Standard resin works for many applications, but some 3D prints just need more strength. Check out our comprehensive guide on tough resins.

In resin-based 3D printing, each layer is formed by hardening a liquid resin using a light source in a process known as curing. This is the defining trait of resin-based printing, which is also referred to as resin 3D printing or vat polymerization.

Resin printers can achieve a much higher resolution and precision when compared to other desktop solutions such as FDM 3D printing. This is why the technology is often used for aesthetic purposes, like visual prototypes and artistic models, or finely detailed parts, like those found in the jewelry industry.

Yet, ordinary photopolymer resinsare somewhat fragile, and they leave the smaller details on your prints susceptible to cracking and snapping. Some companies have addressed this issue by introducing tougher and more durable resins. This is an especially popular move as resin 3D printing continues to become more common and affordable.

Let’s look at what tough resin is, how it’s used, and how it compares to standard resins.

Introducing Tough Resin

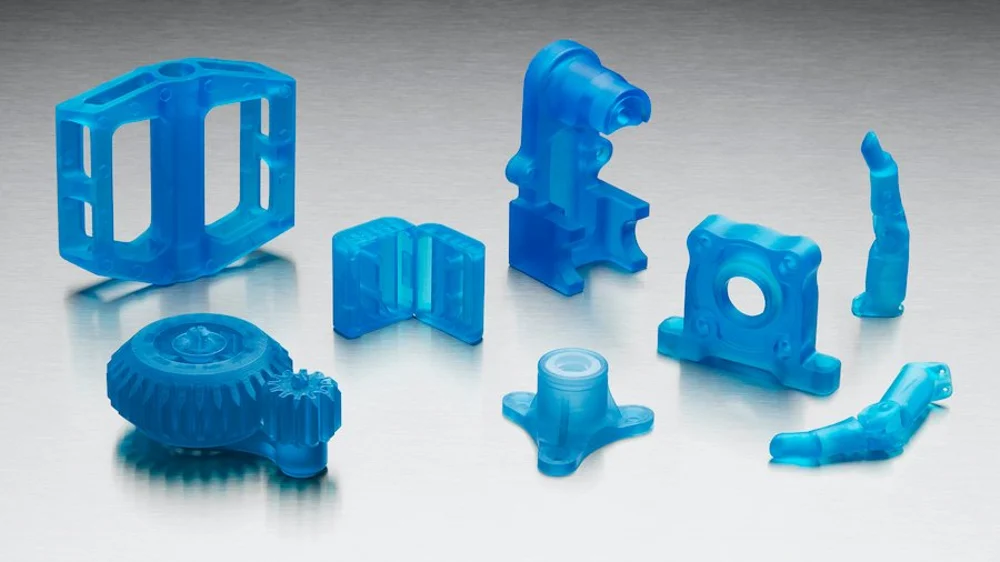

Tough resins are developed for applications requiring materials that can withstand high strain and stress. In fact, the mechanical properties of the cured parts produced by tough resins can even rival industry-grade plastics, as we’ll see later.

Balancing strength and compliance, tough resin is a great choice for strong, functional prototypes and assemblies that need to undergo short periods of mechanical stress. This makes it ideal for wearables, gadgets, and other objects that need to withstand some wear and tear.

Such resins can pose their own challenges when compared to standard resins. Some may require professional 3D printers, and others are simply well above the budget for most hobbyists and home power users.

How Does It Compare?

For comparison, below are some of the main properties of tough and standard resin:

TOUGH RESIN

- Produces sturdy, shatter-resistant parts

- Ideal for functional prototypes and mechanical assemblies

- Has excellent resistance to cyclic loads

- Not suited for thin walls (1 mm is the recommended minimum)

- Harder to remove from the build platform than standard resins

- May cost up to $300/kg

STANDARD RESIN

- Produces fragile parts with low impact resistance

- Ideal for detailed and high-resolution prints

- Produces smooth surface finishes

- Affected by color (like smooth/shiny finishes)

