Food is definitely the most delicious application of 3D printing. Let’s explore the exciting movement of 3D printed food!

Generally speaking, 3D printed food is a meal prepared through an automated additive process. While this definition can be quite abstract (and it is), think of those pizza vending machines that surfaced back in 2015. The dough is prepared, extruded, topped with tomato sauce and cheese, and finally sent to the oven – all within the same machine. This process, in a way, can be considered a primitive 3D printing food process.

Fast forward to 2021 and we have exclusive 3D printing restaurants and dozens of food printers available on the market. This rapid growth in both technology and public interest has led many to claim that, soon enough, every household kitchen will be equipped with its own food 3D printer.

In this article, we’ll explore the entire 3D printed food industry: the processes, foods, possibilities, and current challenges. Hope you’re hungry!

Which Foods Can Be 3D Printed?

In reality, 3D printed food is still in its infancy and has a long way to go before seeing a broader adoption from professionals and consumers. However, this doesn’t stop us from marveling at these fascinating machines and their intriguing edible designs.

The foods that can be 3D printed are limited to the processes available (as we’ll see in the next section). Material extrusion is by far the most common process for 3D printing food, and, similar to FDM printing, requires paste-like inputs like purées, mousses, and other viscous foods such as chocolate ganache.

At first, it might feel a bit restricted in terms of options, but think of all the possible combinations between doughs, mashes, cheeses, frostings, and even raw meats.

How Does It Work?

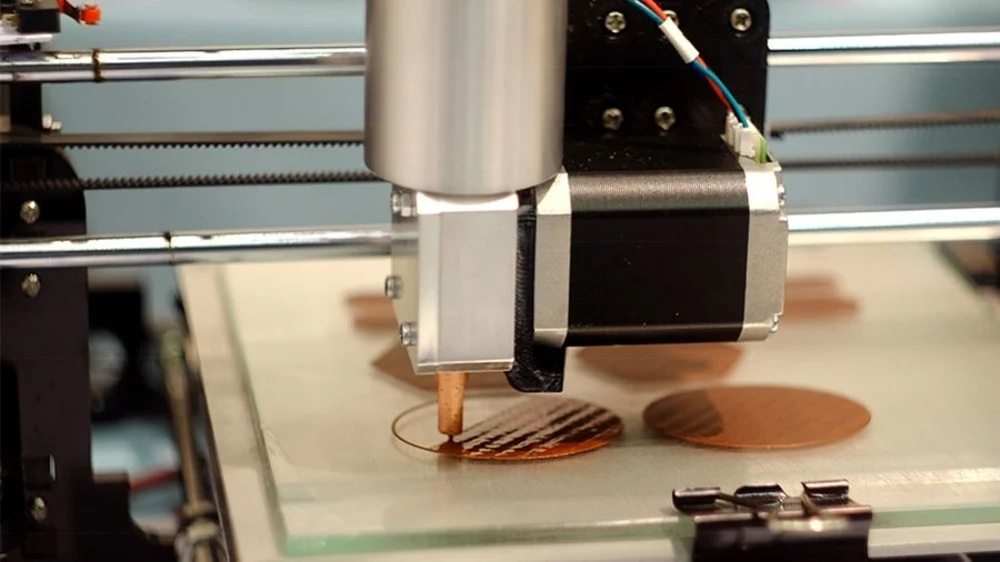

Mostly, 3D printing food works much like printing filament with a regular FDM 3D printer, in the sense that a viscous material is deposited onto a surface to create a final object. While there have been studies with other additive processes like binder jetting and SLS with powdered foodstuffs, it’s still debatable whether these processes are viable for food printing or not.

Meanwhile, there’s a growing market of both professional and prosumer FDM-like food printing machines, as we’ll see later in this article. The process is roughly the same for most of these machines: the raw material is fed into a syringe-like container and extruded as the nozzle is moved around to trace shapes and form 2D layers one at a time.

Do Food 3D Printers Cook the Food?

Food 3D printers are mostly suited for architecting intricate shapes and designs, not actually cooking the ingredients. Usually, the edibles are either ready for consumption or will be cooked in an external oven (or grill) once the 3D printing process is finished.

There are some exceptions, of course. The PancakeBot is a machine that only makes pancakes, by extruding the batter directly onto a hotplate. It still requires someone to flip it, but everything else is done with the same equipment.

Where Is It Used?

Today, food 3D printers are mostly used for gourmet dining, be it in molecular kitchens or fancy bakeries. This technology is still not scalable, as it requires more time and development to mature. That doesn’t stop pioneers and innovators from using it, though.

Back in 2016, two world-class chefs created a new restaurant concept in London, named Food Ink. The idea at first was just to serve 3D-printed dishes, but eventually, they went as far as having only 3D printed furniture in the restaurant. Food Ink is a traveling restaurant currently on a world tour.

But not only in fine dining can you find 3D printed food. Bakers have made headlines for printing edible wedding cake decorations, and for all you pizza lovers, 3D printed pizzas have been in the works for some time and will surely be a reality sooner rather than later. More recently, plant-based meat is being 3D printed as a way to mimic the texture from the real thing, while a German company used 3D printers to create accessible meals for seniors who struggle to process solid foods.

So, Where Can I Find It?

Honestly, it can be a bit difficult to find 3D printed food even in metropolitan areas. Your best chances would be in 3D printing events or culinary conventions such as 3D food printing conferences, as this new technology has not achieved much commercial success. Yet.

Pros & Cons

At its simplest, 3D printed food is nothing more than typical edible ingredients processed in such a way that they can be extruded through a nozzle onto a surface. Perhaps the main difference with respect to conventional meals is the final presentation: 3D printing allows the creation of complex, intricate shapes and geometries that are either impossible to reproduce manually or that would require an extraordinary amount of time.

Benefits

It’s completely safe to consume 3D printed foodstuffs as long as they’ve been prepared in an appropriate machine in a clean environment (as with any other kitchen). In addition to creating amazing-looking meals, there are other positives to 3D printing food:

- Personalizing meals: In terms of controlling the diversity and amount of nutrients, vitamins, and calories per meal, 3D printing food allows for precision. This could be extremely important in hospitals where restricted diets are more common, and offers the potential for easy patient customization.

- Unconventional food consumption: When you process nutritious plants and protein-rich insects in a semi-liquid state, these foods could be presented in a more attractive way and thus incentivize their consumption. In the future, even synthetic food might be 3D printed. Who knows!

- Easy reproducibility: Sharing recipes could be as simple as transferring a digital file over the internet. All that would be required is the same raw materials, printing settings, and compatible printing equipment.

Drawbacks

With all these interesting advantages that 3D printing food brings, we’d be remiss not to mention that it does have some downsides. Although times can vary based on the printer and the food being printed, according to Choc Edge, a food 3D printer manufacturer, a very simple six-layer design can take 7 minutes to print, while more detailed 3D models take more than 45 minutes each. It might not sound like much a first, but at these speeds, the whole enterprise lacks scalability.

The cost of equipment and consumables also presents barriers as we’ll see next, not to mention the time spent on training. Furthermore, the edibles used in these machines either require pre-cooking or pre-processing to achieve the consistency required for extrusion. Therefore, the expected reproducibility and reliability for these machines depend heavily on the proper preparation of those materials.

Source: https://all3dp.com/2/3d-printed-food-3d-printing-food/