If you are looking for a way to create customized miniatures and statues with realistic colors and details, you might want to check out FacFox’s full-color printing technologies. We offer two types of 3D printing processes that can produce full-color parts without painting: PolyJet 3D printing and Binder Jet 3D printing. Both processes have their own advantages and applications, depending on your needs and preferences. In this article, we will explain how these two technologies work, what materials they can use, and what benefits they can offer for your projects. Let’s begin!

What files are required for FacFox’s colorful 3D printing services?

Both PolyJet and Binder Jet technologies can directly produce colorful models without painting, as long as your model has colors.

To make things easier, here are some eligible files for colorful 3D printing:

- OBJ file with texture files (.bmp / .jpg / .tiff / .png)

- VRML file with texture files (.bmp / .jpg / .tiff / .png)

- OBJ / VRML / 3MF file that contains color information in itself

The OBJ file is a 3D model file that can save the shape and topology information of the model. The MTL file is a material library file that can save the material properties and texture paths of the model. The PNG file is an image format that can save the color, texture and transparency information of the model.

Polyjet Full-color Printing

PolyJet is a type of material jetting technology that uses a print head to spray tiny droplets of liquid photopolymer resin onto a build platform. The resin is then cured by UV light to form solid layers. PolyJet resin can print in multiple colors by mixing different resins in the print head. PolyJet resin can also print with different materials that have different properties, such as rigid, flexible, transparent, or opaque.

At FacFox, the material we use for PolyJet full-color printing is PolyJet Vero+Agilus, and we call it PolyJet Multi-Color Resin.

Binder Jet Full-color Printing

Binder Jet sandstone is a type of powder bed fusion technology that uses a print head to deposit droplets of colored binder onto a bed of fine sandstone powder. The binder acts as a glue that binds the powder together to form solid layers. Binder jet sandstone can print in full color by using CMYK (cyan, magenta, yellow and black) binders that blend together to create various hues.

At FacFox, the material we use for PolyJet full-color printing is 3D Systems VisiJet PXL, we name it as CJP Fullcolor Sandstone.

Comparison of PolyJet and Binder Jet

Both PolyJet resin and binder jet sandstone can produce colorful 3D prints with high resolution and smooth surface finish. However, they also have some differences that may affect their suitability for different applications.

PolyJet resin has some advantages over binder jet sandstone, such as:

- Higher accuracy: PolyJet can print with layer heights as low as 16 microns, while binder jet typically prints with layer heights of 100 microns or more.

- More optical properties: PolyJet can print resins that have different transparency, while binder jet only produce opaque prints. Thus Polyjet is used to create realistic medical models like anatomical teaching models of human organs.

- Better surface quality: PolyJet prints are known for their surface smoothness after covering a thin layer of UV oil, while binder jet prints touch always like sandstone.

Binder jet sandstone has some advantages over PolyJet resin, such as:

- Lower cost: Binder jet sandstone is cheaper than PolyJet resin because it uses less expensive materials and does not require support structures. PolyJet’s printing cost of the same model could be the double of Binder Jet printing.

- Larger build volume: Binder Jet can print larger objects than PolyJet because it does not have limitations on the size of the build platform.

- Eco-friendlier: Binder Jet sandstone is more environmentally friendly than PolyJet resin because it does not use toxic chemicals or generate waste materials.

