Even a perfectly designed injection-molded part can fail if manufactured from the wrong material, and with literally hundreds of thermoplastics and elastomers to choose from, it’s often difficult to know which ones will meet the application’s requirements. This is why a host of factors such as mechanical strength, chemical and ultraviolet light resistance, lubricity, wear resistance, and more must be carefully considered when selecting materials for injection molding.

| 3 MATERIAL INTERACTION QUESTIONS TO ASK |

|---|

| Friction & Wear Have you considered how your design is impacted by the friction and wear that occurs between surfaces interacting with one another?Compatibility Are your plastic and elastomeric components chemically compatible? Adhesion |

This situation becomes even more challenging with over-molded parts, where designers must not only adhere more closely to established molding principles, but also make certain that the chemical and physical bonds between their chosen materials are both strong and permanent. This tip discusses three key areas—material compatibility, adhesion, and tribology—that designers should be knowledgeable about when designing molded parts.

Friction and Wear

Let’s start with a term not often heard on the manufacturing floor. Tribology is the study of friction and wear that occurs between two surfaces moving relative to one another. It concerns the interaction between the interlocking clips and tabs of a snap-fit container, for example. An engineer looking at the tribology of parts would probably care less about the chemical and mechanical bonds needed to overmold a handle for a power tool (because they don’t slide against one another, assuming the design is sound), and more about the feel and grippability of the overmolding material itself.

In the snap-fit clip example, a wear-resistant polymer such as HDPE might be a good choice, although a relatively lubricious material like acetal could also be a candidate. Both materials have their own unique virtues that should be carefully weighed early in the development process. Yet the product design itself can also play a huge tribological factor. Surfaces that interact with one another should be smooth, lest the miniature peaks and valleys found on rougher surfaces catch and break away with repeated use.

The method used to manufacture the part also plays a role. In the clip example, which can easily extend to any number of plastic parts with mating or interlocking surfaces, a machined finish is different than a 3D-printed one, as is an injection-molded surface (and is likely to be smoother than either). The message here is that these and other part characteristics should be carefully analyzed and tested before traveling too far down the design road when part interaction is a design concern.

Here’s another example. Metal inserts are a popular option at FacFox. Whether you need a bronze bushing in an injection-molded fan blade, a stainless steel sleeve in a plastic pulley, or a threaded brass nut in an equipment knob, placing these and other inserts in injection-molded parts is no big deal. There’s little concern over material compatibility, and the biggest obstacle the designer will face is making sure that a good mechanical bond is created when the plastic is injected over and around the insert. That said, bronze and brass make for good, low-cost bearing surfaces, but are more prone to wear than an actual ball-bearing. Ask yourself this: Does your design meet the product’s long-term requirements? A good understanding of tribology will help resolve this and other important questions.

Material Compatibility

Few would argue that overmolding is one of the coolest things to happen to plastic parts since quick-turn injection molds. It’s a great option anywhere a soft or user-friendly material is needed atop a structural core—an instrument handle, perhaps, or handheld electronics housing—or where multiple colors are desired for aesthetic reasons. There’s plenty of information online about designing for the overmolding process, discussing the need for a sound mechanical bond as well as chemical compatibility between the two adjoining materials.

The good news is that a host of chemically compatible materials are available. For instance, FacFox offers Santoprene 101-87 TPV, a hard, black thermoplastic vulcanizate that forms a strong chemical bond with polypropylene, making it suitable for a variety of automotive and consumer applications. There’s TPC Hytrel 3078, a heat- and chemical-resistant thermoplastic elastomer that mates up just fine with ABS, polycarbonate, and more. And TPE-Versaflex OM 1040X-1 is frequently used for medical parts—it, too, bonds well with ABS and polycarbonate. Nylon, on the other hand, is among the more difficult substrates for overmolding due to its moisture-absorbing tendencies, though it remains a popular material across a range of applications.

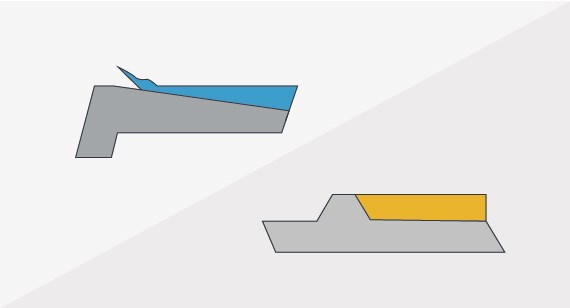

Adhesion

There’s more to it than that, however. Part design can have a significant effect on the adhesion level of overmolded parts. The transition between substrate and overlay should be abrupt to avoid feathering or thinning—consider using a groove or shoulder to create a clear cutoff point. Curling and potential tear points can be eliminated by placing the shutoff in a location that creates a hard stop for soft, squishy, and very flowable TPE. Use too thin of an overlay—say anything less than 1/16-inch thick—and the material may cool too quickly for proper adhesion. Long length-to-thickness ratios can cause similar problems.

Also, be aware of the two materials’ unique thermal characteristics when overmolding. You might select liquid silicone rubber (LSR) for its excellent heat and chemical resistance, low-temperature flexibility, and inherent lubricity, but keep in mind that LSR cures at 300 to 400 degrees Fahrenheit, a temperature too high for ABS, polyethylene, polypropylene, and a number of other thermoplastics to survive. Venting is also important, as burning, insufficient adhesion, and incomplete cavity filling—short shots—can occur in an improperly vented mold.

It’s easy enough to check the compatibility chart online, but if you prefer to supply your own material, it might be best to check with your plastics supplier for molding and application advice. This is especially true if you’re using a custom polymer mix, which an increasing number of FacFox’ customers do. Be aware that colorants can create adhesion problems, as can high amounts of additives such as metal and glass. Our advice is to always run a few sample parts and test thoroughly before pulling the trigger on higher volumes.

Adhere to Design Guidelines

The list of examples is long, the possible polymer combinations nearly endless. That’s why it’s important to check with someone knowledgeable on the vagaries of polymer adhesion and chemical compatibility early in the design process, to verify that A) your chosen materials will play nice together, B) the part or overmolded assembly is moldable given your current design, and C) that the materials are tribologically sound—that is, they are slippery enough, wear-resistant enough, or sticky enough for the product’s purposes.

This is one time when sticking to FacFox’ guidelines is especially important. Using a plastic that’s high in additives might help you achieve your product requirements, but it might also mean spending more time on the product design; the “sweet spot” of moldability becomes smaller and smaller as plastic additives increase, and only gets more challenging with high complexity parts.

Scared? Don’t be. All of these situations are quite manageable, it just takes a little more attention during the design process and possibly a second look at your material selection. And when in doubt, give FacFox a call, even if you’re just kicking the tires at this point. Between our knowledgeable staff, automated quoting process, and free moldability analysis, even the most chemically challenging materials are easy to master.

As always, if you have questions or concerns, feel free to contact one of FacFox’ applications engineers at info@facfox.com to discuss options.