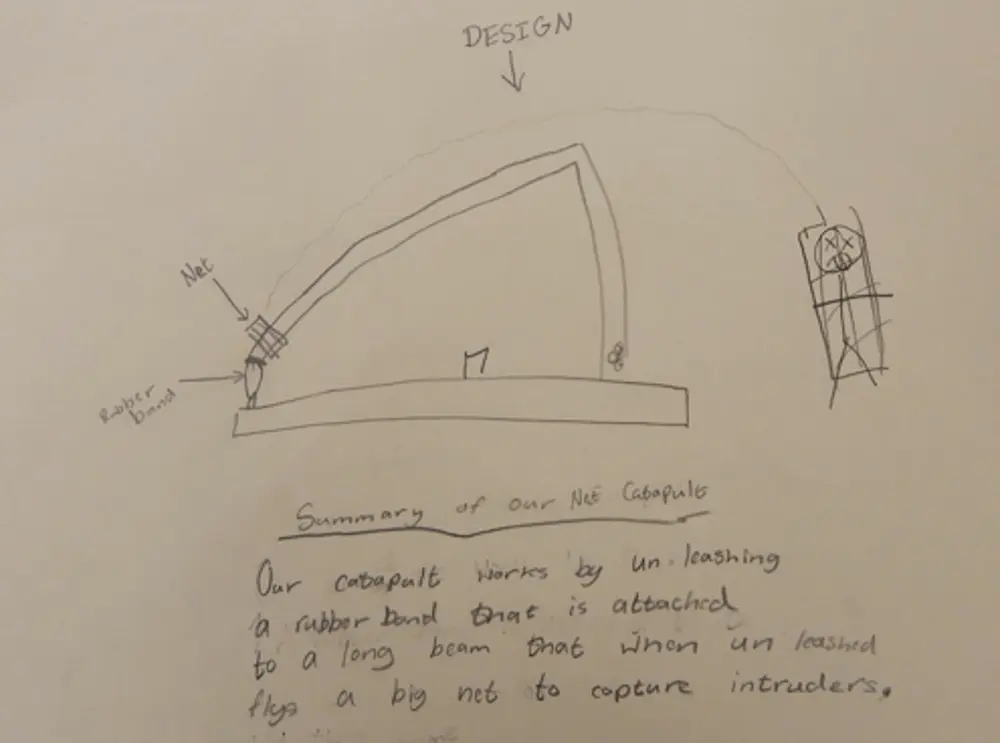

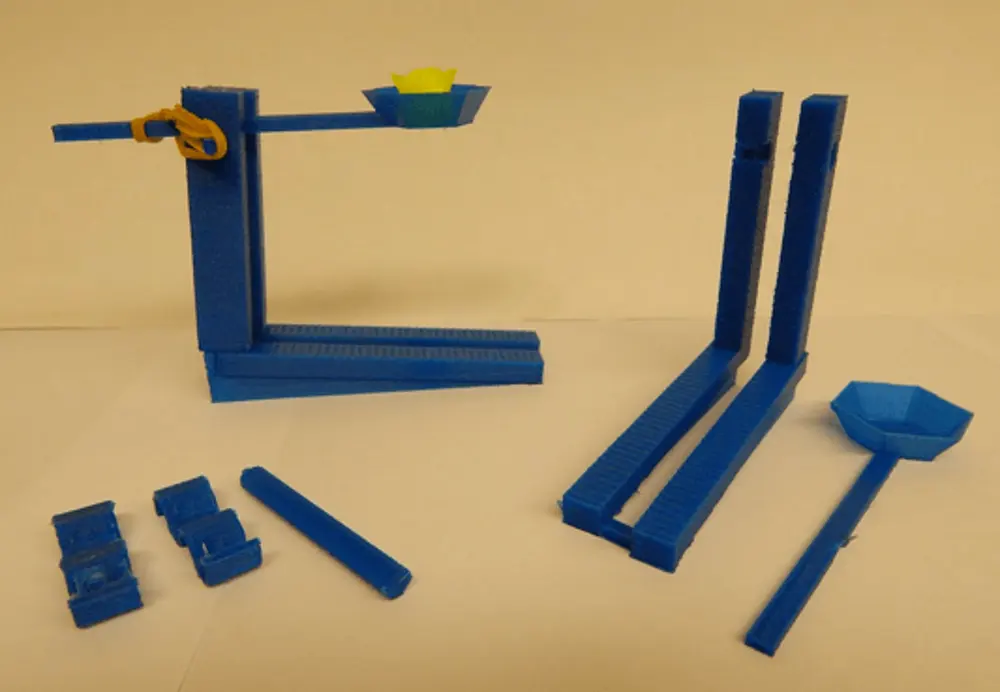

Brock Perkins, a fifth grade teacher at Winchester Thurston School in Pennsylvania, teaches a class on the Middle Ages. Students learn about the lives of the peasants and the nobility, castle structure and design, and they study siege machines like catapults and battering rams.

To help students learn about catapults and how they work, Mr. Perkins challenged his students to design their own catapults and create them using 3D printing.

“Luckily, our middle school students have extensive experience in Tinkercad, so they can help our fifth grade students with their creations.” – says the innovative teacher. After much trial and error (including resizing and flipping designs), the final catapults often look amazingly like the original brainstorming sketches.

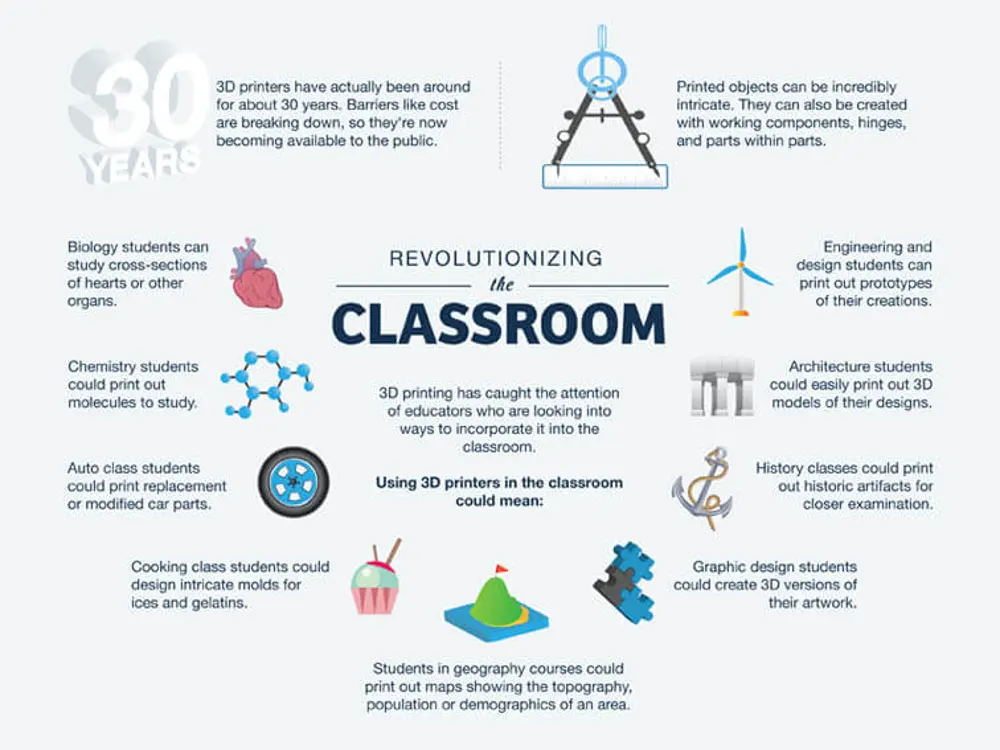

Brock Perkins is not alone. Many educators have already incorporated 3D printing in their classrooms. Here is an infographic which illustrates all the different ways in which 3D printing is being used in schools and universities.

DIYers

DIY stands for Do It Yourself. DIYers have an urge to solve their own problems, often cheaply and ingeniously, instead of looking for readymade market solutions. They are those people that can build a computer out of its components. They can fix a broken door handle knick-knacks using things lying around in the house.

