As designers continue to grapple with the possibility of 3D printing rubber, we tell you whether it is achievable or not and go into detail discussing alternative rubber-like 3D printing materials.

The Short and Long Answers

Is it possible to 3D print rubber? No.

Why not?

Rubber is an organic material whose properties cannot be influenced by external factors. The fact that rubber undergoes vulcanization — to improve its elasticity and strength — implies that it can never again exist in a fluid state. Vulcanization makes rubber solid and ensures it holds its shape. Any process of reheating it will cause it to burn.

Therefore, the mere fact that rubber cannot become fluid is the reason why it is impossible to 3D print rubber.

In this article, we explore rubber-like 3D printing materials that are excellent alternatives for those who want to 3D print rubber. In particular, we discuss how to print them and list some common examples. Although we’ll primarily focus on flexible filaments, we’ll also take a quick look at flexible resins.

Rubber-Like 3D Printing Materials: Flexible Filaments

Thankfully, there are rubber-like 3D printing materials that will make you feel like you are about to 3D print rubber. The most common ones are filaments made of thermoplastic elastomers (TPEs). TPEs can be used for several applications, some of which include shoe soles, flip-flops, and industrial applications like sealing rings.

Initially, printing flexible filaments caused designers a lot of trouble. That’s because these filaments were too soft, and whenever they went through a 3D printer, they didn’t print as expected.

Most extruders had the “pushing string effect”: Whenever a filament with no rigidity was pushed towards the nozzle, the filament bent or twisted because it was too soft. Thanks to the introduction of direct drive extruders, it’s now possible to print flexible filaments.

It’s important to note that flexible filament is a general give to flexible, rubber-like filaments coming from many different manufacturers. The formulas for these filaments very from one manufacturer to another.

Rubber-Like 3D Printing Materials: Flexible Resins

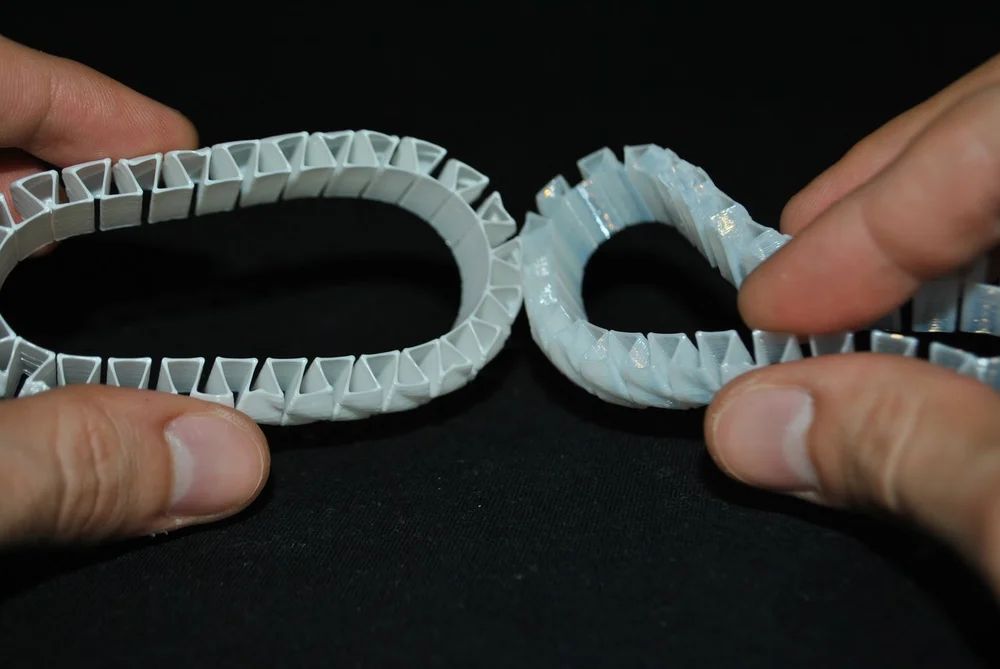

Apart from flexible filaments, flexible resin can also be used to produce rubber-like prints. Flexible resins are a perfect choice when you want to develop or prototype highly precise flexible parts like gaskets, custom grips, stamps, and wearables, or when you want to add ergonomic features to your assemblies.

When printed, flexible resin feels just like rubber and will usually compress, “bouncing back” to their original form. The main drawback is that resins are normally designed for specific printers.

Here are three examples of flexible resin:

- Formlabs Flexible Resin: Formlabs’ flexible resin is made for the Form 2 and will perform well under stress and extensive testing. It has a Shore hardness of 80A. Use it to produce bendable and compressible parts with resolutions of 50 to 100 microns.

- XYZPrinting Flexible Resin: This resin is exclusively designed for the Nobel 1.0A printer. It has been tested by professionals and is guaranteed to give you superior quality and resilience. Its flexibility makes the prints bendable when subjected to forces while solid structures printed using it are impact resistant.

- Type D Pro Flex: This epoxy-based resin by DruckWege is very flexible. It has improved properties (bending resistance and impact strength) and should be used on 3D printers with DLP/UV light sources.

How to 3D Print Flexible Filament

The Basics

Your success with flexible filaments is primarily dependent on the printer setup and how well you can calibrate your printer. You’ll need a direct drive extruder because flexible filaments tend to “escape”. Even with the smallest gap in the filament path, TPEs will push through and mess up your print.

Flexible filaments have many “demands”, but they continue to grow in popularity as designers continue to explore new techniques. Today’s filaments are used in the hobby arena to create things like grips, RC tires, robot parts, and an array of other things that require a rubber-like feel or function.

Tips & Tricks

While these filaments will bring you joy in your quest to 3D print rubber, using them can be a nightmare if you don’t follow the right procedures. With these filaments, the more elastic the material, the more difficult it is to use. To get around the difficulties posed by flexible filaments, keep the following in mind:

- Print slowly. Flexible filaments don’t do well under high speeds and need to be printed slowly. They take much longer to print compared to traditional filaments. 20–40 mm/s is a good starting point for most flexible materials, unless you have a specialized extruder.

- Find the right temperature. Start with the recommended temperature for your rubber-like filament and go up or down until you attain the desired print quality. When the environment is too hot or too cold, you’ll likely get poor results.

- The print head should not go outside the model. Ensure the extruder is within the model walls and not traveling over open air. This ensures the oozing is within the model walls. Most slicers have a setting for this.

- Check retraction. When using rubber-like filaments, retraction will bend the filament and cause jams. You should reduce it or turn it off completely.

Source: https://www.beamler.com/is-3d-printing-with-rubber-possible/