The complete updated buyer’s guide to the best SLS 3D printers. Plus, learn about SLS technology, 3D printing services, applications, and SLS materials.

Prized for its ability to create engineering-grade parts with excellent mechanical properties and fine resolution incredibly fast, SLS (selective laser sintering) 3D printing is what engineers and industrial designers turn to for functional rapid prototypes and end-use parts.

Advancements in technology have made SLS printers more affordable and compact. Not long ago, all SLS machines were bulky and expensive. There are now a good number of office-friendly benchtop SLS 3D printers on the market, and even industrial-size machines have become less costly compared to traditional fabrication techniques.

If you’re looking to buy your first SLS 3D printer or upgrade to a more powerful version, this updated buyer’s guide takes a deep dive into the technology and the latest desktop and industrial-scale SLS printers on the market. We’ll also explore what third-party SLS 3D printing services have to offer and why it may be a good idea to take SLS printing for a spin before investing in a machine.

Why choose SLS?

SLS 3D printing uses high-powered lasers to fuse powdered plastic material together into 3D shapes. It can create parts that are finely detailed, strong, durable, heat resistant, and flexible (when needed) all at once.

Printer manufacturers often boast that SLS prints rival injection molding products in terms of strength and precision. When compared to injection molding, 3D printing can create parts that have internal channels, lattice structures, and other features not possible with molding.

SLS also offers a high degree of predictability in material and mechanical properties, so it’s popular in aerospace, medical, and regulated industries. Furthermore, SLS printing is mostly support-free, which expands your ability to design and produce very complex geometries.

The technology is popular for functional prototypes, design evaluation models, small manufacturing runs, end-use consumer products, and product testing, among other uses. Industries that have taken a particular shine to SLS include:

- Automotive (jigs & fixtures, prototype cars)

- Aerospace (prototypes, tools, air ducts)

- Medical and healthcare (prosthetics)

- Consumer electronics (housings, prototypes)

- Military (replacement parts, grips)

- Heavy Industry (sand casting patterns, tooling)

SLS 3D printing is more widely used today, but it’s not a perfect technology. Despite its advances, SLS printing is still relatively expensive and powder handling can be messy when done by hand (although some vendors offer enclosed solutions).

Add-on depowdering units – like the Formlabs Fuse Sift – cut down on the mess, but they will naturally bring up the total cost of your SLS investment. Higher-end and industrial-level machines can offer depowdering solutions as default, but again, they will also require the buyer to dig deeper.

On the plus side of things, much of the loose powder can be recycled, which lowers material costs and makes SLS a more sustainable technology than injection molding or machining. And, compared to the tools needed to create single or short-run of custom parts and prototypes by injection molding, SLS 3D printing usually comes out as the more affordable solution.

All in all, SLS 3D printing is a powerful technology for the right applications. Whether it suits your purposes depends entirely on the design of your parts, the material requirements, and the application itself. Keep these factors in mind as you read on, and find out which printer is right for you.

OVERVIEW

| 3D Printer | Max. Build Volume (mm) | Min. Layer Thickness (mm) | Print Speed | Laser Type | Materials | Market Price |

|---|---|---|---|---|---|---|

| Sintratec Kit | 110 x 110 x 110 | 0.1 | 5-20 mm/s | Laser Diode | PA 12, TPE | $5,999 |

| Formlabs Fuse 1 / Fuse 1+ 30W | 165 x 165 x 300 | 0.11 | 10 mm/h | 10W Ytterbium Fiber Laser | PA 12, PA 11, Glass Filled PA 12 | $18,499 / $27,500 |

| Sintratec S2 | 130 x 130 x 360 | 0.1 | 15 mm/h | Fiber Laser | PA 12, TPE | $38,000 |

| Sinterit Lisa X | 180 x 130 x 330 | 0.075 | 14 mm/h | 30W Infrared | PA 12, PA 11, PA 11 CF, TPU, TPE, PP | Estimated $40,000 – $50,000 |