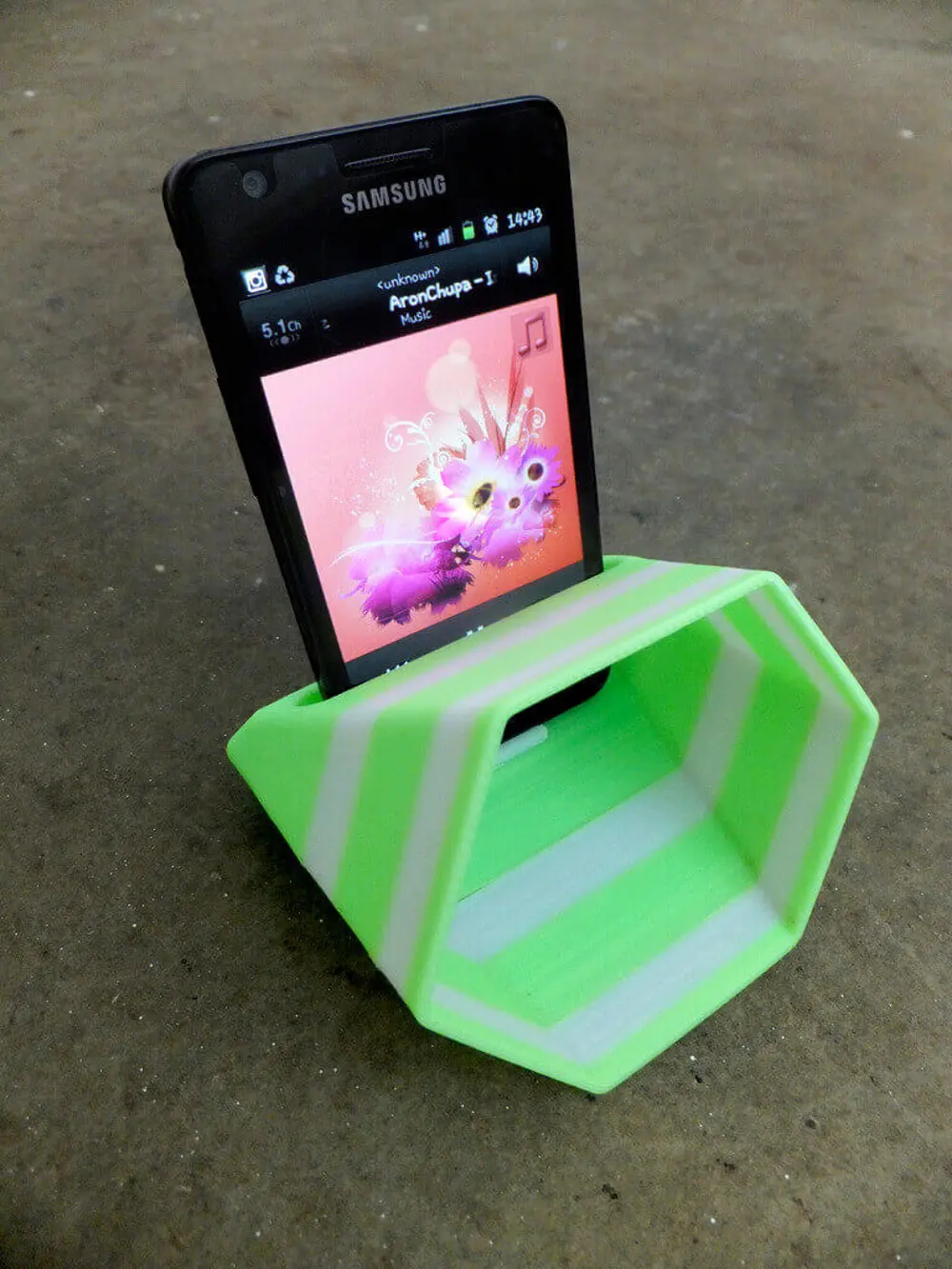

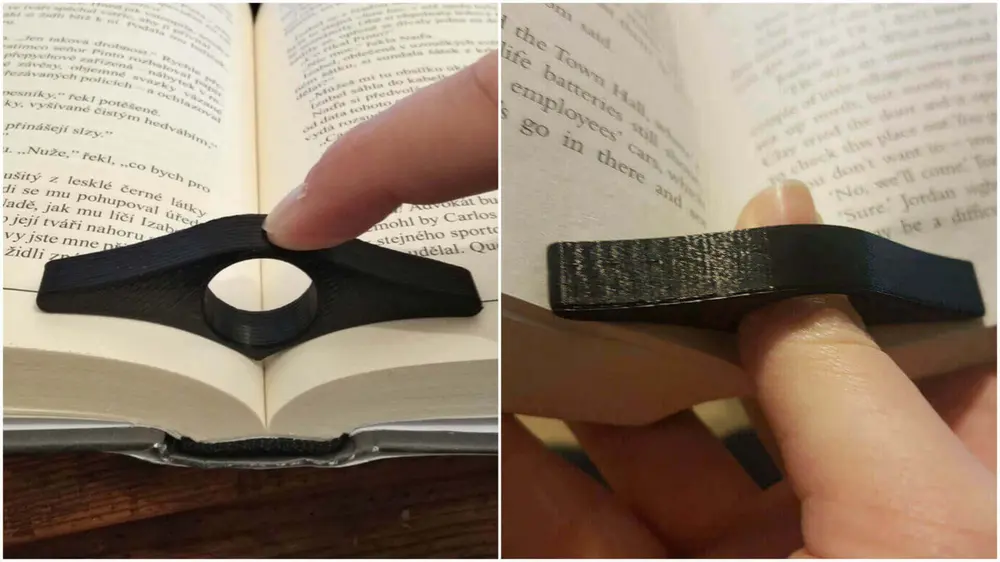

It is no wonder that DIYers have embraced 3D printing. They are using the technology to make everything from smartphone amplifiers to a one-handed book holder. Take a look:

Designers

Designers use 3D printers to quickly create product models and prototypes, but they’re increasingly being used to make final products as well. Among the items made with 3D printers are shoe designs, furniture, wax castings for making jewelry, tools, tripods, gift and novelty items, and toys.

In the industry

The biggest user of 3D printing is, of course, industry. Let’s take a brief look at which industry players have adopted 3D printing and how they are using it to transform their manufacturing processes.

CAR AND AEROPLANE MANUFACTURERS

Formula 1 racing teams are using 3D printing for prototyping, testing and ultimately, creating custom car parts. Swedish car manufacturer Koenigsegg uses 3D printing to manufacture the variable turbocharger for their One:1 model. GE Aviation and Safran have developed a method to 3D print fuel nozzles for jet engines, which allows them to replace complex assemblies with a single superior part.

DOCTORS AND DENTISTS

Doctors and dentists use 3D printing for creating aids and replacements that need to be customized for their patients.

Hearing aids, dental braces and prosthetic hands can be easily customized for the patient using 3D printing, avoiding any manual labor. In fact, most hearing aids that you see today are 3D printed!

CHEFS AND FOOD MANUFACTURERS

3D printing using edible materials is allowing food makers to explore the customization of their otherwise mass-produced and commoditized products.

For example, Barilla’s pasta making 3D printer allows users to create pasta of never-before-seen shapes and sizes. In early 2015, Dutch supermarket Albert Heijn launched a chocolate extruding printer in its bakery department, expanding custom cake-decorating services. Even NASA are getting in on the act with pizza printed in space.

The possibilities seem truly delicious. In fact, so much so that we have a dedicated guide just to 3D printing food.

FASHION GURUS

With 3D scanning, it’s possible to create fashion that fits anyone perfectly. Imagine shoes, glasses and clothing that adapt to you. Fusing traditional materials with modern 3D printed elements also creates clothing with a whole new edge.

For example, did you know that Adidas has been making 3D printed shoes for quite some time now? The company, and many other shoe manufacturers, want to push the boundaries of 3D printing and mass produce shoes with this technology.

You can now also design and print your own jacket, thanks to this innovative website from fashion maverick Danit Peleg .

