If you do it in your garage, it’s “3D printing”. If it’s used to build a car, it’s “additive manufacturing”? Where’s line between these two terms? Let’s see if we can’t find it.

Two Terms, Two Meanings?

Are “3D printing” and “additive manufacturing” (AM) the same thing? In general, we know that terms stretch over time to include more than just their default meanings. Most of us carry digital entertainment supercomputers around in our pockets, and call them “phones”.

Whatever the name, new ways of fabricating directly from bytes to stuff are radically changing the what, where, how, and when of making objects. What roles, then, do the two terms “additive manufacturing” and “3D printing” play in describing new ways of making?

Consulting Experts

Let’s start by considering what the experts have to say:

- The standards organization ASTM International equates the two terms in their definition: “Additive manufacturing, also known as 3D printing, uses computer-aided design to build objects layer by layer.”

- Wikipedia says, “today, the precision, repeatability, and material range have increased to the point that 3D printing is considered as an industrial production technology, with the name of additive manufacturing.”

- Author Dave Turbide puts it simply, suggesting that additive manufacturing is “the industrial version of 3D printing”.

Putting these and other definition together, we can begin to see what the difference might be between 3D printing and additive manufacturing.

3D Printing: It’s All About the Printer

When MIT invented binder jet printing in the 1980s, they wrote “three dimensional printing is a process under development at MIT for the rapid and flexible production of prototype parts, end-use parts, and tools directly from a CAD model.”