| Sharebot SnowWhite 2 | 100 X 100 X 95 | 0.05 | 35 mm/h | 14W CO₂ | PA 12, PA 11, TPU, reinforced powders | From $40,000 |

| Wematter Gravity | 300 x 300 x 300 | 0.1 | 10 mm/h | – | PA 12, PA 11, PP | From $120,000 |

| XYZprinting MfgPro236 xS | 230 x 230 x 250 | 0.06 | 22 mm/h | 60W CO₂ | PA 6, PA 11, PA 12, PA 11 CF, PP, TPU | N/A |

| Nexa3D QLS 350 | 350 x 350 x 400 | 0.05 | up to 8 liters/h | 4x100W CO₂ | PA 11, PA 12, PA 6, xPBT (Polybutylene Terephthalate), glass-filled | $500,000 |

| Sinterit NILS 480 | 200 x 200 x 330 | 0.075 | 10 mm/h | 30W Infrared | PA12, PA11, PA11 CF, TPU, TPE, PP | $80,000 |

| Prodways Promaker P1000 X / S | 300 x 300 x 360 | 0.06 | 2 liters/h | 60W CO₂ | PA 12, PA 11, TPU, PP | From $100,000 |

| 3D Systems SLS 380 | 381 x 330 x 460 | 0.08 | 2.7 liters/h | 100W CO₂ | Duraform ProX PA, Duraform ProX HST Composite | N/A |

| Farsoon eForm | 250 × 250 × 320 | 0.06 | 0.8 liters/h | 30W CO₂ | PA 12, PA 11, PA carbon fiber, PA glass filled, PA 6005, PP | $114,000 |

| Eplus3D EP-P3850 | 380 x 380 x 500 | 0.1 | – | 55W CO₂ | PA 11, PA 11 carbon fiber, PA 12, PA 12 glass filled | $150,000 |

| EOS Formiga P 110 Velocis | 200 x 250 x 330 | 0.06 | 1.2 liters/h | 30W CO₂ | Alumide, PA 1101, PA 1102 black, PA 2200, PA 2201, PA 3200 glass filled, PrimeCast 101, PA 2105 | $170,000 |

| Sindoh S100 | 510 x 510 x 500 | 0.06 | 4.7 liters/h | 2x100W CO₂ | PA12, PA11, TPU, PP | $650,000 |

DESKTOP SLS 3D PRINTERS

Over the past few years, the SLS 3D printing market has been revolutionized by the emergence of desktop and benchtop-sized machines. Unlike their industrial counterparts, these compact 3D printers are much more accessible and affordable. Here are some of the best desktop SLS 3D printers on the market.

Sintratec Kit

You can usually cut costs on your 3D printer purchase if you settle on a DIY kit. Sintratec Kit is the world’s only build-it-yourself SLS 3D printer kit, and perhaps the most affordable option in the SLS category.

At a cost of around $6,000, this system presents itself as an ideal option for frugal small businesses that want to explore the possibilities of SLS 3D printing technology. Although the price is quite low compared to other SLS machines, keep in mind that this is a kit in every sense of the word, and will take around four days to build and install.

The Sintratec Kit offers a 110 x 110 x 110 mm build volume and a minimum layer height of 100 microns, making it capable of producing complex geometries at a decent resolution.

Formlabs Fuse 1 / Fuse 1+ 30W

We — along with everyone else — had been eagerly waiting for the Formlabs Fuse 1 since 2017. We finally got to feature it on this list last year, and it definitely belongs here also in 2022.

The Fuse 1, starting at $18,499 ($32,000 for the printer and the Fuse Sift depowdering station), features a touch user interface, with live stream monitoring of the print bed layer by layer. Formlabs says its Surface Armor technology forms a semi-sintered shell that prints around the surface of the part, providing good mechanical properties and a high-quality surface finish.

Fuse 1 has a build volume of 165 x 165 x 300 mm and a layer thickness of 110 microns. Combined with the Fuse Sift, it can provide a 30% powder refresh rate, driving down material costs. It’s a great option for manufacturers looking for affordable high quality.

