3D printing technology has evolved significantly, enabling the creation of objects with incredible strength and durability. Whether you’re an engineer, designer, or hobbyist, selecting the right material is crucial for the success of your project. Here are the ten strongest materials commonly used in 3D printing, known for their robustness and versatility.

1. Polycarbonate (PC)

Polycarbonate is one of the most durable 3D printing materials available. Known for its high impact resistance and strength, it is ideal for producing parts that need to withstand significant stress and strain. Polycarbonate’s ability to endure high temperatures and its clear, transparent finish make it a popular choice for applications like mechanical parts, automotive components, electronic housings, and even protective gear.

2. Nylon (Polyamide)

Nylon is a popular choice for its excellent balance of strength, flexibility, and durability. It’s highly resistant to wear and abrasion, making it suitable for functional prototypes, gears, and living hinges. Nylon’s flexibility also makes it ideal for parts requiring high-impact resistance. With its low friction coefficient, nylon is also used in creating bearings, bushings, and other moving parts.

3. Carbon Fiber Reinforced Filaments

Carbon fiber-reinforced filaments combine the strength of carbon fiber with the versatility of standard 3D printing materials like PLA or nylon. These composites offer high stiffness, low weight, and excellent dimensional stability, perfect for aerospace, automotive, and industrial applications. The inclusion of carbon fibers significantly enhances the mechanical properties, making these filaments suitable for parts that must endure substantial mechanical stress.

4. Polyether Ether Ketone (PEEK)

PEEK is a high-performance thermoplastic known for its exceptional mechanical properties, including high tensile strength, heat resistance, and chemical resistance. It can withstand continuous use in hot water or steam without any significant degradation, making it ideal for demanding environments such as aerospace, medical, and oil and gas industries. PEEK is often used in manufacturing components that require high precision and reliability, such as bearings, pumps, and medical implants.

5. Ultem (PEI)

Ultem, or Polyetherimide (PEI), is a high-strength thermoplastic with excellent thermal and chemical resistance. It is commonly used in the aerospace, automotive, and medical fields for parts that require high heat resistance and strength. Ultem’s ability to maintain its properties at elevated temperatures and its flame-retardant characteristics make it ideal for electrical connectors, insulators, and high-temperature applications.

6. Polyethylene Terephthalate Glycol (PETG)

PETG is a strong and durable material that combines the ease of printing of PLA with the strength and chemical resistance of ABS. It’s ideal for creating parts that require durability and flexibility, such as mechanical components and outdoor equipment. PETG’s transparency and resistance to UV and impact make it a popular choice for packaging, medical devices, and signage.

7. Acrylonitrile Butadiene Styrene (ABS)

ABS is a widely used thermoplastic known for its strength, toughness, and impact resistance. It is commonly used in automotive parts, electronic housings, and toys like LEGO bricks. ABS can withstand higher temperatures and is relatively easy to post-process. It can be sanded, painted, or glued, making it versatile for a wide range of applications.

8. High-Performance Polyamide (HP PA)

HP PA, also known as PA 11 or PA 12, is a robust material with excellent mechanical properties, including high impact resistance, flexibility, and chemical resistance. It is suitable for creating functional prototypes, end-use parts, and complex geometries. Its ability to withstand harsh environmental conditions makes it ideal for outdoor and industrial applications.

