Selective laser sintering (SLS) is the leading 3D printing technology for durable jigs and fixtures, lightweight components, and fast and functional spare parts, but how does it work, and which SLS 3D printers do it best?

Considering today’s supply chain disruption and climbing manufacturing and shipping costs, SLS 3D printing is an alternative that enables businesses to bring prototypes, spare parts, and even production manufacturing in-house.

Prized for its ability to create engineering-grade parts with excellent mechanical properties and fine resolution fast, SLS 3D printing is what engineers and industrial designers turn to for functional rapid prototypes and larger volumes of end-use parts. If you’re not familiar with the technology, in short, it uses lasers to fuse powdered plastic material together into 3D shapes layer by layer. It’s a category of “powder bed fusion” 3D printing. (We go deeper into the details below.)

The technology is popular for functional prototypes, spare parts, jigs and fixtures, design evaluation models, small to medium manufacturing runs, and end-use consumer products.

Industries that have taken a particular shine to SLS include:

- Automotive (jigs & fixtures, prototype cars, race car parts)

- Aerospace (prototypes, tools, air ducts)

- Medical and healthcare (prosthetics, braces)

- Consumer electronics (housings, prototypes)

- Military (replacement parts, grips)

- Heavy Industry (sand casting patterns, tooling)

SLS 3D printing is widely used today because it rivals injection molding products in terms of strength and precision. When compared to injection molding, 3D printing can create parts that injection molding can’t, such as things that have internal channels, lattice structures, and other geometrically complex features.

If you’re already familiar with SLS and are looking to buy your first SLS 3D printer or upgrade to a more powerful version, check out our buyer’s guide below to the top SLS printers on the market.

How Does an SLS Printer Work?

SLS is a powder bed fusion technique using a laser to selectively sinter (not melt) particles of a polymer powder, fusing them together with heat and pressure in a layer-by-layer fashion until a 3D design is fabricated. An SLS printer can have one or many lasers of different types (fiber laser, diode laser, CO2, etc.) and powers (10-watt, 60-watt, 100-watt).

The process begins by heating the powder bin full of powder material to just below the polymer’s melting temperature. A recoating blade spreads a thin layer of powder across the build platform. Next, a laser (or lasers) scans the contour of the layer and sinters the particles of the powder. To ensure that the part is completely solid, the entire cross-section of the desired component is scanned. Once a layer is complete, the build platform moves downward and the blade recoats the surface with a clean spread of powder. This process is repeated until the part or parts are complete.

Once the printing process is finished, there’s a fair amount of post-processing that follows. Once the build chamber has cooled, which can take hours, you’ll realize that the solid 3D printed part is encased inside the unsintered loose powder bed. To excavate your parts you’ll take the build chamber to a depowdering station. With a brush, compressed-air blower, or some other form of blasting technique you remove the loose powder and collected it for use in the next print. Add-on depowdering units cut down on the mess, but they will naturally bring up the total cost of your SLS investment.

Unlike some other 3D printing technologies, the leftover powder can be reused for the next print job. Depending on the machine, you’ll need to add 10% to 70% of fresh powder for the next print.

Benefits of SLS Technology

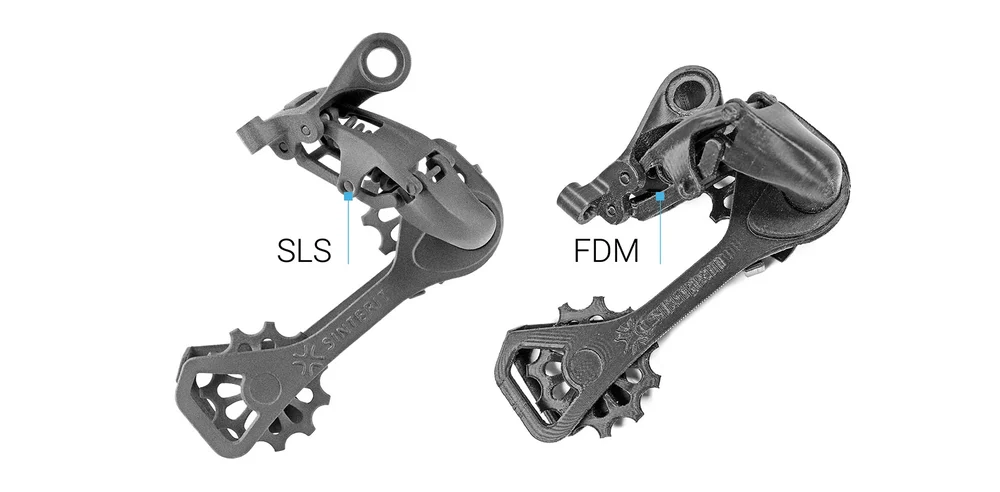

The primary reason for choosing SLS technology over 3D printers that use polymer filaments (called FDM printers) is to obtain prints with excellent and consistent mechanical performance.

Mechanical Properties

The lasers used in SLS fuse the polymer particles into a solid so that the layers are practically imperceptible. The strength and durability is on par with (or better than) injected-molded parts. SLS 3D printing with industrial-grade materials, such as carbon fiber-infused Nylon, produces parts strong enough for use in harsh conditions.