ARCHITECTS AND CONSTRUCTION COMPANIES

Before 3D printing, architects had to construct scale models in a laborious and manual process to communicate their design intent. Today, they can quickly and easily create 3D printed scale model directly from their existing CAD data that is used for developing blueprints.

3D printers may also be used to make future buildings. A Chinese company called WinSun Decoration Design Engineering has already 3D printed a number of houses. Produced using a vast material extrusion 3D printer, these include a 1,100 square meter mansion and a five story apartment block.

What are the Alternatives to 3D Printing?

ALTERNATIVES FOR HOUSEHOLD USE

When it comes to household manufacturing, you want something that is cheap and small. At this point in time, 3D printing is the reigning champion of this interesting space, being not too pricey and not too big.

A small but slightly more pricy alternative is a desktop CNC machine. CNC milling is a subtractive manufacturing technique, which means you start with a big block of material and then cut material away, sculpting it to produce the target object. CNC stands for Computer Numerical Control, which means that they operate under computer control, just like 3D printers.

The objects can be designed using CAD sofware. The computer reads the CAD file and instructs the cutting tool in the CNC machine on how to move in order to sculpt the physical object from the slab.

Let’s take a look at how this works.

While desktop CNC machines are generally more expensive, they have some advantages compared to 3D printing. They can work with a wider range of materials at the same price point including metal alloys (e.g. aluminum, steel alloys, brass, copper), softwoods and hardwoods, thermoplastics, acrylic, modeling foams and machining wax (for creating a positive model for casting). The end result is precise. CNC machines are also much much faster than 3D printers.

On the downside, they are very noisy. CNC machines work by using a high speed rotating cutting tool to cut away unnecessary parts from a block of materials. As a result, they create a huge mess during operation, spurting away material in every direction. The subtractive manufacturing technique employed in these machines also means that a lot of material is wasted.

Here are two notable examples of desktop CNC machines successfully funded via Kickstarter.

- Nomad 883 CNC Mill, cost: $2,599

- Othermill, cost: $2,199

For a more detailed comparison, check out 3D printing vs CNC : Explained and compared.

COMPARISON WITH INDUSTRIAL ALTERNATIVES

3D printing is a much newer technology compared to traditional manufacturing techniques such as Metal Casting or Injection Molding. There are definitely a lot of inherent advantages to 3D printing, which is why so many industrial sectors are exploring it for prototyping and manufacturing. But all in all, it still lags behind the more traditional methods. Here is a rundown of how they compare.

Comparative advantages of 3D printing over traditional methods

- Possible to manufacture very complex designs: 3D printing lets manufacturers print very complex designs. Such designs are either very expensive or impossible to manufacture using traditional methods.

- Easy customization: In traditional manufacturing, customizations lead to additional manufacturing costs. It is much cheaper to produce standardized items in bulk amounts. In 3D printing, there is no added manufacturing cost to customization. You simply customize the digital 3D model and there is no need for additional tooling. Therefore each item can be customized to meet specific needs of the user.

- Lower fixed costs: With methods like Metal Casting or Injection Molding, each item requires a new mold. In contrast, since 3D printing is a “single tool” process, there is no need to change the production process for new items. This leads to significantly lower fixed costs per model.

- Speed and ease of prototyping means faster and less risky product development: 3D printing doesn’t involve expensive tooling. It’s a particularly cost effective method for designers to test the market, do small production runs or launch their product via crowdfunding. It is also less risky as it is relatively easy to change designs at the prototyping phase without compromising more formal and expensive manufacturing orders.

- Less waste: Most traditional methods are subtractive. This means a lot of material is wasted during the manufacturing process. On the other hand, 3D printing is an additive process. It only uses as much material as needed for making the model. Most of the 3D printing materials can also be recycled and repurposed into more 3D printed objects.

Comparative disadvantages of 3D printing over traditional methods

- Higher cost for mass production: When it comes to manufacturing a single item in large quantities (more than 1000 to 10000 units), traditional manufacturing beats 3D printing hands down in price. While 3D printing has a lower fixed cost per item, this advantage completely disappears during mass production as the fixed price is counted just once. But as the price of 3D printers and materials continue to decrease, this balance might shift in the future.

