Introduction

Similar to other 3D printing processes, metal 3D printers add materials layer by layer based on the 3D design to make parts – which is called additive manufacturing.

In this way, the material can be processed into complex structural parts that cannot be produced by traditional subtractive manufacturing (CNC machining) or form manufacturing (metal casting) technology and does not require special tools (such as molds).

Metal 3D printing mainly has the following processes:

Powder Bed Fusion

High-energy laser (in DMLS / SLM) or electron beam (EBM) is used selectively to bond metal powder particles together to form metal parts layer by layer.

- Major equipment suppliers: EOS, 3D Systems, Renishaw, SLM Solutions, Concept Laser, Arcam, Huashu, Platinum Laser

Binder Jetting

The metal powder particles are layer-by-layer bonded together by the adhesive to form the main body. After the heat treatment, the adhesive is removed and the metal powder is sintered to form an all-metal molded part.

- Major equipment vendors: Desktop Metal, ExOne, Digital Metal, HP

Metal Material Extrusion

A filament or rod-like material composed of a thermoplastic polymer and a large amount of metal powder is melted out of a nozzle (such as FDM machine) to form the main body, and then post-processed (degreasing and sintering) to form an all-metal part.

- Major Equipment Manufacturers: Desktop Metal, Markforged

Direct Energy Deposition

Metal powder or metal wire is melted directly under high energy, and stacked and formed layer by layer.

- Major Equipment Vendors: Optomec, Sciaky

Ultrasonic Additive Manufacturing

After the metal sheet is laid, it is welded to the previous layer with ultrasonic waves, and then formed into a design shape by CNC machining. Then repeat the same process on the next layer.

- Major equipment supplier: Fabrisonic

Other Techniques

Other metal 3D printing systems have been developed for many years and are based on established plastic 3D printing technologies (such as material spraying or SLA).

3D printing is also used to make tools for traditional metal manufacturing methods such as sand casting or investment casting.

- Major equipment vendors: Xjet (nano jet), ExOne (sand mold), Xerox (Vader Systems electromagnetic spray metal 3D printing technology)

Strengths and Limitations of Metal 3D Printing

Strengths

- Production of complex parts with no additional cost

Compared with traditional manufacturing, the biggest advantage of metal 3D printing is its unique design flexibility. Since no specific tools (eg, molds or knives) are needed, geometric designs that cannot be manufactured by other processes can be easily 3D printed. More importantly, increasing the geometric complexity of a part has little effect on its manufacturing cost. This means that organic, topologically optimized structures can be manufactured using metal 3D printing, which greatly improves the performance of production parts. - Structural optimization to achieve more lightweight design

The high design flexibility supported by metal 3D printing is closely related to the creation of lightweight structures. The best design based on metal 3D printing will give a lightweight solution. Advanced CAD techniques, such as topology optimization and generative design, are often used for this purpose. This makes parts lighter (typically 25% to 50%) and more rigid. This is critical for high-end applications in industries such as aviation and aerospace. - Increase component functions

3D printing can make parts with internal structures, such as parts with internal channels. If you print molds with shaped water-cooled channels, you can reduce the injection cycle by up to 70%. - Combines components which are originally produced separately due to manufacturing restrictions into one part

- Simplify the manufacturing process

Even if parts with complex geometries can be made using “traditional” methods, more than 20 production steps may be required.In these cases, choosing metal 3D printing may significantly reduce the production process. For example, using adhesive spraying, the total number of steps can be reduced to 5 or less (including post-processing and finishing). This greatly reduces the complexity of the manufacturing supply chain. - Excellent material properties

In contrast to 3D printing of plastics, parts made with DMLS / SLM or adhesive spray exhibit isotropic mechanical property. In addition, their material strengths are comparable (and in some cases even better) to wrought metals. For this reason, metal 3D printed parts are used in the most demanding industries such as aerospace. However, it should be noted that the fatigue strength of 3D printed parts is usually low. This is due to its surface roughness and internal porosity (typically, the porosity of DMSL / SLM parts is less than 0.2%, while the porosity of adhesive-jet parts is less than 2%).

Limitations

- Higher cost than traditional manufacturing

- No economies of scale, not suitable for mass production

- Special design rules the design of metal 3D printed parts follows a different set of rules than traditional manufacturing. This usually means that existing designs must be revised. In addition, the tools provided by older CAD software may not be sufficient to take full advantage of the benefits of metal 3D printing.

- Basically, all printing needs post-processing

Application of Metal 3D Printing

Here are some examples of key industrial applications for metal 3D printing. They illustrate some of the main advantages and limitations of technology. They can be used to better understand why engineers choose metal 3D printing in some specific circumstances.

Aerospace

Creating lightweight structures is critical to the aerospace industry. The current cost of launching a kilogram of payload into space is approximately $ 10,000 to $ 20,000. Therefore, metal 3D printing of topologically optimized parts has great potential.

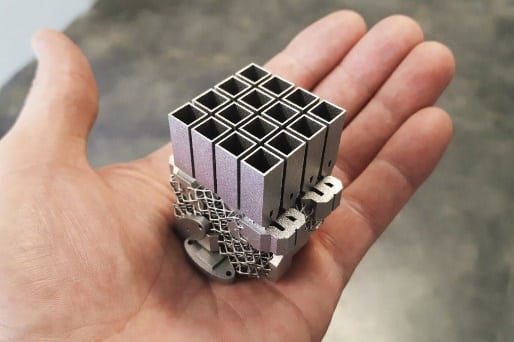

For example, Optisys is a supplier of miniature antenna products. They used DMLS / SLM to reduce the number of discrete parts in the tracking antenna array from 100 to 1. Through this simplification, Optisys successfully reduced production time from 11 months to 2 months, while reducing weight by 95%.

Medical

Metal 3D printing can quickly create complex organic structures in the medical industry, providing customized parts for everyone. Medical implants made of biocompatible materials such as titanium are one of the main uses of metal 3D printing.

Back in 2007, Dr. Guido Grappiolo became the first surgeon to implant 3D printed hip implants. He designed the Delta-TT Cup, a lattice-structured titanium implant that accelerates recovery and bone growth of patients. Ten years later, more than 100,000 such hip cups were successfully implanted in patients.

Automotive

In the automotive industry, the options for adopting metal 3D printing as a terminal component are rapidly increasing. Currently, high performance and racing are the main applications for metal 3D printing.

The student team of Delft University of Technology is one of the most successful teams in the history of motorcycle racing, and they use DMLS to make topologically optimized brackets for their formula cars. This bracket is the main connection point between the wheel and the chassis, and it is designed to withstand forces up to 400 kg. The redesigned titanium bracket halves in weight and is twice as strong as its equivalent.

Industrial tools

Metal 3D printing is used to create industrial tools with additional functions. These advanced tools can greatly increase the productivity of other processes.

For example, metal molds with internal cooling channels can be manufactured using DMLS / SLM 3D printing. These cooling channels can be designed into a more optimized structure than under traditional processes. The cost of a printed metal mold is about $ 1,000, compared to $ 4,000 of the same CNC machining mold. The increased cost brings significant performance improvements. Users report that the cycle time for injection molding has been shortened by 60% to 70%, and there is almost no scrap during processing.

Product Development

The main application of metal extrusion is the manufacture of metal prototypes. Compared with other solutions, the time saved by metal extrusion can greatly accelerate new engineering products from R&D to marketing.

Lumenium is a startup that develops innovative internal combustion engines. They are looking for a faster and more cost-effective way to make prototypes of engine parts. Traditionally, their development cycle is about 3.5 years. By adding metal extrusion to their workflow, they estimate that they have reduced development time by 25% to 2 years and 9 months.

Metallic 3D Printing Materials

The number of metallic materials available for metallic 3D printing is rapidly increasing. The main alloys currently used include:

Stainless steel

It has high tensile strength, high-temperature resistance, corrosion resistance. Stainless steel is a metal alloy with high ductility, wear-resistance, and corrosion resistance. It’s easy to weld, process, and polish.

Tool steel

Titanium alloy

It’s commonly used in aerospace, automotive and medical industries and has an excellent strength-to-weight ratio. Titanium is a metal with excellent strength-to-weight ratio, low thermal expansion, and high corrosion resistance. It’s sterilizable and has good biological compatibility.

Aluminum alloy

Aluminum alloy has good workability and ductility, good strength-to-weight ratio. Aluminum is a metal with a good strength-to-weight ratio, high thermal conductivity, and electrical conductivity, low density, and natural weather resistance.

Ni-based superalloy

Superalloys are used in extreme environments, eg. the aerospace applications. Among them, Nickel alloys have excellent strength and fatigue resistance. It can be used for a long time at temperatures above 600 ° C.

Cobalt-Chromium Alloy

It’s suitable for extreme environments, aerospace, and biomedical fields. CoCr is a metal superalloy with excellent strength, corrosion resistance, wear-resistance, and high-temperature resistance.

Copper Alloy

Precious Metals

Gold, silver, platinum…

Rare Metals

Palladium, tantalum…

Metallic Printing Speed

Metal 3D printing takes about 48 hours and an average of 5 days to manufacture and complete.

Approximately 50% of production time is used for printing. At present, the printing speed of the mainstream metal 3D printing system is about 10-40 cm³ / h.

The remaining production time is related to post-treatment and surface treatment requirements. Heat treatment accounts for a large part of the total production time: a standard thermal cycle lasts 10 to 12 hours. Surface polishing is also a time-consuming step, as polishing requires machining (five-axis CNC machining) or manual (manual polishing) for secondary processing.

Comparison of metal printing and traditional manufacturing

Before production, we mainly compare additive manufacturing with subtractive manufacturing (CNC processing) and molding processes (casting) from the aspects of cost (time and price) and product performance.

Generally speaking, the manufacturing cost is mainly related to the yield, and the performance of a part depends largely on its structure.

The key advantage of metal 3D printing is its ability to create parts with complex and optimized geometries. This means it is ideal for manufacturing high-performance components. On the other hand, it lacks the effect of scale, and it is not as fast and cost-effective as the CNC machining or metal casting in the production of batch parts.

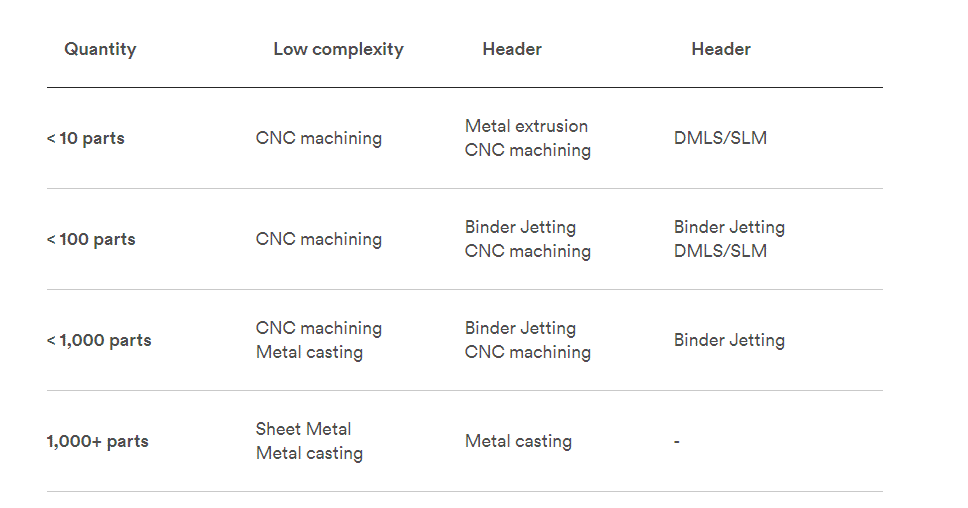

Each metal 3D printing process can meet different industrial needs. Use the following tips as general guidelines to understand which method works best:

- DMLS / SLM is the best solution for high structural complexity (organic, topologically optimized) components that require excellent material properties to increase the efficiency of the most demanding application environments.

- Binder spraying is the best solution for low-to-medium batch production. The unit cost of production is lower than the molding process that requires huge up-front investment, the structure is more complex, and small and medium batch parts with high CNC processing costs can be considered.

