Double the possibilities with dual extruder 3D printing! Read on to learn all about dual extrusion, how to do it, and tips for pretty prints.

What Is It?

In the early days of 3D printing, FDM makers were limited to printing one material at a time because there was only one nozzle. With the development of dual extrusion in the last few years, makers now have the power to print parts composed of two or more materials.

The process of printing with dual extruders is the same as it is with “normal”, single-extruder FDM 3D printers. The only difference is that the printer automatically switches between filaments at designated times. In this article, we’ll see why dual extrusion has us seeing double!

Methods

There are actually a few different ways to 3D print with multiple filaments.

Option #1: Manual Switching of Filament

This method can be done with any single-nozzle printer and is probably familiar to most beginners: You pause the printer in the middle of an operation, take out the original filament, replace it with a different spool, and continue the print. This takes some time to do and can risk the integrity and visual quality of the final product, often due to the new filament not sticking to the old.

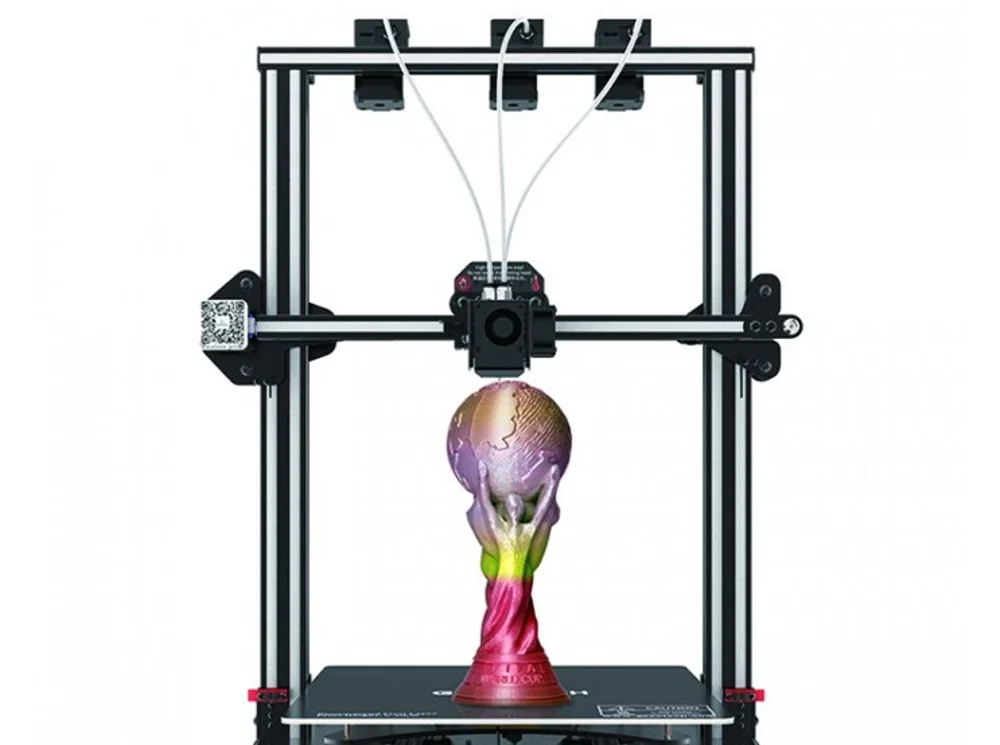

Option #2: Melting

Printers (such as the Geeetech A20T) can combine multiple materials by melting them together through the extruder at different rates to print in different colors. You’ll have to buy a new printer to do this but you’ll get to print in multiple colors and produce blending effects.