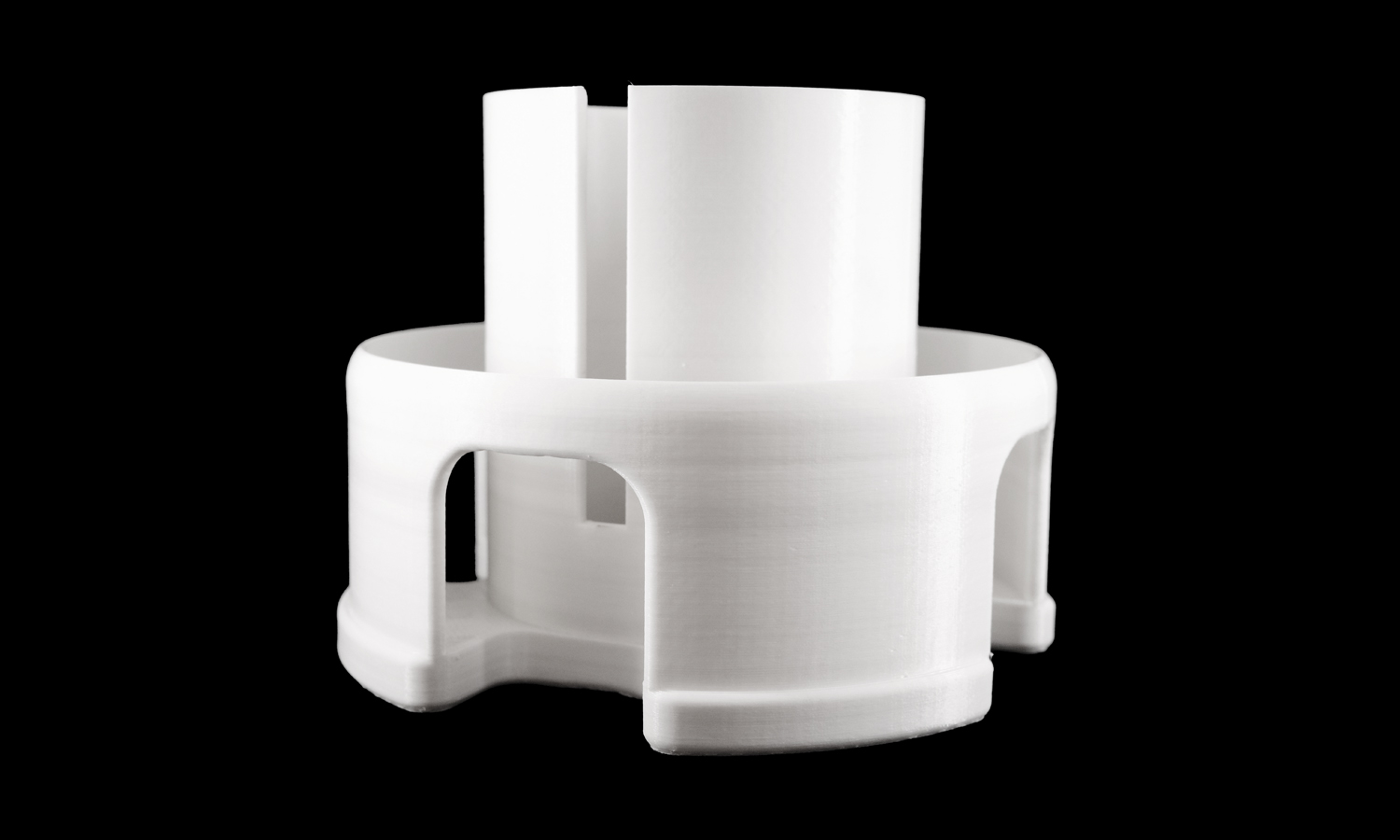

9. Polypropylene (PP)

Polypropylene is known for its excellent chemical resistance, fatigue resistance, and elasticity. It is ideal for producing living hinges, containers, and automotive parts that require high durability and flexibility. Polypropylene’s lightweight nature and ability to endure repeated flexing without breaking make it suitable for a variety of consumer and industrial products.

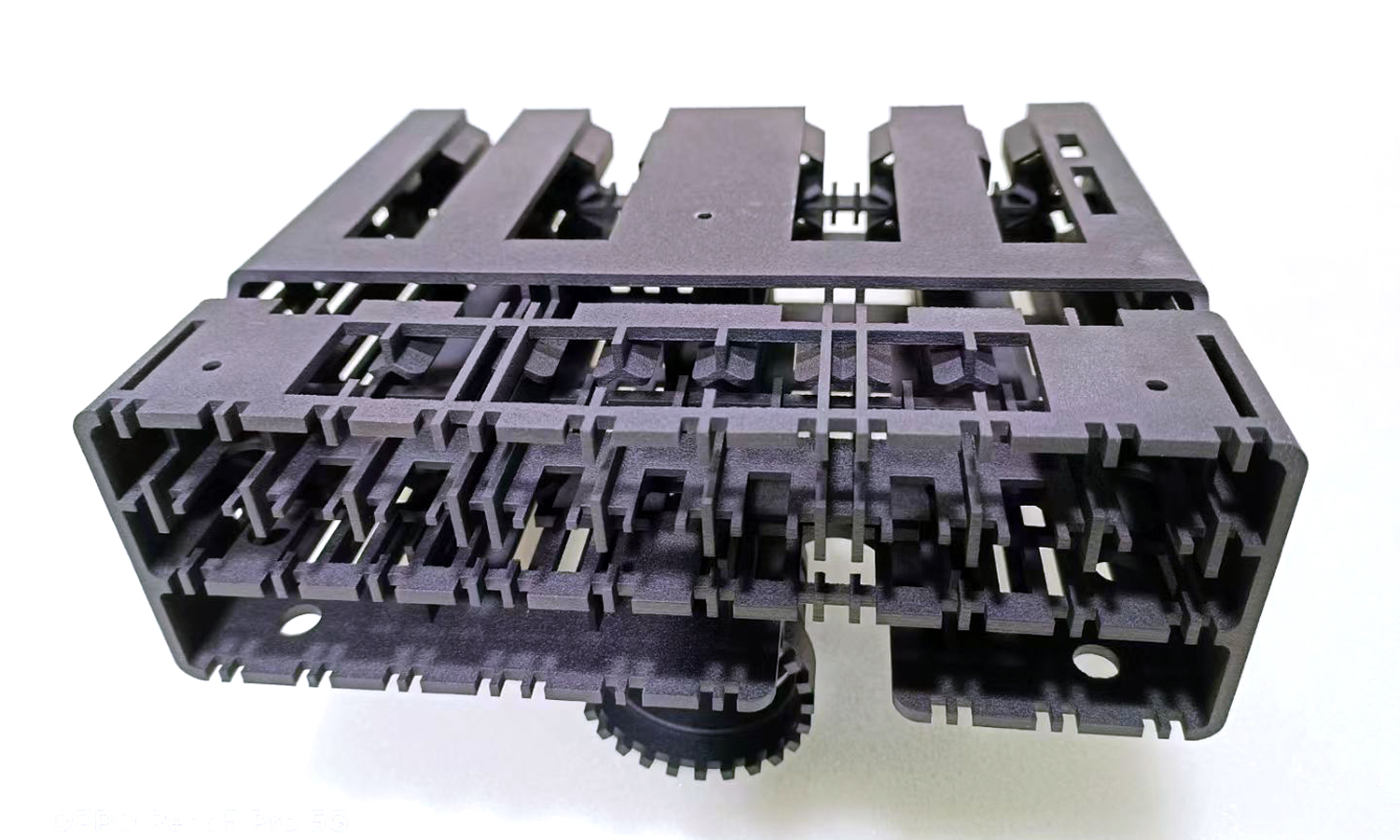

10. Glass-Filled Nylon

Glass-filled nylon is a composite material that incorporates glass fibers into nylon, enhancing its strength, rigidity, and thermal stability. This material is perfect for producing parts that need to withstand high stress and temperature, such as industrial components and structural parts. Glass-filled nylon is often used in applications where high mechanical strength and dimensional stability are required, including brackets, housings, and mechanical fixtures.

Choose FacFox for Your 3D Printing Needs

When it comes to producing high-quality, durable 3D printed parts, selecting the right service provider is just as important as choosing the right material. FacFox offers a comprehensive range of 3D printing services using the strongest materials available in the industry. With advanced technology and a team of experienced professionals, FacFox can help you bring your most ambitious projects to life.

Whether you need prototypes, end-use parts, or complex assemblies, FacFox ensures precision and strength in every print. Their services cater to various industries, including aerospace, automotive, medical, and consumer goods, providing tailored solutions to meet your specific needs. FacFox also offers design assistance, material selection guidance, and post-processing options to ensure your project is successful from start to finish.

Visit FacFox today to learn more about how we can support your 3D printing projects and help you achieve outstanding results. With FacFox, you can trust that your parts will not only meet but exceed your expectations in terms of quality, durability, and performance.