- Relatively easy to use

- Low cost

Useful Tips

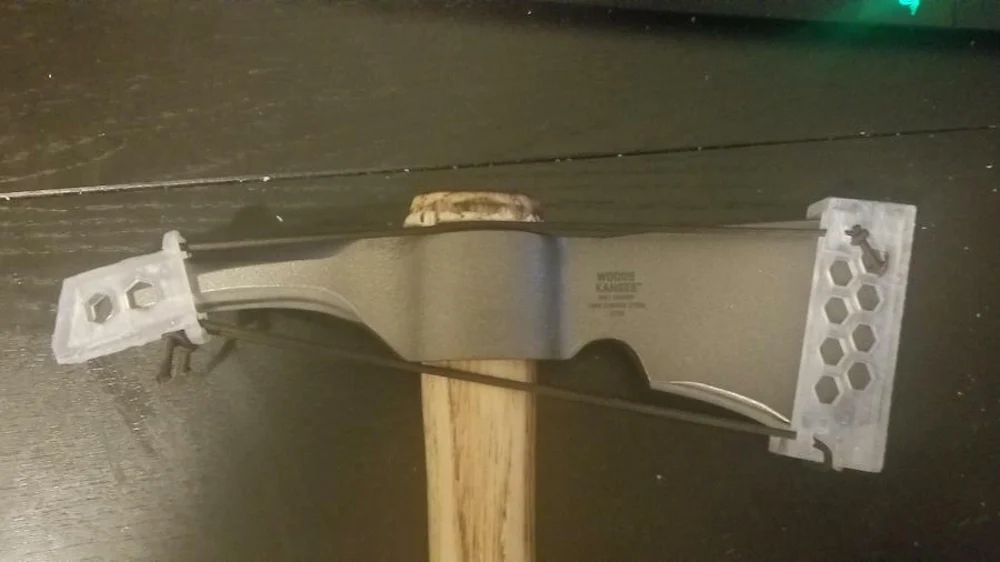

There a handful of general tips when printing with tough resins. While each resin manufacturer provides its own specific recommendations, the following guidelines should also be observed:

- Layer height: Tough resins usually print better at 50 and 100 microns.

- Supports: Avoid printing directly on the build platform, since it can be really hard to remove. Fully supporting the part might be beneficial, as support structures can be broken instead. Warming the build platform with heated air can also make life easier during part removal.

- Cleaning: Unless otherwise stated by the manufacturer, tough resins can be washed in regular isopropyl alcohol (IPA). Make sure you don’t leave the piece in IPA for more than 20 minutes, as this may cause it to become weaker.

- Post-curing: Tough resins reach their optimal properties when properly post-cured. Be sure to follow the instructions from the manufacturer as some resins post-cure better in different wavelengths and with an additional heat source.

Material Properties

Now that we’re well acquainted with tough resins and their peculiarities, let’s dive into some of the best brands and materials for tough resins.

You’ll note that for tough resins, every manufacturer provides technical specifications regarding mechanical behavior. We shouldn’t get into much detail on these properties, although some clarification might be welcome for the uninitiated in material engineering (most of us).

Tensile strength is a value representing the maximum stress (in MPa) that a material can handle, while Young’s modulus evaluates the elasticity of the material and how much strength is necessary to start deforming it.

Finally, Shore D hardness is a test method to evaluate how hard a given material is. The higher the Shore D value, the harder the material is. This relates more to the possibility of indenting the material surface than overall strength per se.