- Less choice of material, color and finish: Traditional manufacturing can handle a much wider range of materials, colors and finishes compared to 3D printing.

- Limited and non-reproducible strength and endurance: Since 3D printing is a layer by layer additive manufacturing process, a common problem is varying part part strength and endurance across layers. The technology is also not completely reproducible yet, because different machines produce parts with slightly different properties.

- Lower precision: Take a look at your computer, smartphone or your music player. See how precise they are? Perfectly rounded or angular edges, perfectly smooth polished surfaces – these are a result of traditional manufacturing processes. While 3D printers are slowly catching up, the best ones offering precisions of 20 – 100 microns, they still need some more time before they can become as immaculate as their rivals.

The verdict is that 3D printing is definitely the winner for prototyping and highly detailed or customizable parts, but when it comes to mass production of simple things with strict quality controls, old-school is the way to go.

What does the future hold for 3D printing?

The big dream

The big dream of 3D printing is “Walmart or Home Depot in the palm of your hands” or “A factory in everyone’s house”. That notion may thrill or frighten you, but there is no denying that owning a machine which can churn out infinitely customizable things on a whim is extremely attractive.

With a 3D printer at home, think of the money you will save by short circuiting inventory and transportation costs that are bundled in everything that we buy.

Think of getting a replacement part for a broken utility in a matter of hours instead of waiting for the part to arrive from a distant location.

Imagine the creative freedom of making every mundane household item personalized to your own taste and preferences. Imagine the joy of wearing a shoe designed to fit just your feet and no one else’s.

It will be a different world – much like the computer and the smartphones have empowered billions of people, 3D printers might do the same for manufacturing.

A lot of 3D printing enthusiasts say that 3D printers will soon be an integral part of every household, shifting the balance between manufacturers and consumers. Others say the technology is not there yet, and that the technologies true value lies exclusively in the industrial sphere. All we can do is watch closely and speculate.

What could hold 3D printing back?

There are also several arguments against widespread adoption of 3D printing.

Operating CAD software and 3D printers still requires technical knowledge that the ordinary consumer will not want to bother themselves with. If they don’t, then 3D design will remain monopolized in the hands of experts, reducing the value add of infinite customization. You will still be able to download designs from the internet and use simple software to tweak an existing design, but you won’t be able to design personalized parts as you please.

Perhaps the biggest limitation of 3D printers are their current capabilities. The range of materials, while growing, still isn’t wide enough to meet the vision of infinitely customizable anything.

Similarly, the ability to print multiple colors and materials into the same print — while possible on a handful of machines today — is not nearly widespread enough.

We know that many (if not almost all) useful things use multiple materials and multiple colors. For end use products, 3D printers will not be seen as useful until they can evolve to handle this complexity.

But there is a glimmer of hope. Approaching desktop price and usability is the recent news that XYZ Printing has announced a full-color desktop 3D printer, priced at around $3000.

We might still be far from the day when people will 3D print iPhones in their home, but we live in hope.

Reuse and recycle

Even if 3D printers don’t revolutionize the household at the scale of personal computers, it is almost certain that it will be a great force of good in the future.

We are slowly approaching a time when recycling is a matter of necessity rather than luxury. How many things do we discard and throw out today because an essential part got broken and it’s too hard to find a replacement? With a 3D printer, it is already possible to design and replace many simple parts on demand, rather than by batch.

We believe that in the future, forward thinking people will increasingly 3D print and fix their household objects instead of throwing them away. Even if they don’t do it in their own homes, they could do so in a shared 3D printing facility near their homes.

Future of 3D printing in the industry

So much about households. But what’s going on at the industrial front?

It turns out that some big household names are very much active in the 3D printing market. GE purchased two European 3D printing companies for 1.4 Billion dollars. HP, the printing giant, introduced their own 3D printing technology and printer.

Giants aside, 3D printing is making steady progress both horizontally and vertically in the industry.

