CNC Machining and 3D Printing are two of the most commonly used manufacturing processes in the world today. These two technologies have revolutionized the way that products are designed and produced. However, there are significant differences between them.

In this article, we will explore the pros and cons of both CNC machining and 3D printing, and help you decide which method will work better for your specific needs.

CNC Machining

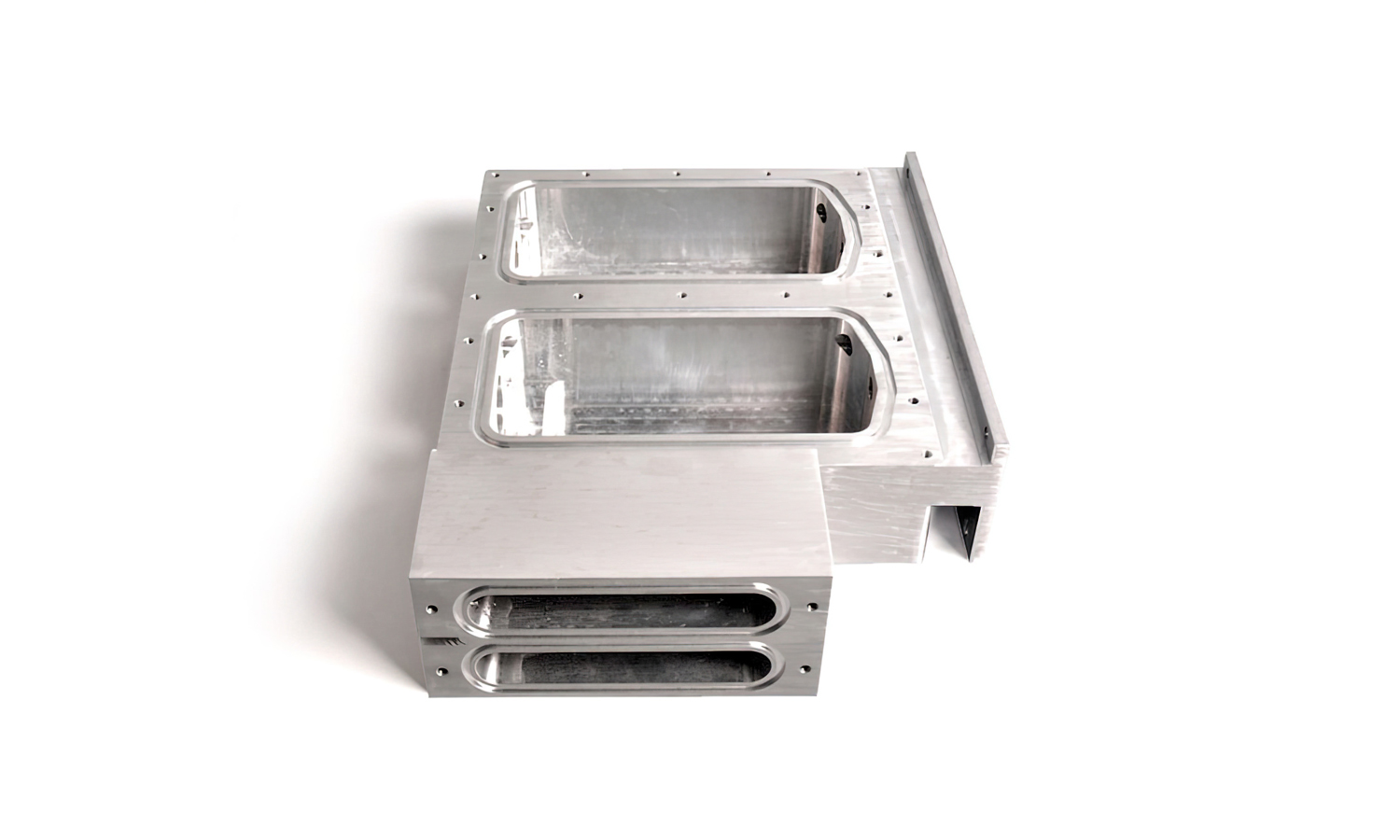

CNC Machining is a manufacturing process that involves the use of computer-controlled machines to shape and cut materials into precise shapes. The process involves the use of various cutting tools to remove material from a block of material. CNC Machining can be used to create everything, from small parts for electronics to large structural components for machinery.