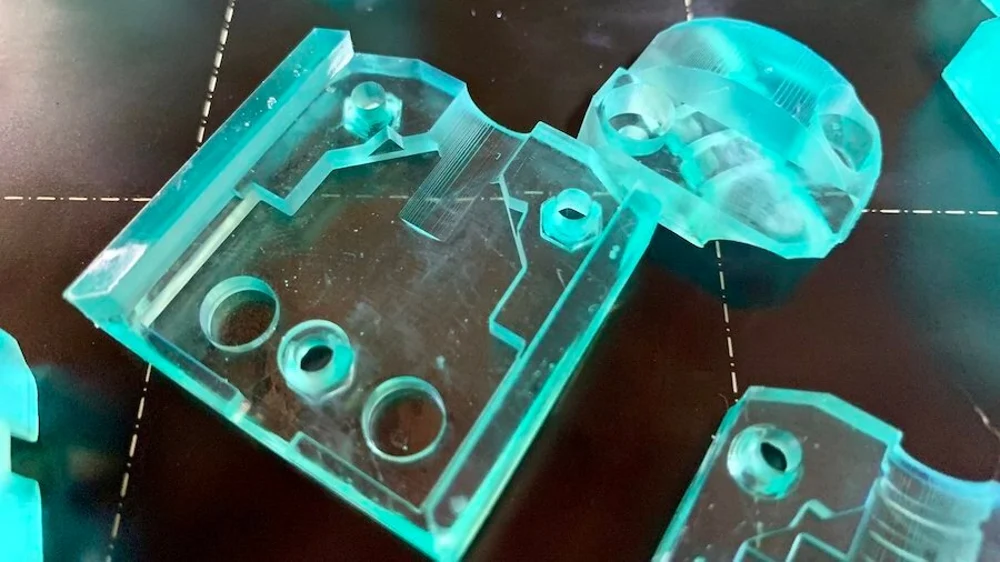

Siraya Tech Blu

Siraya Tech’s Blu is one of the most popular tough resins in the market, partially due to its low price point. At around $50 per kilogram, this resin is comparable to standard resins in cost while still providing better mechanical properties.

Blu is advertised as a fast and easy-to-use resin that works well with most desktop 3D printers as well as common cleaning and post-cure methods. Be aware that it was designed for LCD and DLP printers, not SLA. Siraya recommends printing Blu at temperatures of 25 °C or above, although a heater is rarely required.

- Manufacturer: Siraya Tech

- Tensile strength: 39 MPa

- Young’s modulus: 1500 Mpa

- Shore D hardness: 85

- Color: Translucent blue-green

- Cost: ~$50/kg

Peopoly Moai Tough Resin

Peopoly’s Tough Resin is perfect for true SLA 3D printers. At first, the material will be softer during the printing process. This is why the folks at Peopoly recommend using extra support and preferably at temperatures of 25 °C or higher.

For post-processing, this resin needs some extra care: at least 30 minutes of post-curing with parts submerged in water. However, all of these steps will eventually pay off, resulting in smooth and very tough parts at a very low cost.

For more detailed instructions on how to print with Peopoly’s Tough Resin, check out their printing guide.

- Manufacturer: Peopoly

- Tensile strength: 45 MPa

- Young’s modulus: 1500 MPa

- Shore D hardness: 84

- Color: Transparent

- Cost: ~$55/kg

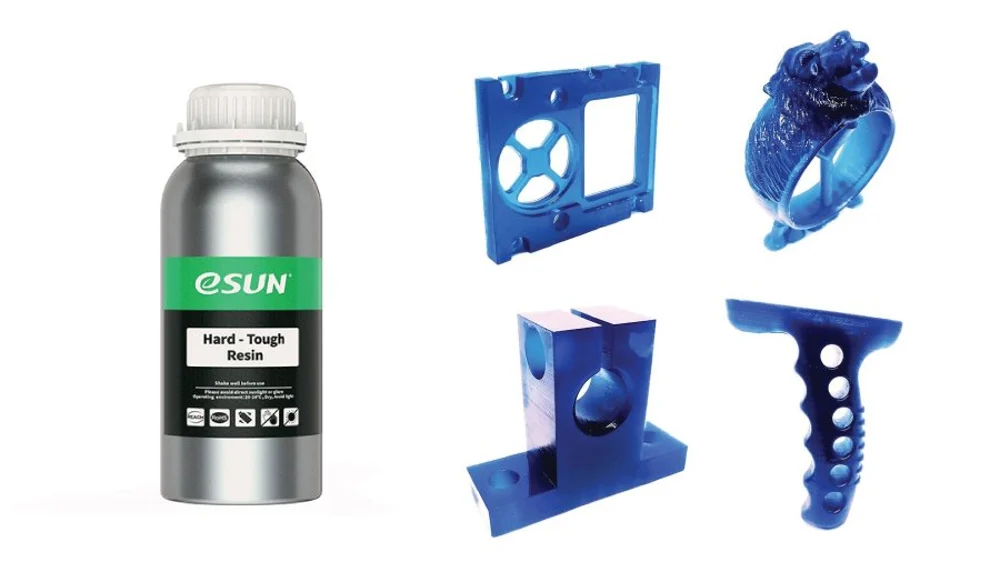

eSun Hard-Tough Resin

eSun’s Hard-Tough resin is a urethane acrylate photocurable resin appropriate for LCD printers. It claims to have hardness and toughness comparable to ABS filament, able to produce prints that can withstand impact and wear.

