Nearly all metal 3D printing processes rely on metal powder. Whether used as a raw material or bound in a filament, it is the essential ingredient that enables machines to additively fabricate parts. This means the availability of metal 3D printing materials in additive manufacturing must depend almost entirely on how easily the powdered form can be fused together. Aluminum powder, for example, is more difficult to meld together than steels that are much more easily bonded, and is therefore a lot less common of a metal 3D printed material.

The most useful metal 3D printing materials offer manufacturers the greatest value-add compared to traditional manufacturing methods. Oftentimes this stems from machinability. Hard-to-machine materials like tool steels and titanium are traditionally very tough to work with, but because machinability does not equate to printability, these metals can be made on a 3D printer with minimal labor at a fixed, low cost per part.

The two main 3D Printing techniques for aluminum are Direct Metal Laser Sintering (DMLS) and Select Laser Melting (SLM). Let’s review some of the metal 3D printing materials available on FacFox, and the pros and cons that each material brings to the manufacturing process.

Aluminum

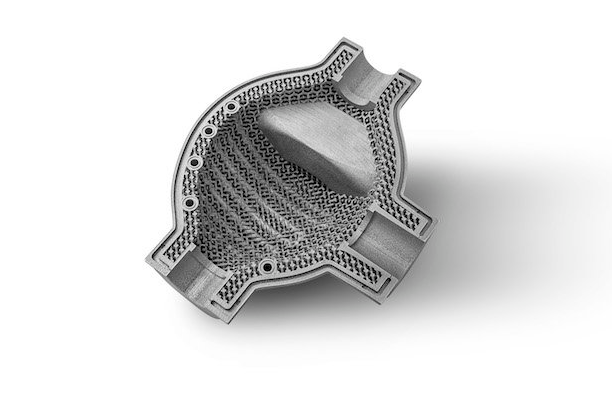

The most remarkable properties of aluminum are its low density and resistance to corrosion through the phenomenon of passivation. In contrast to traditional shiny milled aluminum, 3D printed aluminum is a bit grayer and more matte with a slightly rougher and less defined surface. Aluminum models are very strong, precise and can have feature size as small as 0.25 mm.

FacFox’s available materials:

Bronze

Bronze is a copper-based alloy and is an affordable and strong material for printing metal. In 3D Printing, bronze is typically used to produce detailed miniatures, sculptures, jewelry or preprint tests (to form-fit before producing with gold or silver).

Wax 3D Printing and lost wax casting are techniques used to build bronze designs. It can be coated with a polished PU or natural PU coating, or left natural and uncoated.

FacFox’s available materials:

Cobalt Chrome

Cobalt Chrome is characterized by high tensile strength and hardness, corrosion and wear resistance, and low ductility. Applications would include medical devices/implants, turbine engines, industrial/mechanical components, and oil and gas.

FacFox’s available materials:

Inconel

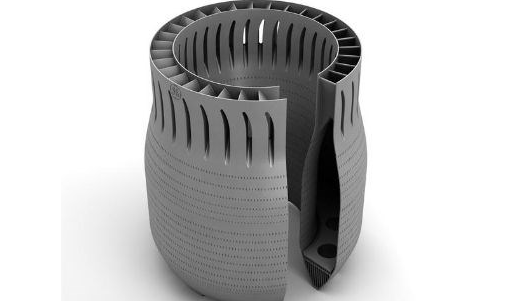

While 3D printers can be used to produce parts out of common metals such as steel, they can also fabricate parts out of superalloys that are uniquely suited for extreme environments. Inconel 625 is a strong, stiff, and very corrosion- and heat-resistant nickel-based superalloy that is often used in places like turbines and rockets.

Other types of Inconel, namely Inconel 718, don’t have the same heat resistance that Inconel 625 has. The material is traditionally wildly expensive to machine; conversely, Inconel can be purchased in powder form and 3D printed for a fraction of the cost, opening the door to affordable Inconel components.

FacFox’s available materials:

Maraging Steel

Maraging steel is a type of steel with ultra-high strength and low carbon content, which results in good machinability and chemical stability. The extended heat treatment gives this material high strength and toughness without losing malleability.

FacFox’s available materials:

Stainless Steel

Stainless steel is characterized by high strength and excellent corrosion resistance. This material is used across a vast range of industries and applications from manufacturing to assistive technology. Examples of 3D printed stainless steels include the extremely corrosion-resistant 316L and the heat treatable 17-4 PH Stainless Steel.

FacFox’s available materials:

Titanium

This metal is strong, incredibly lightweight, and heat and chemical resistant. Normally, titanium is extremely challenging to machine (contributing to its high cost), making it a great candidate for 3D printing. The most common 3D printed titanium is Titanium 64 (Ti-6Al-4V) and is used in situations when a very high strength to weight ratio is beneficial, such as aircraft.

FacFox’s available materials: