Additive manufacturing has affected many industries, but few stand to benefit as much as the medical fields, including dentistry.

3D printing technologies thrive in an environment where our unique bodies require custom solutions. As a result, the dental industry is going through a rapid digital transformation with digital workflows bringing increased efficiency, consistently high quality, and lower costs to dental labs and practices.

Read on to discover the applications in which digital workflows are revolutionizing the dental industry, and what are the best materials for the devices.

3D Printed Surgical Guides

The first full-service solution for 3D printing FDA-compliant implant guides in your office, from scan to surgery.

Titanium Implant Bar

Implant bars make part of removable bridges. Such a bridge is regularly removed by the patient in order to clean it. After the removal of the bridge, the bar becomes visible for the patient (and eventually even for others). If the bar is anodized (e.g. to rose gold hue) it is in better harmony with the color of the interior of the mouths than a non-colored grey one. In this way, the bar better fits its environment and therefore result to an increased esthetic for the patient.

Full-Arch Surgical Guides

You can fabricate surgical guides of all kinds, including full-arch multi-site implant guides, bone reduction guides, and more.

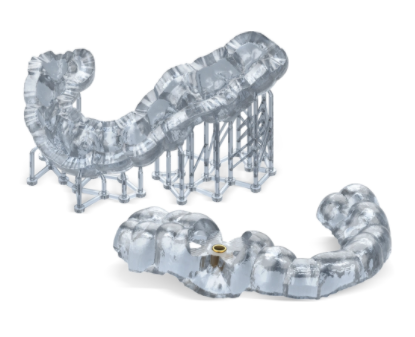

Quadrant Implant Guides

For single-unit dental implants, 3D printing provides a rapid, repeatable workflow for the production of implant guides. Simply scan, order your design with Dashboard Design, and fabricate your FDA-compliant guide.

3D Printed Dental Models

Fabricate restorative study models, removable dies, digital wax-up models, and models for thermoforming clear aligners.

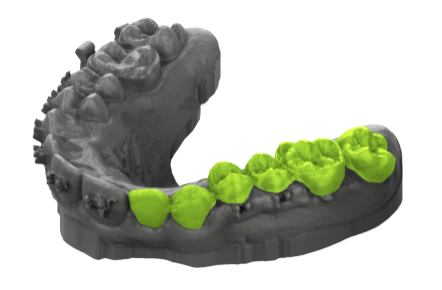

Dental Study Models

3D print dental study models and digital wax-ups to show beautiful anatomical detail. This precision allows for exceptional measurements, patient education, and laboratory collaboration. The color options allow clinicians to choose the shade that most clearly shows detail.

Models for Aligners

The full-arch orthodontic model plays an integral role in clear aligner therapy. Sequential models can be printed and used to thermoform clear aligners. In addition, complete orthodontic model can be used in conjunction with spray separators and laser soldering to fabricate orthodontic appliances.

Digital Wax Up Models

Digitally build wax up models to show patients the results they can look forward to based on your treatment plans. Gather anatomical data using your intraoral scanner, then enhance with CAD software.

Removable Dies

Useful for visual aids in dental surgery and anatomical education, we produce parts with tight tolerances so that your removable dies come out perfect with each print.

3D Printed Digital Dentures

Digital dentures can drastically reduce the cost and duration of the denture delivery process. 3D print dentures that are FDA-compliant, including biocompatible monolithic try-in dentures that can also be characterized for short-term use.

Titanium Framework of Removable Partial Denture

Metal framework removable partial dentures are the most common type of partials. They consist of a metal framework (generally CoCr) that contains artificial teeth set in acrylic resin. Patients can remove and reinsert them when required without professional help. During these operations, patients are faced with the grey color of the metal framework.

In addition, in the case of an upper partial, the grey colored framework might be visible by others. Application of 3D printed titanium frameworks anodized to the color of the palate might decrease esthetic concerns. As a result, the framework gets hidden in the mouth, in addition, it gives a more esthetic view when the partial is removed.

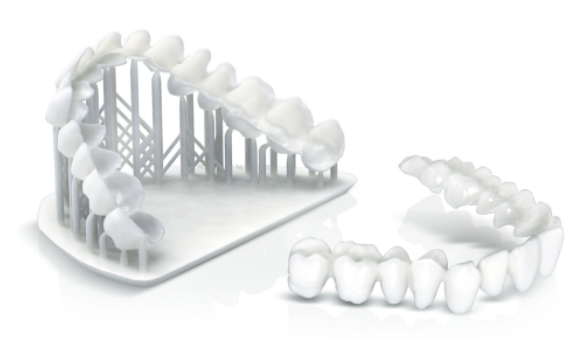

Try-in Monolithic Dentures

3D print dentures that are FDA-compliant and biocompatible, including monolithic try-ins, in just a few hours. Printed try-in dentures are perfect for checking bite registration and occlusion functionality.

Since they only cost a few dollars in materials, printed try-ins reduce wait time and cost while enabling doctors to offer patient-specific customization.

Rapid Dentures at a Low Cost

Biocompatible try-in resins can be characterized with denture stain kits to achieve aesthetically-pleasing, low-cost temporary denture options. Ideal for temporary replacements or customers who need an affordable solution. With high strength and low cost, economy dentures present a great opportunity for doctors to help patients who cannot afford traditionally-fabricated dentures.

3D Printed Clear Aligner Models

Offer clear aligners in-office to give patients the treatment they want at a price they can afford. This application allows you to set your own fees and rapidly see a return on your investment due to the significant cost savings compared to aligner labs.

Clear Retainers

Clear retainers are a common post-treatment appliance that is frequently lost or broken. Provide outstanding patient benefit by creating a replacement same- or next-day for only a few dollars in materials cost. Similar to the method used to 3D print aligners, this can provide an outstanding benefit to your patient with minimal additional cost.

Digital Bracket Removal

Deliver patient delight and reduce follow-up appointments by having a retainer premade for every bracket removal appointment. Provide a scan of the patient’s dentition with braces, and our team will digitally remove them, providing you with a model that you can print and use to thermoform a clear retainer.

3D Print Provisionals and Wax-ups

Providing temproary restorations and provisionals for esthetic work provide your patient with a great temporary solution between treatment approval and final placement. Offering next-day waxup presentations can dramatically increase case acceptance for esthetic procedures and help set patient expectations.

Temporary Restorations

3D print provisionals, crowns, and bridges for patients undergoing treatment. At only a few dollars per part to manufacture, flexibility in fees can help improve patient acceptance. And, because they can be produced in less than an hour, practices can now fabricate temporaries on the same day they’re needed.

Esthetic Wax-Ups

Final esthetic restorations such as veneers are the result of experienced craftsmen. But your patients don’t have to wait for the final product to see the results up close and in-person. With 3D printing, you can fabricate physical, beautiful wax-ups for patient presentation in a matter of hours.

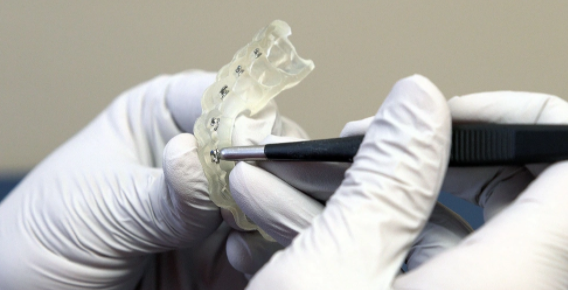

3D Printed Indirect Bonding Trays

Shorten the length of bracket placement appointments, decreasing chair time and increasing patient satisfaction. 3D print indirect bonding trays to load an entire arch of brackets into the tray, then quickly transfer those brackets onto the patient’s teeth.

Allow for the speedy placement of a full-arch of brackets. The pre-printed apparatus also means that each bracket gets placed exactly where it should be, removing the guesswork and improving placement accuracy.

3D Printed Occlusal Guards and Splints

For a comfortable fit that provides both flexure and excellent resistance to wear, we can 3D print splints and occlusal guards with the innovative KeySplint Soft resin. This material becomes flexible when heated, meaning it conforms perfectly to your patient’s anatomy. Despite its flexibility, it produces long-lasting splints and nightguards that can be easily polished clear.

3D Printing Dental Crowns and Bridges

Temporary Restorations

With 3D printing in your office, you can provide aesthetic temporary restorations to more patients. High-strength custom temporaries will delight your patients by giving them an above-and-beyond experience at your practice.

Definitive Restorations

With full certification for definitive restorative applications, we can help you deliver an unprecedented patient experience. Printed crowns can be characterized just like traditional restorations and secured using standard self-adhesive cement.

The requirements for dental 3D printing materials

As dentistry is a special and high-demand industry, the materials should comply with a variety of safety and quality standards in different jurisdictions.

The resin and metal alloy materials should be biocompatible and evaluated in accordance with FDA, ISO, USP, and EU MDR standards.

Titanium (Ti6Al4V · TC4)

Cobalt Chrome (CoCrMoW · SP2)

Like titanium, cobalt chrome has very high corrosion resistance and excellent biocompatibility. It offers additional strength and hardness over titanium and is commonly used for replacement teeth in addition to heavy-use replacement joints like knees, hips, and shoulders. Cobalt chrome is also 3D printed using DMLS.

Conclusion

Dental manufacturing applications need precision along with speed. 3D Printing is revolutionizing the dental industry and is having impacts on all aspects of dental care. Therefore, it is indispensable to make use of 3D printing materials and hardware for attaining better results and accuracy as we further progress in the digital age of dentistry.