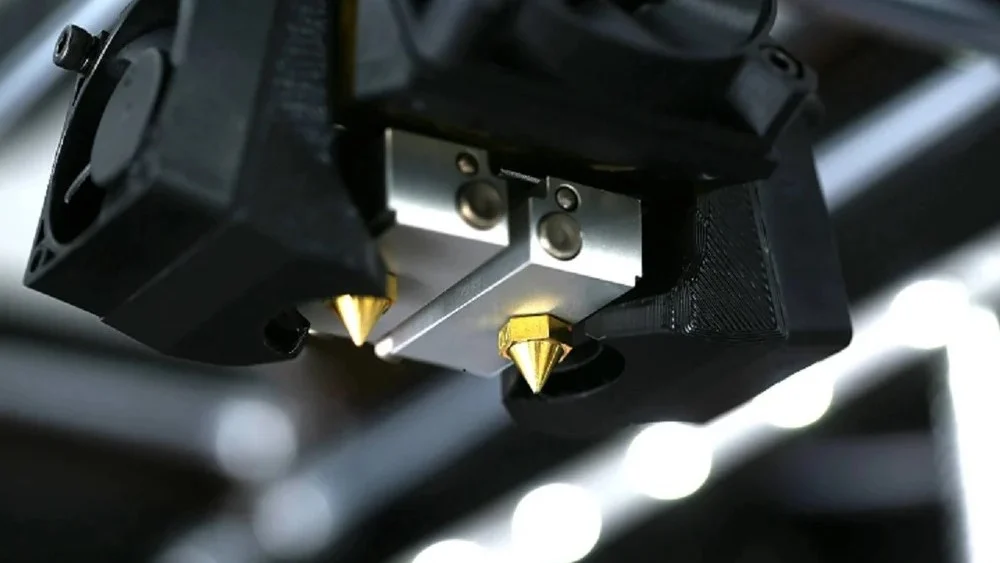

Option #3: Dual Hot End Extrusion

This involves having a 3D printer with two separate nozzles. Both can be used to print two filaments at the same time, or one can extrude filament for the model while the other prints support material. This method optimizes printing time and creates multicolor effects.

Pros & Cons

Let’s start with the good news! There are many reasons you’ll want to try out dual extrusion:

- Supports: From a functional perspective, perhaps the most significant advantage of dual extrusion is its ability to combine a standard material with an easily dissolvable support material. This is extremely useful because not only does it eliminate the need to remove supports, it also ensures that no support marks are left on the final print. The most popular dissolvable filaments used for support structures are PVA and HIPS. PVA dissolves in water, while HIPS dissolves in limonene.

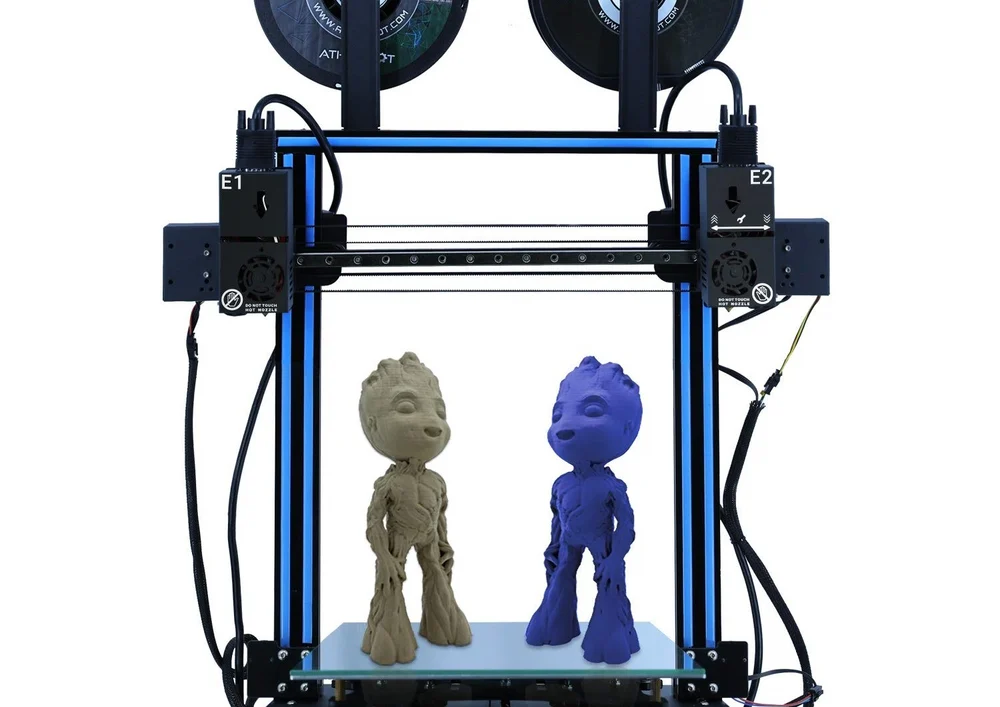

- Colors: If you’re interested in aesthetics, an obvious advantage of dual extrusion 3D printing is the ability to print in two or more different colors. This can also play a functional role if you need different regions of a print to stand out from one another. Examples might include educational models in anatomical or automotive areas. You can also create cool gradient effects for the finished product.

- Speed: By splitting up the work between two separate extruders, you can save the time that your prints take, optimizing production. Whether it’s printing a part with multiple colors, material properties, or support structures, and you won’t have to wait very long for your idea to become reality.

- Strength: Dual extrusion provides the opportunity to reinforce your main printing material with something tougher. For example, one nozzle could print the majority of a part out of PLA while the other prints only specific areas using a carbon-fiber-based filament. In this way, the final print can be much stronger.

Drawbacks

There aren’t many disadvantages to using a dual extrusion 3D printer, but cost and maintenance are ones we can’t ignore.

- High price: A dual extrusion 3D printer typically costs more than a similar single extrusion machine. There are alternatives to buying a new printer (more on that later) such as a dual extruder upgrade, which is a cheaper alternative. And, naturally, you’ll need to buy a second filament!

