Creating lightweight metal parts is the holy grail for high-performance industries like automotive and aerospace — which is why manufacturers are continually striving to find new ways to design and manufacture lighter metal parts with enhanced part performance. 3D printing, with its capacity to create complex designs, could be the solution to the growing need for lightweight metal components.

Why do manufacturers strive for lightweight metal parts?

Industries like aerospace and automotive face the challenge of optimising fuel consumption efficiency, reducing production costs and meeting stringent regulatory standards on harmful emissions. Lightweighting, the practice of making parts lighter, is one solution to dealing with these challenges.

Lighter parts mean lighter vehicles and aircraft, resulting in less fuel consumption and a reduction in emissions. Metal lightweighting is difficult to achieve with traditional manufacturing methods due to longer lead times and the lack of an economically viable way to produce complex geometries. High material wastage and tooling costs (in the case of injection moulding) are also prohibitive factors.

3D printing: the metal lightweight solution

Sending a 22-ton aircraft payload into Low Earth Orbit costs $62 million — almost $3,000 per kilo — according to research conducted by 3D Systems. Since every kilogram removed from the overall weight of an aircraft translates into cost savings, weight production, therefore, becomes a key priority. Similarly, the lighter the part, the less material that has been used to produce it, which, again, brings down manufacturing costs.

3D printing is a manufacturing technology that creates parts layer by layer, using material only where needed. Unlike traditional production techniques, 3D printing turns complexity into an asset, creating an opportunity to cost-effectively manufacture lightweight, complex metal parts.

Apart from being the more cost-effective option for producing lighter metal parts, the 3D printing process is typically faster than traditional manufacturing processes. As a toolless technology, additive manufacturing creates parts directly from digital files, significantly accelerating the manufacturing process.

Typically, powder bed fusion processes are chosen to produce lighter metal components. With the help of a laser, layers of metal powders are fused together, allowing geometrically complex lightweight structures to be produced.

How can 3D printing make metal parts lighter?

Using advanced design software

Successfully using 3D printing to create lightweight parts always begins with the design. Thanks to the design freedom offered by 3D printing, the technology can be seamlessly coupled with advanced design software, including generative design, topology optimization and lattice-building software, to name a few.

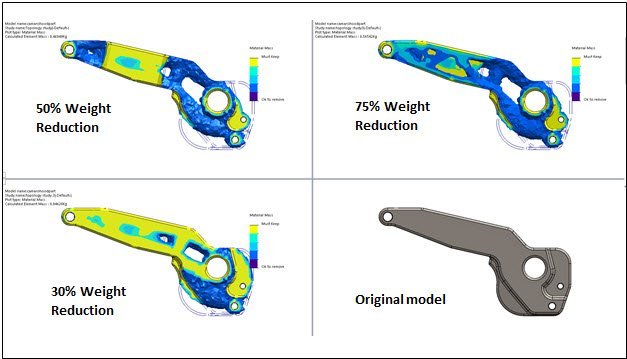

Using sophisticated algorithms, topology optimisation and generative design tools help to optimise the geometry and material distribution of a part. By adding or removing the material in places, defined by a set of parameters, these tools allow engineers to explore endless design options and find the best possible lightweight structure of a given part.

General Motors, for example, is already using these advanced technologies to make vehicle models with an average weight reduction of more than 150 kg per vehicle.

In another example, a staggering 70% weight reduction has been achieved with a topologically optimised, 3D printed titanium bracket for GE Aircraft. Using Frustum’s Generate topology optimisation software, engineers were able to determine the most efficient material distribution within the bracket to meet the performance requirements.

Design optimisation also means that the part count can also be reduced. By combining several structural components into one, a lighter, more efficient part can be produced. Airbus has already equipped the A380 aircraft with a 3D-printed titanium actuator valve block, which weighs 35% less than traditionally manufactured counterparts, and is made of fewer parts.

Applying internal lattice structures is another design approach in reducing the weight of a metal part. Non-structural solid metal parts are the ideal use case for redesigning them with latticework, making then lighter whilst preserving full functionality.

Using materials for enhanced properties

New materials for 3D printing are constantly evolving, further pushing the envelope on what can be achieved with metal lightweighting. Scalmalloy is a great example: developed by APWorks, Scalmalloy is a metal powder alloy which combines the lightness of aluminium with almost the same specific strength and ductility of titanium. The high strength to weight ratio of Scalmalloy makes this material particularly sought after in the aerospace and automotive industries where it can be used to produce lightweight yet highly strong functional components.

Metal Matrix Composites (MMC) also show great promise for metal lightweighting. MMCs are composite materials that consist of metal and another metal or ceramic and organic compounds. Although MMCs are novel materials in additive manufacturing, the technology could provide new opportunities for producing parts with these high-performance lightweight materials, featuring high strength and stiffness. Elementum3D, for example, is developing a metal and ceramic composite specifically for metal 3D printing. This material will be able to produce strong, lightweight, heat-resistant metal parts such as aerospace or car engine components.

The growing value of metal lightweight

Successfully 3D printing metal parts requires knowledge about the possibilities and limitations of metal AM technologies and materials. The key challenge is, therefore, rethinking traditional approaches to design, and instead designing specifically with the needs of additive manufacturing in mind.

As the quest for metal lightweighting gains traction, manufacturers across high-performance industries are tasked with balancing the competing goals of maximising strength and performance while minimising the weight of parts.

3D printing offers an ideal solution in balancing these goals, especially when coupled with advanced design software and materials. Admittedly, we’ve only begun to scratch the surface of what’s possible with metal 3D printing. However, the possibility of creating lightweight parts with faster lead times while reducing production costs will allow manufacturers to reap the benefits of bringing better, lighter and more efficient products to the market.