Meet UnionTech Therm 1, our red, transparent SLA Clear High-temp Resin-100℃. This innovative resin boasts excellent high-temperature resistance, enduring over 100℃. For parts thicker than 3mm, it can handle temperatures up to 150℃ without load. Though less impact-resistant than flexible or tough resins, its capabilities are truly remarkable for precision and stability.

Key Features

- High-Temp Resistance: Ideal for environments requiring robust thermal endurance.

- Transparency: Perfect for visual inspection of internal components, vital for industrial and research applications.

- Low-Viscosity: Ensures smooth, fine-detail models with impeccable surface finish.

- Versatile Usage: Suitable for fine-detail models, form and fit testing, and functional prototyping. Not recommended for moving and assembled parts due to its brittleness.

Specifications

- Max Build Size: 600 x 600 x 400 mm

- Min Build Size: 5 x 5 x 5 mm

- Default Layer Height: 0.1 mm

- Optional Layer Heights: 0.1 mm

- Tolerance: ±0.3% (minimum ±0.3 mm)

- Heat Endurance: Up to 102℃

Advantages

- Prototyping for High-Temp Applications: Enables realistic testing and iteration.

- Molding and Tooling: Maintains stability and detail in high-temp processes.

- Transparency for Inspection: Ideal for visual inspection under thermal stress.

- Educational and Demonstrative Uses: Perfect for educational and demonstration purposes.

- Simulation and Testing: Ideal for simulating real-life conditions without risking final products.

Despite not being ideal for end products due to its limited impact resistance, SLA Clear High-temp Resin-100℃ offers significant benefits, pushing the boundaries of 3D printing possibilities.

Test Unit Samples

Each impeller features multiple curved blades radiating from a central hub, creating a circular opening. This design ensures optimal airflow or fluid flow, making them essential components in various machines. They cannot be used as functional parts, but if you wish, you could assemble them onto toy submarines.

Meet Henry, the adorable and fearless mascot of FacFox. These miniature foxes are crafted from a translucent orange resin that gives them a stunning, almost crystalline appearance. Their geometric, faceted design adds a touch of boldness and a stylized look. Different from the first case, we polished the fox before spraying with a thin layer of clear acrylic oil, so the clear one has a much better appearance, the layer lines are nearly invisible.

Each strip features sections clearly labeled with different measurements, ranging from a robust 2.0mm down to a delicate 0.2mm. This allows you to pinpoint exactly where our printer excels and identify potential limitations in handling fine details. From this sample, you could tell that although thickness of 0.2mm could be printed out, both have some unavoidable deformation. Our specialists will examine every 3D model sent from you and inform you the risk of deformation.

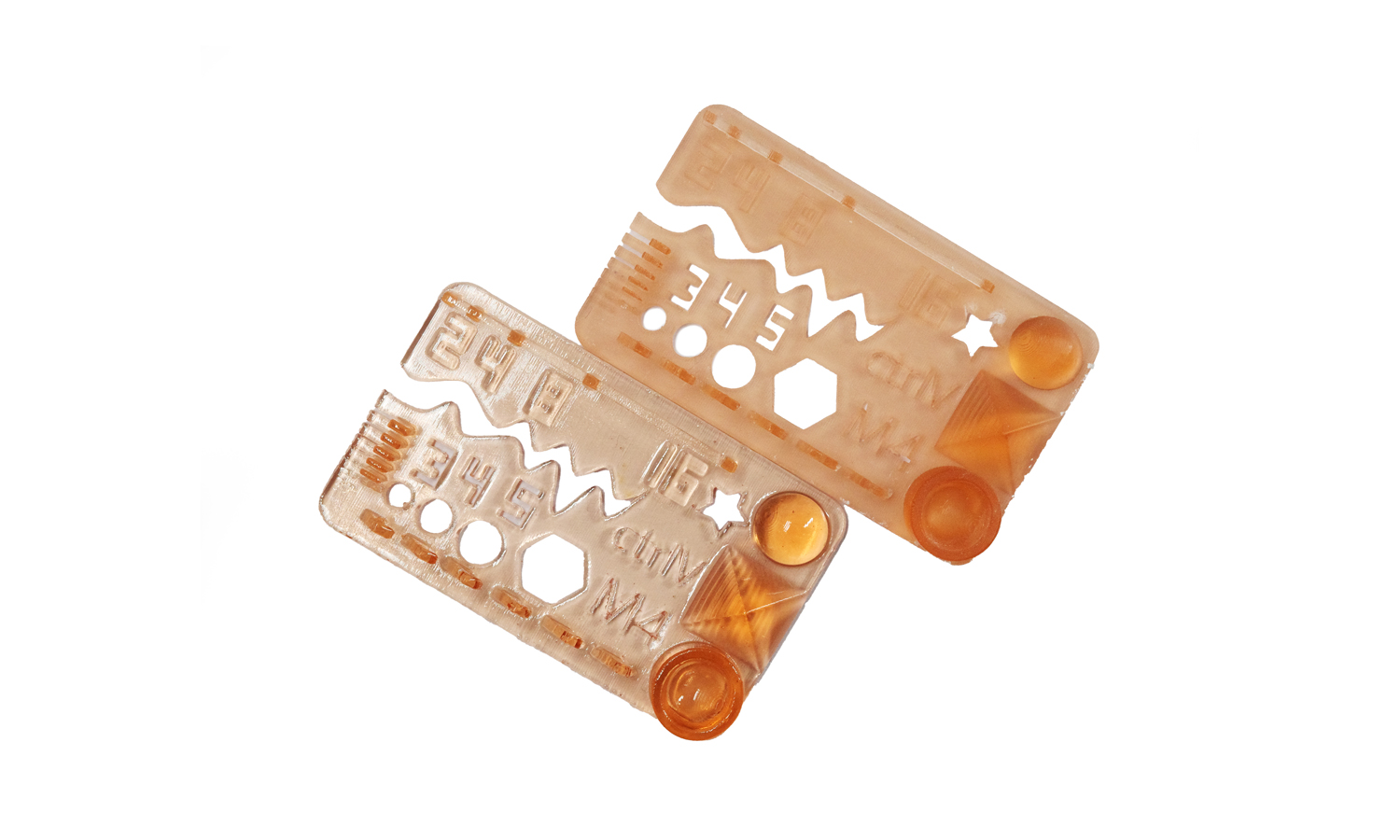

- Cognizable Letters: All hollowed and raised letters are clear and readable, although some show adhesion. We recommend keeping hollowed details larger than 1mm for optimal results.

- Overhang Bridges: The 2mm, 4mm, and 8mm bridges printed successfully, but the 16mm bridge showed deformation. Overhangs at angles less than 45° will require support.

- Surface Finish: Both the clear and frosted benchmarks underwent simple sanding without polishing, leaving visible layer lines. The clear benchmark was enhanced with a thin layer of clear acrylic oil.

- Dimensional Accuracy: While holes and sharp points were not printed perfectly, post-processing could improve their appearance.

- Geometric Variety: The model includes a star, hexagon, and circles, testing the printer’s ability to handle different forms and shapes.

FacFox 3D Printing Services

At FacFox, we transform your creative visions into reality with precision and care. Our cutting-edge 3D printing technology and expert team ensure your projects meet the highest standards of quality and performance. Whether you need detailed prototypes, robust functional parts, or custom solutions, we’ve got you covered. Experience the future of manufacturing with FacFox and elevate your projects to new heights. Ready to revolutionize your 3D printing game? Choose FacFox for unparalleled excellence!