- More frequent maintenance: 3D printer parts don’t last forever. They require care and, at times, replacement. And don’t forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. You’re also going to have to make sure that both extruders are perfectly calibrated.

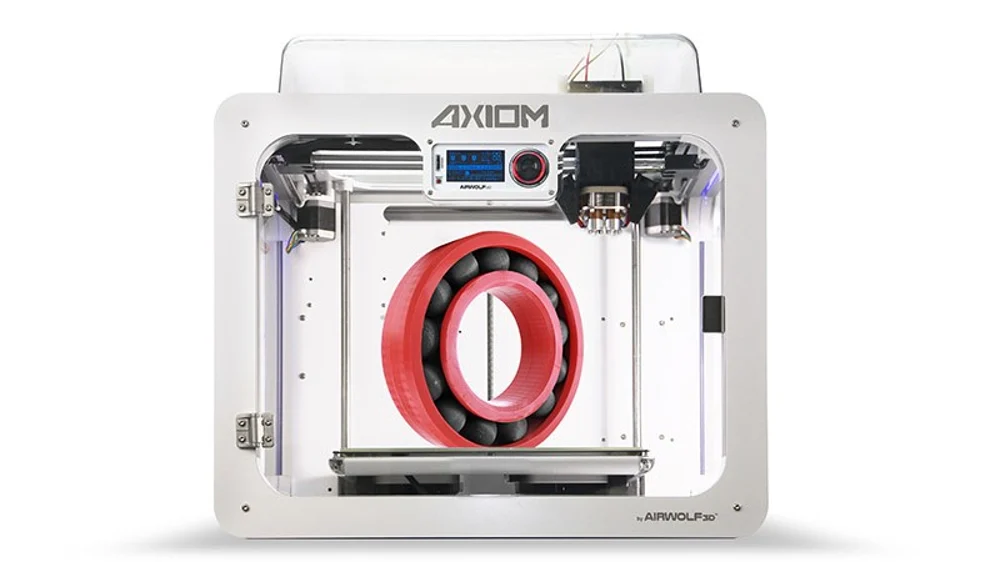

Printers

Many dual extrusion 3D printers are available on the market today. There are so many, in fact, that it may be tricky to decide which one is the best for your needs.

- Tenlog TL-D3 Pro (~$550): One of the most popular dual extrusion 3D printers of today. It has an independent dual extrusion system (IDEX) that allows multilateral and duplicate printing.

- Qidi Tech X-Pro (~$650): Another fan favorite, with a dual-nozzle system. With a smaller build volume of 230 x 150 x 150 mm, it’s a good option for smaller spaces but limiting on how big your project can be.

- Flashforge Creator Pro 2 (~$900): Another printer using an IDEX system. It has a print volume a little smaller that the Qidi, but it’s enclosed, giving you the ability to print with more filaments.

- Geeetech A10M (~$250): An option on the cheaper side. What’s especially interesting about this machine is that it only has one nozzle. Two filaments enter the print head through a “Y-splitter”, which merges the two materials and deposits a single strand. That means it has the option to print in one, the other, or a mix of the two. Naturally, the two filaments will need to have similar temperature requirements.

The Best Dual Extruder 3D Printers of 2022

Upgrades for Single Extrusion Printers

If you already own a 3D printer, and fancy the idea of 3D printing with multiple materials and colors, there are a few different accessories that make it possible to turn “normal” machines into multi-material factories. Let’s look at two of your best options:

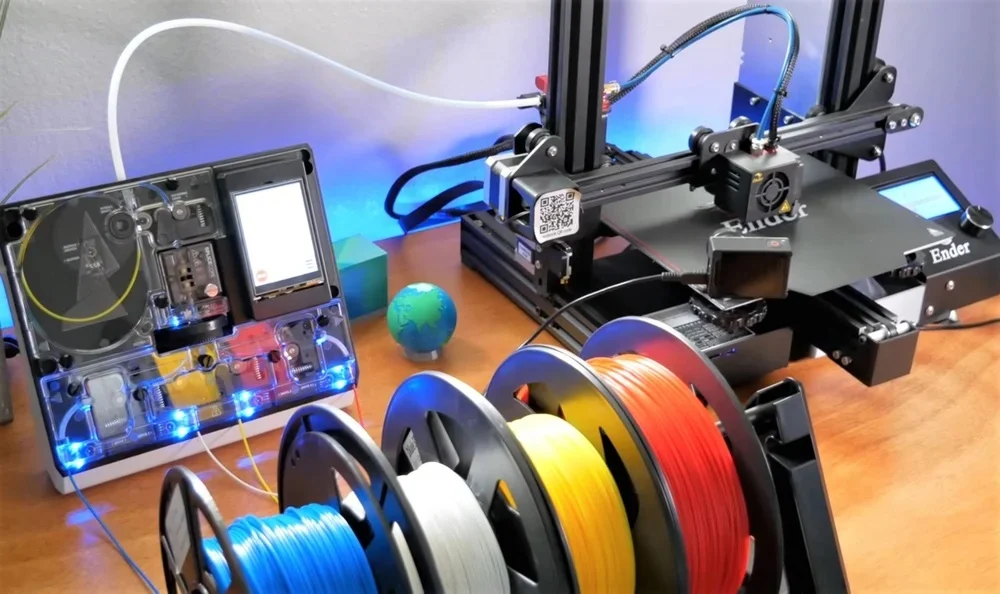

- 3D Chameleon: One of two multi-material kits designed to be added to a wide variety of open-source FDM printers. The current options include a two- and a four-color changing kit.

- Palette 2, 2S, and Pro: One of the most innovative solutions comes from a Canadian company, Mosaic Manufacturing. Their product is an add-on for 3D printers that basically creates a single filament out of multiple filaments. The device slices the filaments and fuses them into a single strand, according to your specifications and the needs of your model.

- Prusa’s Multi-Material Upgrade 2S (MMU2S): If you’re into 3D printing, you’re probably familiar with the Prusa i3 MK3S+. With the MMU2S add-on, you can print with multiple materials on your i3. How many materials, you ask? Up to five! The result is similar to the Palette, but instead of slicing and fusing, the MMU unloads and loads filament, as required.

Tips & Tricks

With more extruders, printing an amazing-looking piece can be a bit of a challenge. Here are a few tips and tricks to mitigate risk:

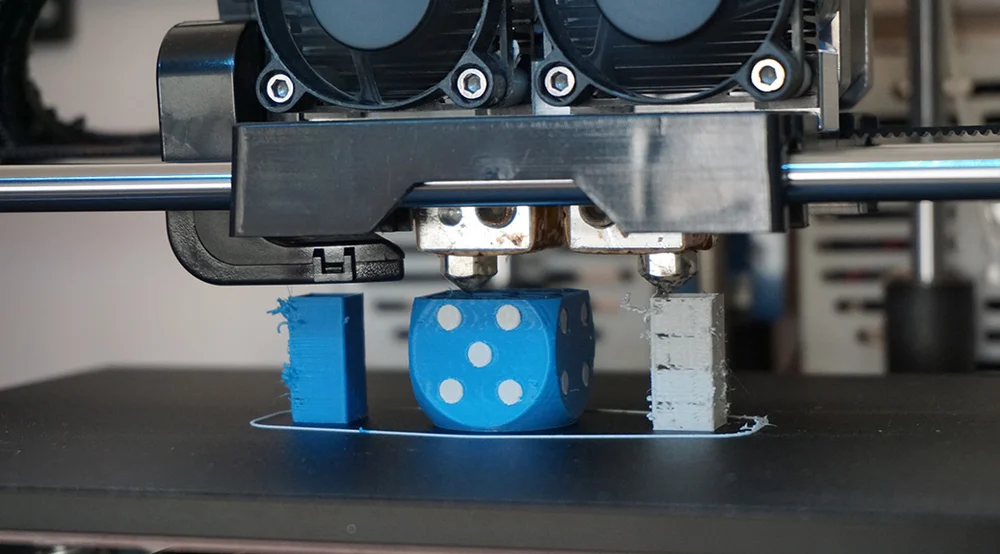

- Enable prime towers: With more extruders, there can be more oozing. To help prevent this, prime towers (also called blocks) are likely included in your slicer’s print settings. What this does is create an additional object next to the original object being printed. Every time a layer is printed, the inactive nozzle gets wiped on the tower before switching to the other nozzle.

- Ooze shield: The ooze shield is another trick to reduce oozing. A one-layer wall is created outside the perimeter of the model and catches the remaining material on the nozzle before each layer is printed. (Both the ooze and prime blocks are available options in slicing software like Cura.)

- Configure your slicer: Before printing, make sure to configure your slicer software to the correct settings. That starts with selecting the correct printer and enabling both extruders in the printer hardware settings. It might also be necessary to measure the distance between your extruders and make sure it reflected in the hardware settings.

Final Thoughts

Dual extrusion 3D printing is an exciting and useful area of additive manufacturing. Thanks to the wide variety of multi-material machines, there are many ways to take advantage of the technique.

Right now, the prices for dual extrusion 3D printers are still relatively high. However, there are a few printers that offer dual extrusion for under $600, such as the Tenlog TL-D3 Pro, which is great. If, however, buying a new machine isn’t something you’re interested in, options for add-ons exist, too like the Palette 2S.

While we’ll be watching where multi-material 3D printing will go in the next few years, one thing’s for sure: With printers like the Qidi appearing on the market, slowly dual extrusion is making its way into more affordable 3D printers.