In July 2022, Forlabs launched another version of the Fuse called the Fuse 1+ 30W, which it says is twice as fast. The latest version features a laser that’s 3x more powerful and a host of other features to boost production speed and output. The Fuse 1+ 30W can also print with carbon-fiber infused PA 11.

Sintratec S2

The Sintratec S2 is a compact SLS 3D printer that, combined with its post-processing stations, provides a studio-friendly solution for high-detail batch printing. This machine offers a surprisingly large cylindrical build volume of ⌀160 x 400 mm. Unlike the Sintratec Kit, the S2 does not require days of building before you can print.

Quality control of prints in progress comes by way of an integrated 4K camera, giving layer by layer oversight. The manufacturer promises fast print speeds and high accuracy.

Part of an SLS 3D printing ecosystem, Sintratec’s S2 maximizes efficiency using swappable modules for powder handling, in addition to a suite of accompanying stations that cover material handling, material reclamation, plus post-processing in the form of blasting and polishing.

Sinterit Lisa X

We mentioned last year how Sinterit, a Polish 3D printer manufacturer, had built on its previous Lisa machine and introduced the Sinterit Lisa Pro. Well, now they’ve done it again with the launch of the Lisa X.

Lisa X takes what made the Lisa Pro good and makes it better. After her makeover, Lisa now offers a larger maximum print size (180 x 130 x 300 mm), a more powerful laser (30W vs. 5W), a wider material selection, and much faster print speeds. The new printer is up to 12 times faster than the Lisa Pro and can finish most print jobs in 24 hours, according to the manufacturer.

What’s amazing is that the speed doesn’t come at the cost of detail quality. The Lisa X has the same 75-micron minimum layer height as its predecessor. The machine supports nine materials from Sinterit, but its open platform allows easy use of third-party powders as well.

The Lisa X is marketed as a compact SLS printer, but it’s really bridging the gap between compact and industrial 3D printers. We don’t know the exact price yet, since the printer is all-new, but it’ll probably fall around $40,000-$50,000. The Lisa Pro is also still available in the Sinterit catalog.

Sharebot SnowWhite 2

Sharebot SnowWhite 2 is an upgrade to the company’s previous SnowWhite unit. Its CO₂ laser gives it the ability to print with a wider range of materials, including PA 12, PA 11, TPU, and reinforced powders that contain additives like carbon fiber, glass, and aluminum.

Geared towards research centers and R&D departments, the SnowWhite 2 is easy to use with an autonomous “one click” user interface. It features an improved temperature control system, heating up to print temperature in just 15 minutes and providing high durability and surface detail. It also has an optional atmosphere control module that is compatible with both nitrogen and argon and eliminates yellowing in printed parts.

Priced at just under $40,000, this system is relatively expensive compared to other benchtop machines. It has a petite 100 x 100 x 95 mm build volume, making it one of the smallest SLS 3D printers on the market.

While the cost of SnowWhite 2 might seem a bit high for a system that is so limited in size, the real value of the Sharebot SnowWhite 2 lies in its ability to print with a variety of thermoplastic powders, enabling users to produce mechanically superior prototypes and end-use parts.