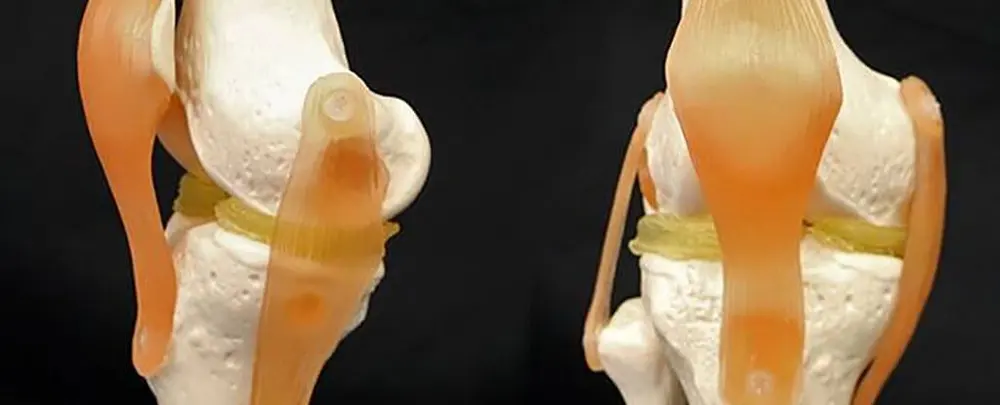

Many new materials are becoming available for 3D printing and this is continually expanding the possibilities of 3D printing and spurring new use cases. For instance, researchers at Duke University recently developed a 3D-printed gel that mimics human cartilage when dried. This is proving to be very useful for knee replacement surgeries.

Printer manufacturers are improving the capabilities of their machines to fix current limitations of size, accuracy and consistency. For example, Ford and Boeing are currently testing the Stratasys Infinite Build, a 3D printer that can print objects of infinite length!

The cost of metal printing is coming down, spurring many companies who stayed away earlier because of the prohibitive costs, to adopt 3D printing for prototyping. Automotive and aerospace manufacturers are increasingly using 3D printing to print end products, not just prototypes.

Customizable 3D printed products are on the rise, especially in the medical industry. Remember the tray of plastic goo your dentist stuck in your mouth to make a model of your teeth? Now an orthodontist can simply 3D scan of your teeth instead. The scan is used to make a digital model. With the help of Invisalign, a product from Align Technology, this can be used to customize your mouthpiece!