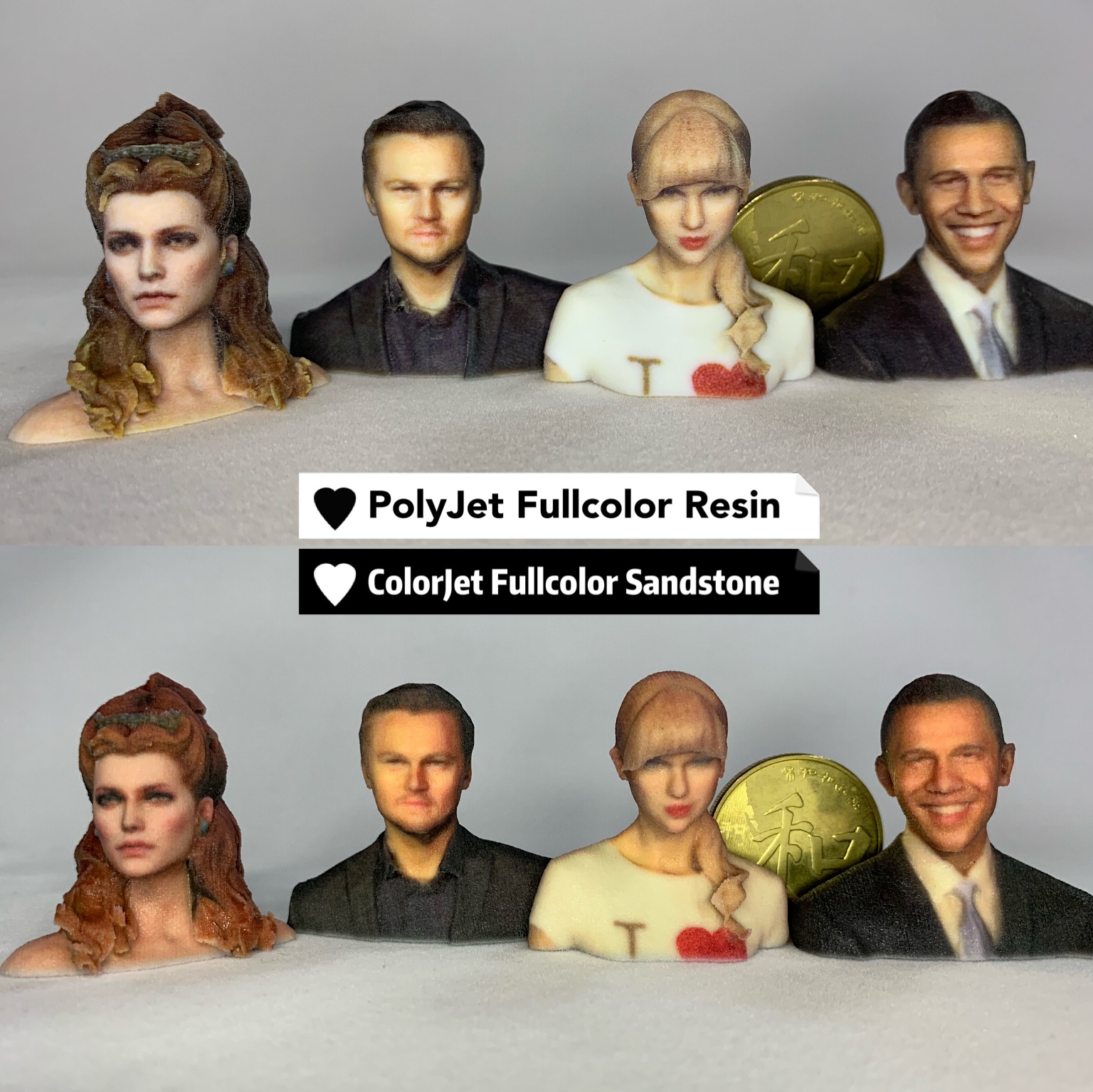

Cases: PolyJet and Binder Jet Full-color Miniatures

We have printed the same 3D model using PolyJet and Binder Jet technology respectively. You can clearly see the differences in printing quality.

These PolyJet statues are not covered in UV oil so it has a granular surface, similar with Binder Jet ones. With UV oil coating it would touches smooth and even.

PolyJet statues are in brighter and lighter colors, while Binder Jet statues are more reddish and darker.

The details of eyes and mouth and other features could be clearly seen on the PolyJet statues, while the features on Binder Jet statues are blurred.

In conclusion, both PolyJet resin and binder jet sandstone are 3D printing technologies that can produce colorful 3D prints with high quality. However, they also have some trade-offs that may affect their suitability for different applications. Therefore, users should consider their needs and preferences before choosing between them.

FacFox has years of experience in providing Binder Jetting and Polyjet 3D printing services to customers across various industries. They have a large fleet of machines and skilled engineers who can ensure your parts meet your specifications and expectations. Also, we can offer competitive prices and fast turnaround times.

To get started with your Binder Jetting or Polyjet 3D printing project, simply send your files to info@facfox.com and get an instant quote. FacFox will take care of the rest and deliver your parts to your doorstep. Don’t miss this opportunity to work with one of the best 3D printing service providers in the market. Contact FacFox today!