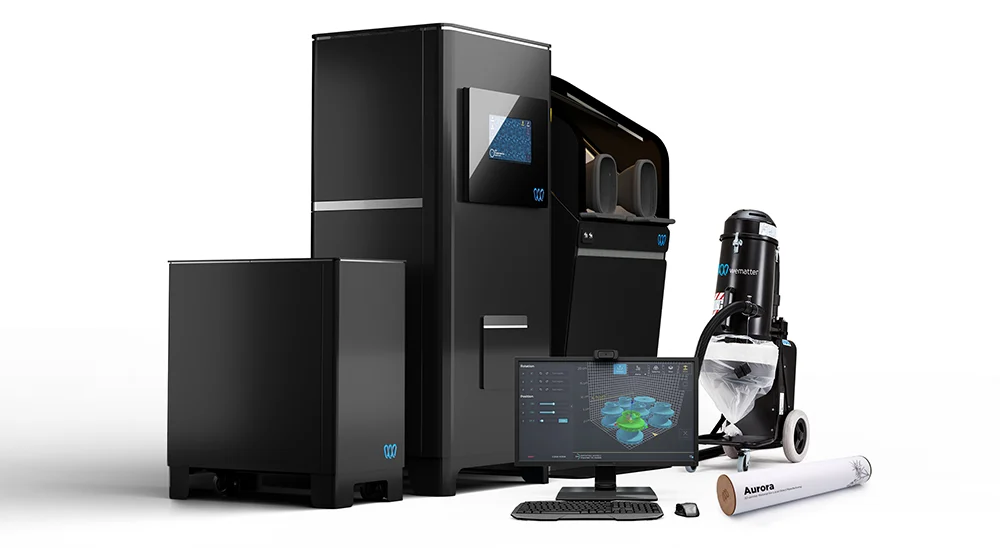

Wematter Gravity

Sweden’s Wematter launched an updated version of its Gravity SLS 3D printer last year. This newest Gravity iteration introduces a lengthy list of improvements. Among them are a new re-coater with increased durability, better temperature control for a more stable printing process, the ability to print even thinner walls, and ability to print in PP.

The Gravity has a well-sized printing volume at 300 x 300 x 300 mm. It’s easy to operate thanks to an intuitive touch screen. Wematter also provides a cloud-based operating platform that requires no installation.

The company’s proprietary powder filling system empties a powder container into the machine in a matter of seconds. Wematter also offers a curious unit called the Atmosphere that provides “improved control of build chamber conditions.”

The Atmosphere communicates with the Gravity’s software and creates a more stable thermal environment during the printing process. This optional unit boosts the Gravity’s performance for increased part density, surface finish, and mechanical performance, claims Wematter. The Gravity isn’t available for purchase, and is instead delivered as a subscription-based printer-as-a-service rental.

INDUSTRIAL SLS 3D PRINTERS

Although a flurry of benchtop-sized SLS machines have recently entered the market, most SLS systems reside in industrial spheres. Here are a few of the best SLS 3D printers made for industrial use.

XYZprinting MfgPro236 xS

Towards the end of last year, XYZprinting introduced and launched the MfgPro236 xS, a more advanced machine than the MfgPro230 xS we featured previously. The new printer comes with a marginally larger build volume of 230 x 230 x 250 mm and doubles the laser strength to 60W.

This new machine is capable of printing smaller details than the previous one, and it’s also slightly faster. The detail and speed, combined with the decent chamber size, make it a good option for industrial-scale SLS printing.

A large material library further makes the MfgPro236 xS a very versatile printer capable of excelling in multiple applications. It’s also an open platform, so it supports materials from third-party manufacturers.

The MfgPro236 xS, like its predecessor, uses two software suites, Buildware and XYZprint AMSLS. Buildware build enables operators to control the model sintering process directly, while AMSLS lets them check on their prints and plan sintering projects remotely.

Nexa3D QLS 350

Nexa3D QLS 350 is an open platform SLS 3D printer that looks to provide unrivaled speed, printing up to 8 l/h. The machine achieves this speed with four 100W CO2 lasers.

With a removable build unit of respectable size (350 x 350 x 400 mm volume), the printer lays claim to very high capacity utilization. It’s also capable of processing a wide material range from practically any manufacturer.

The system is modular (with powder handling and refreshing stations available as add-ons) and can be scaled up based on application requirements. The QLS 350 is capable of cloud connectivity and comes integrated with factory automation PLC controls.

Sinterit NILS 480

With the gap-bridging Lisa X, it’s not surprising that Sinterit offers a larger and faster polymer SLS 3D printer. Sinterit says the NILS 480 delivers industrial speed (full bed printing in 30 hours) and size (200 x 200 x 330) enabling you to print, for example, a whole shoe, housing of most electronic devices, or a whole arm orthosis.

The NILS 480 includes many of the features that made the Lisa line popular, including a wide range of material options from PA12 to PP to TPU, plus third-party powders; an open parameter environment with 32 settings to control; and intuitive software.

In essence, if you like the Lisa X but wish it was bigger and faster … here you go.

Prodways Promaker P1000 X / S

The ProMaker P1000 X SLS 3D printer by Prodways, a French 3D printer maker, is an industrial machine that brings plenty of features to the table. The build chamber has a roomy size of 300 x 300 x 360 mm, while the print speed stands at 2 liters per hour.

The P1000 X features a powerful 60W CO2 laser. It also comes with a 24 x 24 points grid thermal control system and an integrated video camera for monitoring the printing process.

Combined with the 10-zone IR heating system, the P1000 X is able to produce mechanically consistent parts from highly advanced materials. The machine also comes with open parameters that allow operators to use third-party materials. With a reasonable price tag, the P1000 X offers a good value proposition in terms of detail and performance.

Late in 2021, Prodways introduces its latest SLS machine, the ProMaker P1000 S. Billed as a more affordable version of the P1000 X, the “S” version features half the laser power and is thus a touch slower at 1.4 l/h.

3D Systems SLS 380

3D Systems has launched the new SLS 380 printer that looks to offer industrial capabilities with high repeatability and throughput. To achieve its goals, the printer uses a custom algorithm to manage eight separately calibrated heaters to control build chamber temperature.

The new printer provides a large print chamber with a good build rate and a decent level of detail. It also has a counter-rotating roller to more smoothly distribute powder across the print bed.

The SLS 380 can be combined with 3D Systems’ Material Quality Center (MQC) to control material blend and delivery. The company offers the MQC Single machines to pair with one printer, and MQC Flex that works with up to four printers simultaneously.

3D Systems also still offers the ProX SLS 6100 printer, which we featured last year. The ProX SLS 6100 provides identical chamber size and detail, but the new SLS 380 soundly beats its predecessor in print speed and temperature control.

Farsoon eForm

Chinese Farsoon Technologies’ flagship polymer technology, the 403P series of SLS printers, comes in three configurations, while its eForm SLS machine is billed as an entry level system with all the functionality and power of an industrial level system.

The eForm comes standard with an easy-to-use touch screen based UI configuration for a production environment.

The 403P machines (HS403P, SS403P, and HT403P) all have an eight-zone heater and thermal controls to ensure an even temperature and minimize risks of inaccuracies. The HT model is built for processing high-performance materials, like PA 6, at high temperatures, and features enhanced temperature shielding and thermal controls. The HS model is the – relatively speaking – budget option of the trio.

Farsoon also produces the Flight series of SLS printers, introduced in 2019 with the Flight HT403P. The Flight model features a cost-efficient fiber laser (as opposed to the CO₂ Laser in Farsoon’s other models) that is able to deliver more power and increase production speed.

Eplus3D EP-P3850

The EP-P3850 from Eplus3D — a brand of China’s Shining 3D — looks to provide high productivity at a relatively reasonable price point. With a build volume of 380 x 380 x 500 mm, it delivers one of the largest build volumes of all printers covered in this guide. The forming cylinder of the machine is detachable, which reduces standby time between print jobs and increases manufacturing and sintering efficiency.

EP-P3850 supports a good variety of materials, making the printer suitable for several applications with differing requirements. With a uniform heat control system, the printer can deliver reliably optimized mechanical properties. It also provides high powder recycling rates, which helps reach ROI faster.

EOS Formiga P 110 Velocis

Manufactured by the German industrial 3D printing pioneer, the EOS Formiga P 110 Velocis offers flexibility and cost-effective production to the manufacturing floor. With a 200 x 250 x 330 mm build envelope and layer thickness of 60 microns, this 3D printing system is ideal for manufacturing small components with complex geometries.