A technology that inspires

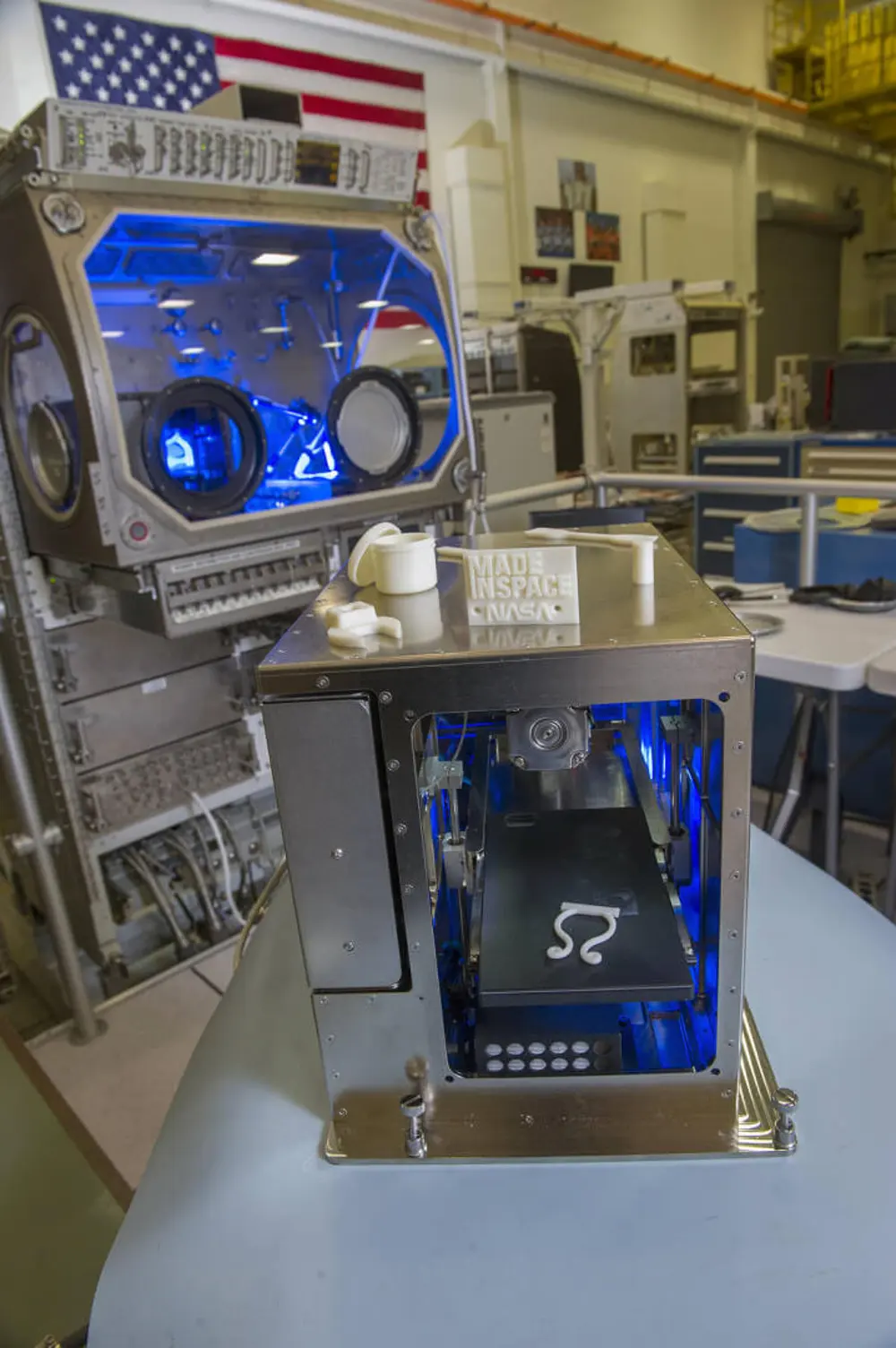

3D printing is also going to outer space! NASA has already put 3D printers on board the International Space Station.

Why are 3D printers so useful in outer space? Consider the case of the Apollo 13. To prevent astronauts from dying of carbon monoxide poisoning, NASA had to find a way to fit a square peg into a round hole. If there was a 3D printer on board, they could have easily solved the problem by designing a connector and printing it.

Astronauts can’t haul an endless supply of parts with them. So it’s always a challenge when a valve or widget breaks down and needs a replacement. A 3D printer on board could easily fabricate and fix broken parts as needed.

The long term plan for NASA (or should we say SpaceX?) is to leverage 3D printers in habitats on Mars and other worlds, because we most likely wouldn’t be able to ship a Home Depot along with the people. 3D printers will be humanity’s saving grace in the stores absence.

Much closer to Earth, humanitarian organizations are experimenting with 3D printing in regions afflicted by floods, hurricanes and earthquakes. In disaster stricken zones, it is quite difficult to transport essential survival equipment. So these organizations (in particular, a startup called Field Ready) have set up 3D printing facilities nearby which prints the required items on the fly, with minimal need for transportation. Much more on this in our article on the recent Texas hurricane disaster.

A bright future

From households to the industry to disaster zones, 3D printing is transforming the world for the better. The future looks extremely bright for this technology and the benefits it will bring us. In fact, the future is so bright, that we might all need some 3D printed sunglasses real soon.

Wrapping Up

Hope you enjoyed this tour of the world of 3D printing. It truly is an exciting industry brimming with innovation and possibility. We hope that we have been able to transmit some of that excitement to you.

For a deeper dive into the ins and outs of 3D printing, check out our in-depth article on the subject: The Ultimate Guide to 3D Printing – 101 Questions Answered.

If you liked this article, spread the word and let people know about this amazing technology. Don’t hesitate to write to us in the comment section if you have any questions or remarks.