Design Opportunities

Another reason engineers are turning to SLS 3D printing is that it can produce parts with complex designs not possible or not practical with conventional manufacturing methods. Designers can consolidate complex assemblies that would normally require multiple parts into a single part. This helps alleviate weak joints and cuts down on assembly time. Parts can be created with internal lattice structures to reduce weight while retaining strength.

Fast & Productive

SLS printing is a generally fast additive manufacturing technology for functional, durable prototypes and end-use parts, but the speed depends on the printer. An industrial 12-laser SLS printer will print faster than a one-laser machine, for example. That being said, SLS is faster than layer deposition methods used in FDM.

You’re also not restricted to printing one part at a time. In fact, you can pack your build chamber to the brim with parts, which is particularly useful for printing multiple iterations at once.

Affordable

Especially for low-volume spare parts, prototypes, and custom tools, on a per-part basis, SLS 3D printing is less expensive than traditional manufacturing methods because there are no tools or molds needed.

SLS 3D printing usually comes out as the more affordable solution even after purchasing the machine and materials if your business needs small-run products, prototypes, and unique parts. Guaranteed more affordable, however, is ordering your SLS parts from an additive manufacturing service bureau.

SLS Materials

Can all SLS printers print with all SLS materials? Unfortunately not. Some SLS printers can print with just the two most common materials (PA 12 and PA 11) while others can print with far more. Certain printers have lasers that aren’t powerful enough for certain materials, while many manufacturers offer materials that have been customized to perform best on their printers.

Always check with your printer manufacturer which materials are approved for use, because although some materials may generally work, your print may not display the promised strength or flexibility unless it’s printed on an approved machine.

An SLS printer with an open material system can produce quality parts from a wide range of materials supplied by an equally wide range of makers, so you have some choice when shopping around. A closed-system SLS machine is approved only for use by one manufacturer’s recommended materials (usually the printer maker’s). Typically, SLS prints have a matte, rough surface that can be smoothed with post-processing.

Below is an overview of the most popular SLS 3D printing materials used today (although there are others), but be sure to also check out our SLS Powder Buyer’s Guide to manufacturers, types, applications, and price.

Most Popular SLS Powder Materials:

- PA 12 (Nylon)

- PA 11 (Nylon)

- TPU (Nylon)

- PA 12 CF (Carbon Fiber-Filled Nylon)

- PA 12 – GF (Glass-Filled Nylon)

- Alumide (Aluminum-Filled Nylon)

- Biomedical

- PEEK

- PEKK

- PP

SLS Printer Software & Workflow

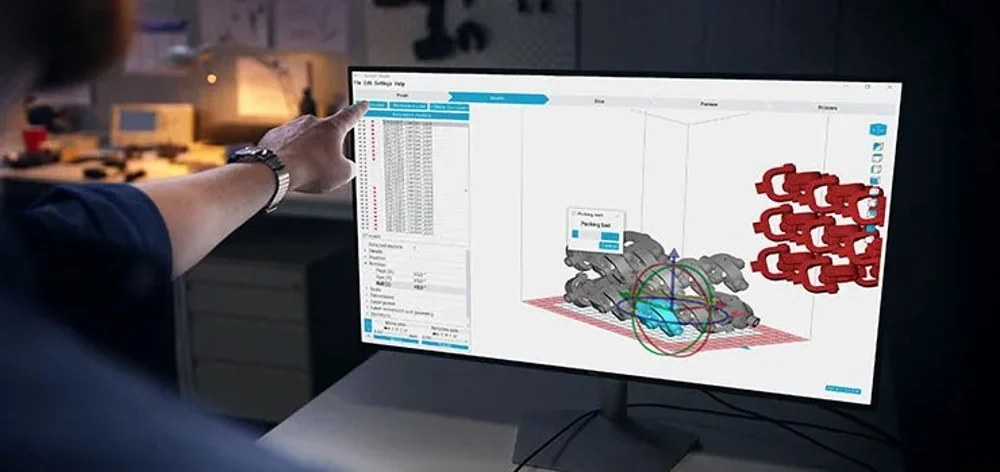

You can use any CAD software (Fusion 360, SolidWorks, Onshape, etc.) to design your part or product. Once you have a design, you’ll export it to a 3D printable file format, such as STL, OBJ, or 3MF, and upload it to your SLS printer’s software. Each SLS printer is run by proprietary software to turn your digital part file into code that your printer can follow to produce your part.

Unlike the sea of free and universal software options for FDM machines, SLS 3D printers typically come with their own software, making it an important part of your printer purchasing consideration since some have unique features.

SLS printer software is where you specify a range of printing settings, orient and arrange parts within the build chamber, and slice the digital model into individual layers for printing. The more advanced SLS machines typically have more advanced software features that enable you to fine-tune settings to get just the right results. Many also feature pre-set printing profiles that automate the entire process.

Once setup is complete, the print preparation software sends the instructions to the printer via a wireless or cable connection. The software will give you estimated print times. If you’re using more than one SLS printer, some software solutions will provide information on all of your print jobs from one dashboard, from print preparation to job status and real-time printer performance.