The P 110 features innovative temperature management and software control, which speed up the heating and recoating processes. It also has a precise laser spot with a small focus diameter that makes it possible to produce wall thicknesses of less than a half millimeter. The system is adaptable, as it’s compatible with nine polymer materials and 10 combinations of materials and layer thicknesses.

The P110 is EOS’ starter SLS machine. The company offers five more industrial SLS 3D printers with more powerful lasers and larger build volumes.

Sindoh S100

Korean 3D printer manufacturer Sindoh entered the SLS market in 2021 with the S100, complementing its line of FDM and resin printers. Unique about the S100 is its ability to print with Bluesint PA12, which isn’t just a material but also a process developed by software company Materialise to enable 3D printing with up to 100% recycled polymer powder.

Sindoh S100 offers a very large build volume, a dual-feed system and removable build system, and a fast print speed, putting it squarely in the production machine category. The machine is equipped with two lasers that each cover the full printing field. The 3D axes scanning technology makes it possible to change the laser spot size on-the-fly independently for each laser.

With a build bed temperature up to 200°C, the S100 can print with a variety of materials, including Evonik PA12, BASF Ultrasint PA11, TPU, and PP. It’s a smart choice for large-scale industrial manufacturers who need power and speed.

SLS 3D PRINTING SERVICES

You don’t have to buy an SLS 3D printing system in order to obtain SLS 3D printed parts. Another, potentially more economical and easier way is to employ a professional 3D printing service to do the work for you. This is also a great way to experiment with SLS prints before you invest in your own machine.

Third-party 3D printing services (also called service bureaus), such as FacFox, Shapeways, i.Materialise, Sculpteo, Protolabs, and many others have industrial SLS 3D printers and 3D printing experts on-site to ensure your part is printed optimally.

SLS 3D PRINTING TECH & MATERIALS

How an SLS Printer Works

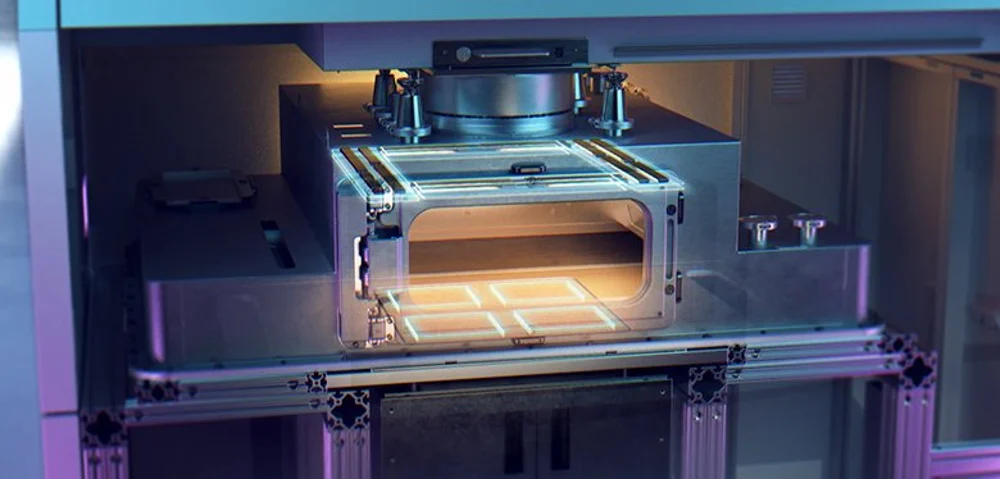

Selective Laser Sintering is a powder bed fusion technique using a high-powered laser to selectively sinter (not melt) particles of a polymer powder, fusing them together with heat and pressure in a layer-by-layer fashion until a 3D design is fabricated.

The process begins by heating the powder bin and build area to just below the polymer’s melting temperature. A recoating blade spreads a thin layer of powder across the build platform. Next, a laser (or lasers) scans the contour of the next layer and sinters the particles of the powder. To ensure that the part is completely solid, the entire cross-section of the desired component is scanned. Once a layer is complete, the build platform moves downward and the blade recoats the surface with a clean spread of powder. This process is repeated until the part or parts are complete.

