Polyvinyl alcohol, or PVA, is a water-soluble polymer, not to be confused with PVAc, or polyvinyl acetate, which is water-soluble white glue. PVA is a colorless, odorless synthetic polymer with significant biocompatibility properties. It also has low toxicity, so it can be used in health products such as contact lens solution, and it’s reasonably biodegradable.

In 3D printing, PVA is popular as a support material because it’s water-soluble. That said, it’s not the simplest material to use. That’s why, in this article, we’ll dive into exactly what makes PVA so special and how to use it before reviewing a number of great options!

Why PVA?

For 3D printing, PVA is best known as a support material used with multiple extrusion 3D printers. Normally, FDM machines create both the printed part and any support structures using the same material, as there’s only one extruder. Removing supports can be a tricky job depending on their location, not to mention the ugly marks that can be left on the part.

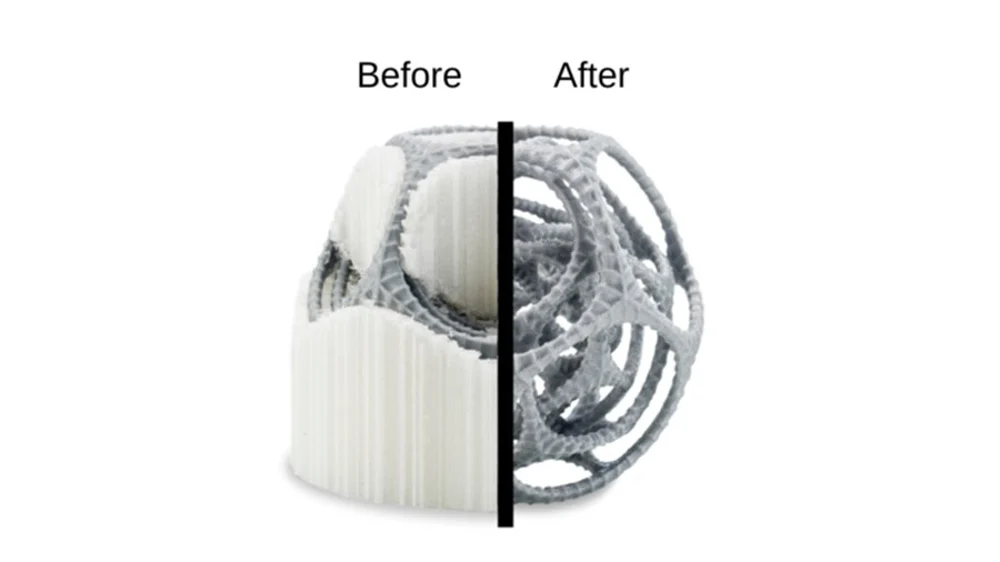

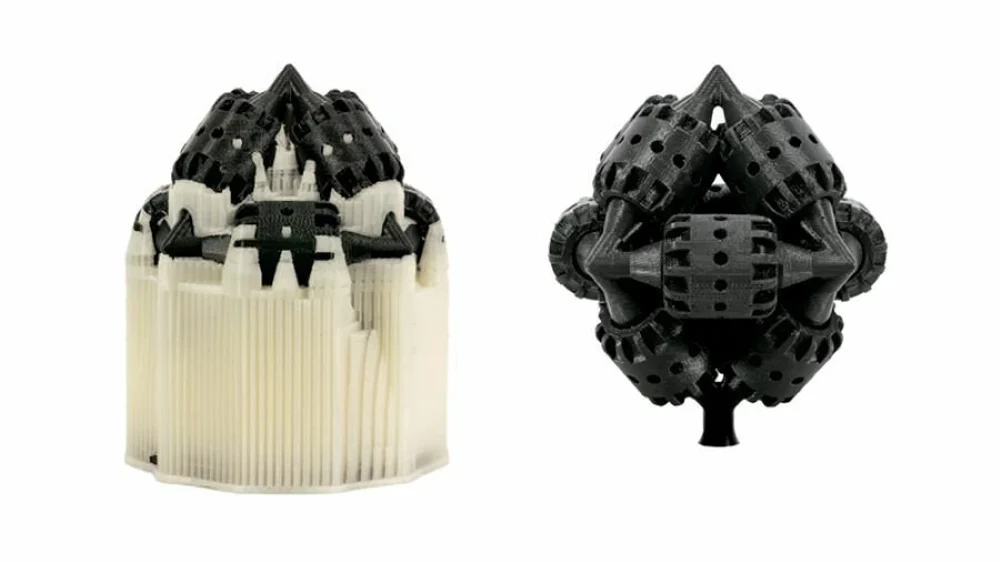

Dual-extrusion FDM printers, on the other hand, allow for the use of different materials for the part and supports, and this is where PVA comes in handy. The biggest advantage of PVA filament is that it’s water-soluble, so support structures printed with this material can be effortlessly removed by submerging the part in water for a few hours.

This method also prevents any marks from being left on the part and reduces the need for post-processing (e.g. sanding). However, it’s not as simple as it sounds: Dual extrusion can be quite tough and takes lots of calibrating to get quality 3D prints.