When it comes to usage, it’s recommended to print at temperatures between 18 and 35 °C, and the resin could potentially be pre-heated to 60 °C, as stated by the manufacturer. For post-processing, eSun also recommends placing the parts in a 50 °C oven for 20 minutes after the post-cure step.

For more information on instructions and precautions, refer to eSun’s printing guide.

- Manufacturer: eSun

- Tensile strength: 55-60 MPa

- Young’s modulus: Not listed

- Shore D hardness: 81

- Colors: Blue, white, black

- Cost: ~$65/kg

Formlabs 2000

Formlabs’ Tough 2000 resin is a reformulated version of their old Tough Resin. According to the company, it’s the strongest resin in its portfolio, offering the same if not better properties than those of ABS plastic.

As with any Formlabs material, Tough 2000 was developed for use in their own machines, namely the Form 2 and Form 3. Formlabs highly recommends post-curing times of 60 minutes at 70 °C to bring out the best mechanical properties.

- Manufacturer: Formlabs

- Tensile strength: 46 MPa

- Young’s modulus: 2200 MPa

- Shore D hardness: Not listed

- Colors: Gray

- Cost: ~$175/kg

Liqcreate Strong-X

Liqcreate’s Strong-X is perhaps the toughest resin on this list. Boasting a 91 MPa tensile strength and 135 Mpa flexural strength, it can easily be applied for heavy-duty uses. Strong-X also provides a high-temperature resistance, enough even for injection molding applications.

The coolest thing, however, is that it can be printed on most budget DLP and LCD printers, including the Anycubic Photon, Elegoo Mars, or Wanhao D7. (See full compatibility list.) The only downside is cost: Priced at around $195 per kilogram, it’s one of the most expensive resins in the market.

- Manufacturer: Liqcreate

- Tensile strength: 91 MPa

- Young’s modulus: 2500 MPa

- Shore D hardness: 87

- Colors: Gray

- Cost: ~$195/kg (~€160/kg)

Loctite 3843 HDT60 High Toughness

Loctite is a brand best known for its adhesives, sealants, and chemicals in general. While photocurable resins fit the description, it might come as a surprise that Loctite produces and sells resins for 3D printing.

Loctite 3843 HDT60 High Toughness resin is a professional material that provides high impact strength and moderate temperature resistance. It’s compatible with any DLP printer that covers the 386 nm wavelength spectrum.

This material is extensively documented, from printing settings to post-curing instructions, so be sure to check its datasheet for more information.

- Manufacturer: Loctite (Henkel Adhesives)

- Tensile strength: 51 MPa

- Young’s modulus: 1800 Mpa

- Shore D hardness: 75

- Colors: Black, white, clear, gray

- Cost: ~$180/L (black), ~$220/L (other colors)

B9Creations Gray Resin

While marketed as a prototyping resin, the superb mechanical properties of B9Creations’ Gray Resin can easily be put in the tough resin category. It’s intended for B9 DLP machines, but it’s compatible with third-party machines, too.

Besides the high-strength, high-impact properties, this material maintains its shape and dimensions by post-curing. In addition, it can be printed at extremely high speeds – up to 100 mm/hour – without sacrificing quality

- Manufacturer: B9Creations

- Tensile strength: 44.6 MPa

- Young’s modulus: 2110 Mpa

- Shore D hardness: 87

- Colors: Gray

- Cost: ~$190/kg

EnvisionTEC E-Rigid PU

To finish off this strong list, we have EnvisionTEC’s E-Rigid. This is a polyurethane-based resin that can produce parts that rival injection molded ones. It is available in three colors: natural, black, and white, with the latter displaying the best mechanical properties.

The E-Rigid polyurethane is a versatile and tough material, ideal for both functional prototyping applications and producing end-use parts. It’s by far the most expensive material on this list, being more suitable when polyurethane properties are required.

- Manufacturer: EnvisionTEC

- Tensile strength: 34 MPa (white)

- Young’s modulus: 700 Mpa (white)

- Shore D hardness: 78 (white)

- Colors: Black, white (tougher)

- Cost: ~$310/kg (~£225/kg)

Source: https://all3dp.com/2/best-tough-resin-abs-like-resin/