Once the printing process is finished, there’s a fair amount of post-processing that follows. While removing the component, you’ll find that the solid 3D printed part is encapsulated inside the unsintered powder bed. The bin has to cool down before the part can be unearthed, and this cooling process can take hours.

After the part is removed from the build chamber, it’s cleaned with a brush, a compressed air station, or some other form of blasting technique. The loose powder left over from the print process can be collected and recycled during the next print job.

When used properly, SLS 3D printing offers a number of advantages over other digital fabrication techniques. Whether this technology is best suited for your specific prototyping or production needs depends on the application, the design of the part, and the required material.

SLS 3D Printing Materials

Can all SLS printers print with all SLS materials? Unfortunately not. Some SLS printers can print with just the two most common materials (PA 12 and PA 11) while others can print with far more. Certain printers have lasers that aren’t powerful enough for certain materials, while many manufacturers offer materials that have been customized to perform best on their printers.

Always check with your printer manufacturer which materials are approved for use, because although some materials may generally work, your print may not display the promised strength or flexibility unless it’s printed on an approved machine.

An SLS printer with an open material system can produce quality parts from a wide range of materials supplied by an equally wide range of makers, so you have some choice when shopping around. A closed-system SLS machine is approved only for use by one manufacturer’s recommended materials (usually the printer maker’s). Typically, SLS prints have a matte, rough surface that can be smoothed with post-processing.

Below is an overview of the most popular SLS 3D printing materials that are being used today (although there are others), but be sure to also check out our SLS Powder Buyer’s Guide to manufacturers, types, applications, and price.

| PA 12 | Strong parts with long-term stability and minimal water absorption, making it ideal for functional prototypes and end-use parts. Certain PA 12 materials are biocompatible and food-safe under certain conditions. |

| PA 11 | Although the mechanical properties are comparable to PA 12, PA 11 offers improved thermal and chemical resistance and higher elasticity than PA 12, plus fully isotropic behavior. PA 11 also remains stable when exposed to light, UV, and weather. PA 11 usually has a lower environmental impact as it is made from renewable raw materials derived from vegetable oil. It typically comes in a fine, black powder. |

| TPU | As a flexible and strong material, TPU powders are ideal for prototypes and end-use parts that require elasticity. This thermoplastic elastomer offers rubber-like flexibility and a high degree of functionality. TPU materials typically resist wear and tear, and have a high-quality surface finish and details. Common applications include seals, gaskets, hoses, grips, and toys. |

| PA 12 CF (Carbon Fiber-Filled Nylon) | If it’s a powder, how can it be “filled,” you may ask. In the case of these powders, filling refers to a nylon powder that’s “mixed” with additives to enhance the overall mechanical properties of the 3D printed part. Carbon fiber-filled nylon offers an exceptional weight-to-strength ratio and stiffness. However, it does tend to be highly anisotropic, which means that the material properties will vary depending on part orientation during printing. |

| PA 12 – GF (Glass-Filled Nylon) | For parts with high tensile strength and resistance to wear and temperature, glass-filled nylon has emerged as a viable option. These materials typically feature anywhere from 10% to 40% glass powder, the amount of which will impact the strength and brittleness of the final part. |

| Alumide (Aluminum-Filled Nylon) | Polyamide powder can also be mixed with aluminum powder to create an SLS 3D printing material that has a metallic appearance and a high degree of stiffness. This material can be used to produce non-porous components that are resistant to high temperatures and can be easily machined. Aluminum-filled nylon is well-suited for automotive parts, wind tunnel testing, small production runs, and more. |

| Biomedical | SLS materials for biomedical applications, including temporary implants and to replace cadaver work, are available from a variety of manufacturers, such as FibreTuff. This bone-like material has radiopacity, excellent screw retention, and sawing and cutting ability. |