- Metal extrusion is the best solution for metal prototypes and disposable parts that require five-axis CNC machining.

The following table is a matrix of quantity and structural complexity, which roughly shows the adaptation scenarios of each manufacturing process (addition, subtraction or molding process) for reference:

Introduction of SLM and DMLS Process

Direct metal laser sintering (DMLS) and selective laser melting (SLM) are the most commonly used 3D printing processes for metals. They are particularly suitable for high-end applications because they provide great design freedom and excellent material properties.

Direct Metal Laser and SLM Selective Laser Melting are two types of powder bed cladding metal 3D printing technologies. The actual difference between SLM and DMLS is very small. For design purposes, these two technologies can be considered the same.

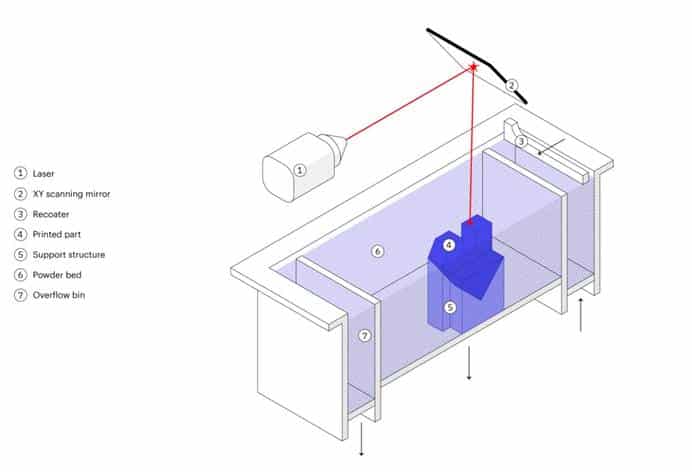

They all use high-power lasers to bond metal powder particles together, forming layers of parts. SLM achieves complete melting of a single metal, while DMLS causes metal particles to fuse together at the molecular level due to extremely high temperatures. Most metal alloys are compatible with the DMLS process, but only some pure metal materials are printed with SLM.

Processing method

Here are the basic steps of the DMLS / SLM 3D printing process:

- The construction chamber is first filled with inert gas and then heated to the optimum printing temperature.

- Place a thin layer of metal powder (usually 50 μm) on the build platform.

- The laser scans the cross-section of the part to selectively bond metal particles.

- After scanning one layer, the platform moves one layer lower and repeats this process until the entire build is complete.

- After printing, you need to cool down first, and then remove the powder.

3D printing is just the beginning of the DMLS / SLM manufacturing process. After printing, several (required or optional) post-processing steps are required. The necessary post-processing steps include:

- Stress Relief: Due to the high processing temperature during printing, internal stress will be generated. These need to be eliminated by thermal cycling before any other operation.

- Removal of parts: In DMLS / SLM, parts are basically welded to the build platform. Need to be cut with a saw or wire.

- Support removal: Support in DMLS / SLM is required, mainly to reduce warping and distortion that occurs during printing. The support can be dismantled manually or numerically controlled.

To meet engineering requirements, additional post-processing steps are usually required, which may include:

- CNC machining: When tolerances smaller than the standard ± 0.1 mm are required, you need to use CNC machine tools for finishing.

- Heat treatment: In order to improve the material properties of parts, heat treatment or hot isostatic pressing (HIP) can be used.

- Smooth / Polish: Some applications require a smooth surface. CNC machining / manual polishing/vibration or chemical polishing are all available solutions.

Advantages and disadvantages

- High design freedom

- High accuracy and fine details

- High-performance materials

- High manufacturing and design costs

- Parts made with DMLS / SLM can have complex, organic structures that minimize weight or maximize strength. Some structures cannot be processed in one piece by other processes.

- There are many choices of materials, a variety of metals or alloys can be selected for processing, and the internal porosity of the molded parts is low, and the performance is excellent.

- The cost is relatively high and it is only suitable for some special application.

- In order to prevent deformation, a large number of support structures are required for printing, and the support is difficult to remove. The surface of the print is worse than other processes and requires complicated post-processing.