One of the main benefits of CNC Machining is its precision. CNC machines can create parts that are incredibly accurate, with tolerances as low as 0.001 inches.

Another advantage of CNC Machining is its versatility. CNC machines can work with a wide range of materials, including metals, plastics, and even wood.

However, there are also some drawbacks to CNC Machining. One of the main disadvantages is the cost. CNC machines can be expensive, and the process can be time-consuming.

Additionally, CNC Machining is generally not well-suited for creating parts with complex geometries.

3D Printing

3D Printing, on the other hand, is a process that involves the creation of a physical object from a digital model. The process involves the layer-by-layer addition of material, such as plastic or metal powder, until the final product is complete. 3D Printing is incredibly versatile and can be used to create everything from toys to prosthetic limbs.

One of the main benefits of 3D Printing is its speed. 3D printers can create complex parts in a matter of hours, rather than days or weeks. Another advantage of 3D Printing is its flexibility. 3D printers can create parts with complex geometries that would be difficult or impossible to create with CNC Machining.

However, there are also some limitations to 3D Printing. For example, 3D printers can only work with certain materials, and the strength and durability of 3D printed parts may not be as good as those created with CNC Machining. Additionally, 3D printing is generally best suited for small to medium-sized parts, while CNC Machining can be used to create parts of virtually any size.

CNC Machining vs. 3D Printing

So, which is better: CNC Machining or 3D Printing? The answer is that it depends on what you’re trying to achieve. If you need parts that are incredibly precise and have tight tolerances, then CNC Machining is probably the better option. On the other hand, if you need parts with complex geometries or want to create custom parts quickly and affordably, then 3D Printing is likely the better choice.

Here are some factors you can consider when making decisions.

Numbers of Parts

| Number of parts | 1-10 | 10-100 | 100-1000 | 1000+ |

|---|---|---|---|---|

| Plastic | 3D printing | 3D printing (consider CNC) | CNC machining (consider injection molding) | Inection molding |

| Metal | 3D printing & CNC machining* | CNC machining (consider 3D printing) | CNC machining (consider investment casting) | Investment or die casting |

*this is highly dependent on part geometry | Source: Hubs.com

Dimensional Accuracy

| Technology | Tolerance | Minimum wall thickness | Maximum part size |

|---|---|---|---|

| CNC machining | ± 0.025 – 0.125 mm* | 0.75 mm | Milling: 2000 x 800 x 1000 mm Lathe: Ø 500 mm |

| SLS | ± 0.300 mm | 0.7 – 1.0 mm | 300 x 300 x 300 mm |

| FDM | Desktop: ± 0.500 mm Industrial: ± 0.200 mm |

0.8 – 1.0 mm | Desktop: 200 x 200 x 200 mm Industrial: 900 x 600 x 900 mm |

| SLM/DMLS | ± 0.100 mm | 0.40 mm | 230 x 150 x 150 mm |

| Binder jetting | ± 0.200 mm | 2.0 mm | 380 x 355 x 735 mm |

*According to the specified level of tolerance | Source: Hubs.com

It’s also worth noting that there are some applications where the two technologies can be used together. For example, CNC Machining can be used to create molds that can then be used in the 3D Printing process. This can help to create complex parts more quickly and affordably than using either technology on its own.

Conclusion

In conclusion, both CNC Machining and 3D Printing have their strengths and weaknesses. The key is to determine which method will work best for your specific needs. Whether you need parts that are incredibly precise or want to create custom parts quickly and affordably, there is a manufacturing process that can help you achieve your goals. So, do your research, weigh the pros and cons, and choose the method that will help you achieve the best results.

We are ready to assist you with your CNC machining and 3D printing requirements. Please feel easy contacting us via info@facfox.com.