As a support material, PVA generally works well with PLA filaments since it requires similar printing conditions. PLA is a hydrophobic material, meaning it doesn’t “like” water, so if a PLA part is printed with PVA supports, only the supports will dissolve in water leaving the part in perfect condition.

How to Use PVA

PVA filament nozzle temperature requirements can vary widely, but they generally fall between 180 and 200 °C. Always refer to the manufacturer’s settings for optimal values, but keep in mind that high temperatures are known to rapidly degrade PVA, which can cause nozzles to clog.

For bed adhesion, a build plate temperature between 45 and 60 °C should be more than enough for both PVA and PLA. Even so, the usual tips and tricks for improving adhesion are also recommended. A part-cooling fan is required, but be careful not to overcool, as PVA can become quite brittle.

Proper filament storage is key. This hydrophilic material will absorb moisture much faster than any other filament. Make sure the spool is kept in an airtight container when not printing, and preferably store it with desiccant material, too.

Here’s a summary of the ideal settings for PVA:

- Nozzle temperature: 180-200 °C

- Bed temperature: 45-60 °C

- Part fan cooling: Up to 50%

- Soluble: In water

Now, let’s go over some of the best brands of PVA filament on the market.

MatterHackers

MatterHackers is a Californian supplier of 3D printing materials and tools. It’s known as one of the top filament manufacturers and it offers a wide range of different materials, including PVA.

The Build Series and the Pro Series are two different types of MatterHackers PVA filament. The Pro Series is considered its premium PVA material, with higher dimensional tolerance and better thermal stability.

The Pro Series PVA prints at a relatively higher nozzle temperature and dissolves naturally in regular tap water. It’s available in 1-kg spools for both 1.75- and 2.85-mm extruders.

- Nozzle temperature: 200-220 °C

- Bed temperature: 55-60 °C

- Size: 1 kg

- Diameters: 1.75 mm, 2.85 mm

- Color: Natural

- Cost: ~$114/kg

eSun

eSun is one of the most popular filament manufacturers around. Based in Shenzhen, China, they boast a huge portfolio. eSun PVA comes in 500-g spools and only in 1.75 mm. PVA is one of the more expensive filaments eSun offers, but it’s still within the market’s price range.

The company’s recommended print temperature is at the higher end (up to 220 °C). It’s a quality filament that has been praised around the world.

- Nozzle temperature: 190-220 °C

- Bed temperature: 60-80 °C

- Size: 500 g

- Diameter: 1.75 mm

- Color: Natural

- Cost: ~$80/kg

Polymaker

Polymaker is a well-known filament manufacturer that has a rather unique product portfolio. Besides a wide variety of colors available, the Shanghai-based company offers both industrial-grade and unusual materials.

Polymaker’s PVA is called PolyDissolve S1 and it was designed to work as support material for the company’s PLA, TPU, PVB, and nylon-based filaments. Like most Polymaker filament, the PVA comes in distinct 750-g spools with weight scale markings so that you can keep track of how much filament is left on the spool.

- Nozzle temperature: 215-225 °C

- Bed temperature: 25-60 °C

- Size: 750 g

- Diameters: 1.75 mm, 2.85 mm

- Color: Natural

- Cost: ~$60/kg

Ultimaker

Ultimaker released its PVA material back in 2016 specifically for its own machines, but it’s supported by any 2.85-mm FDM 3D printer.

Ultimaker PVA is somewhat different from other options available on the market for a few reasons. For starters, Ultimaker designed its PVA to work with nylon and CPE filaments. The Dutch manufacturer claims that their product is 100% biodegradable and less moisture-sensitive than other PVA filaments. Perhaps because of these peculiarities, Ultimaker PVA requires a higher nozzle temperature at around 220 °C. It’s available in 350-g or 750-g spools in Ultimaker’s standard 2.85 mm.

For further info, be sure to check out Ultimaker’s PVA guide.

- Nozzle temperature: 215-225 °C

- Bed temperature: 60 °C

- Sizes: 350 g, 750 g

- Diameter: 2.85 mm

- Color: Natural

- Cost: ~$130/kg

GizmoDorks

Another American filament manufacturer, GizmoDorks offers a PVA material specifically designed to work with PLA. They offer both 1.75- and 2.85-mm filament in 500-g spools.

The company clearly states that GizmoDorks PVA should not sit at 200 °C or more because it will degrade and clog your 3D printer’s nozzle. They also note that, should that happen, cranking up the nozzle temperature won’t help to declog it, as it can with other materials.

- Nozzle temperature: 160-190 °C

- Bed temperature: 60 °C (recommended but not required)

- Size: 500 g

- Diameters: 1.75 mm, 2.85 mm

- Color: Natural

- Cost: ~$80/kg

SainSmart

SainSmart is a professional open-hardware manufacturer that specializes in maker products, including 3D printing material. SainSmart PVA currently has the most competitive price on the market at around $33 for a 500-g spool.

It’s available in 1.75 mm and has been reported to function quite well in comparison to other brands. This may represent a good way to start tinkering with the special material that is PVA.

- Nozzle temperature: 160-180 °C

- Bed temperature: Not specified

- Size: 500 g

- Diameter: 1.75 mm

- Color: Natural

- Cost: ~$60/kg

Source: https://all3dp.com/2/pva-filament-explained-and-compared/