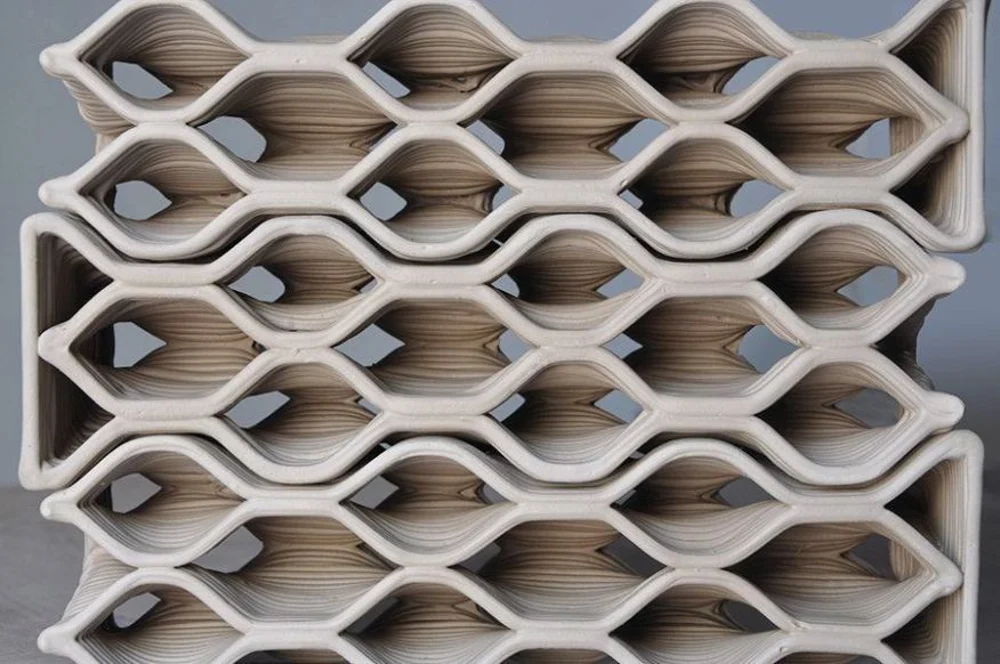

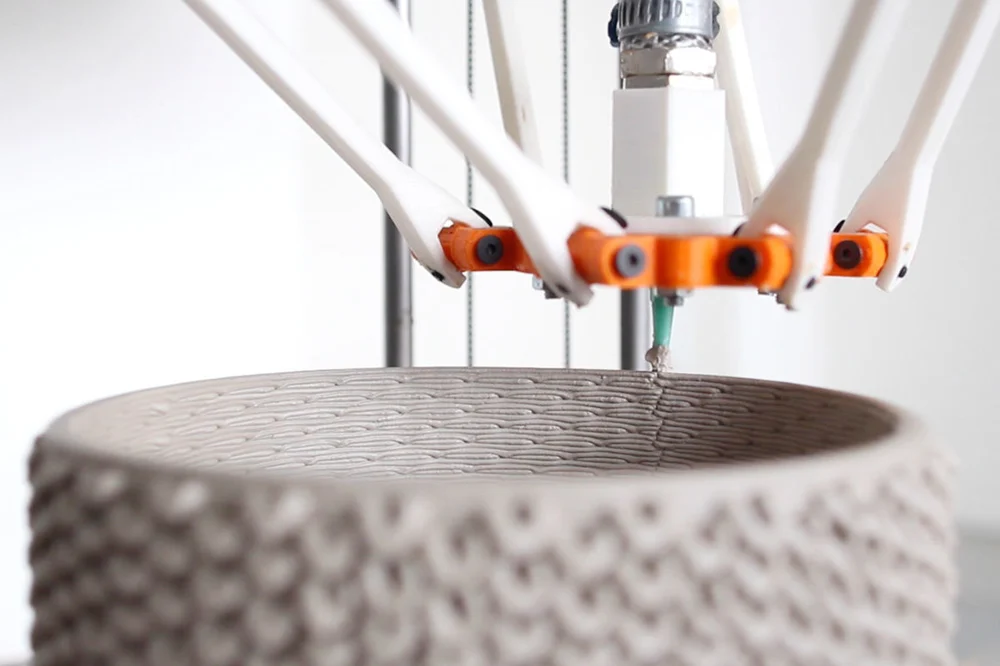

Today our concept of “3D printing” is much broader, but the term is often associated with filament-based plastic printers, which are the pride and joy of many a hobbyist and self-described maker. But there are also binder jet printers, laser metal 3D printers, as well as glass and clay 3D printers.

Whatever the kind of printer, the term “3D printing” looks to the printer itself, and the full range of technologies that can build an object from a CAD file. How big of a part can it print? In what materials, and and how fast? Is the printer filament, resin, or powder-based? Thinking about 3D printers and “3D printing” brings all of these questions to mind.

Additive Manufacturing: A Bytes-to-Parts Supply Chain

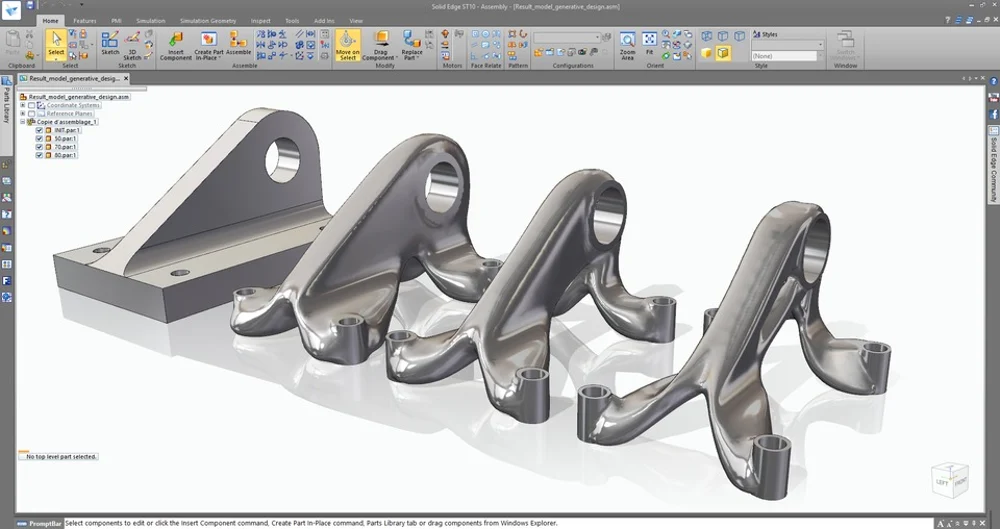

“Additive manufacturing” (AM) is a big picture term more at home in the boardroom than the factory floor or garage. Naturally, AM separates itself from older, subtractive technologies like milling. Otherwise, the term is less about the 3D printer itself, and more about the manufacturing process transformed by 3D printing.

What is that transformation? AM changes the way we think about inventory and supply chain, taking parts from the point of manufacture to the point of use.

AM is flexible in the time it takes to load a file, from anywhere in the world. It enables customized parts, in volume, and involves stocking raw materials like filament and printing spare parts on demand.

Additive technologies enable designs that are not possible with subtractive manufacturing techniques, like hollow designs with infill or topological optimized designs. In that way, AM is about taking all of the design and production possibilities of 3D printing and applying them to engineering, manufacturing, and supply chains.

Adding It All Up

In the narrowest sense, the two terms refer to the same thing: additively making parts directly from CAD. They are synonyms, both useful, co-existing in largely overlapping domains.

For now, “3D printing” is a term for the shop and factory floor, while “additive manufacturing” is for the enterprise and supply chain.

This new way of making is a spectrum, from the tiny focus of a laser or the .25-mm extrusion of a plastic to concrete-extruding house-sized 3D printers and global manufacturing processes enabled by communications and local 3D printing. One end of that spectrum is “3D printing”. The other, “additive manufacturing”. Somewhere in the middle they meet.

Source: https://monroeengineering.com/blog/3d-printing-vs-additive-manufacturing-whats-the-difference/