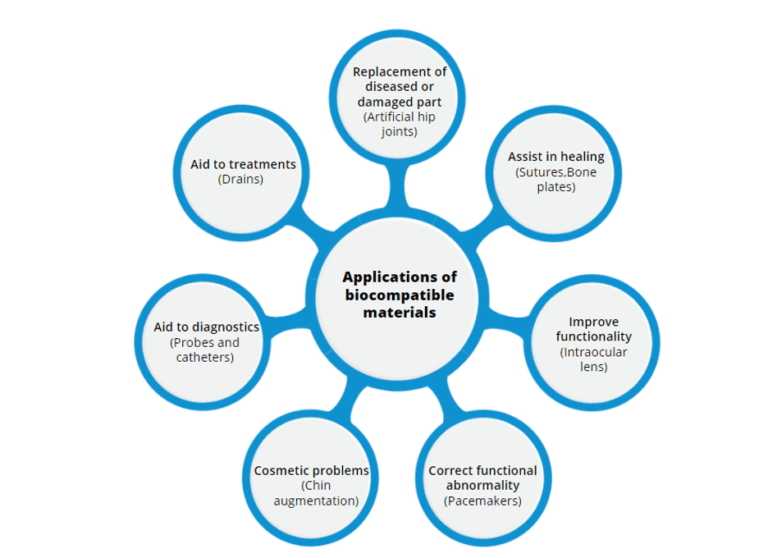

Biocompatible 3D printing uses biocompatible materials or biomaterials, which are natural or synthetic materials that can function in close contact with living tissue or even substitute a part of a living system. Biocompatible materials are designed to interface with biologically active systems for evaluating, treating, augmenting, or substituting any tissue, organ, or function of the body.

For example, biomaterials are used for joints, sutures, bone plates, and medical devices such as dentures, hearing aids, pacemakers, etc. A biomaterial that is used in making implants should contain some important desirable properties for long-term usage in the body without being itself rejected.

Material regulations

ISO 10993 (the international standard for device testing) provides guidance on how biocompatible materials can be used and tested as part of wider risk management and risk-reduction strategy. For example, these tests assure that the materials are not toxic or that they don’t cause skin irritation. Here you can find detailed guidelines on ISO 10993 regulations.

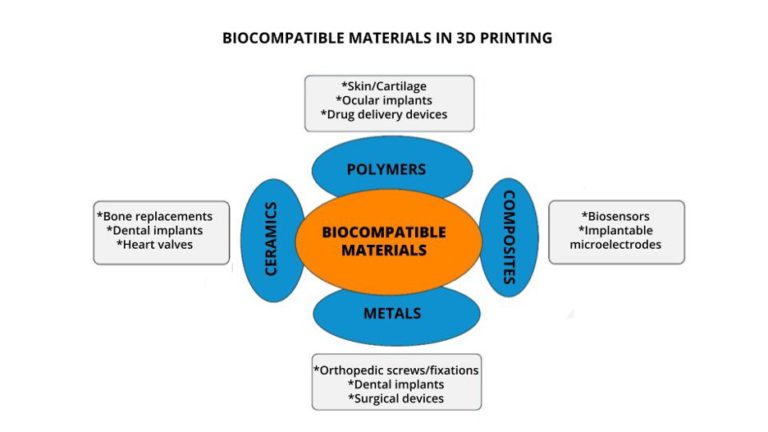

3D printing of biocompatible materials

Most 3D printing technologies can effectively use biocompatible plastics, elastomers, and metals for prototypes and functional parts. Compared to other manufacturing technologies, 3D printing of biocompatible materials provides better possibilities in terms of complexity and customization, which is very important for the medical industry. For example, a hearing aid that is generally available in the market may not fit a particular ear comfortably. In such cases, it’s viable these days to custom print those according to the ear dimensions.

Biocompatible 3D printing material options available at FacFox

Polyamide 12 (Nylon PA)

This is a highly versatile lightweight, corrosion-resistant, and chemical-resistant material. It is also tough and flexible with high tensile and impacts strengths. Nylon PA12 can be sterilized using ethylene oxide, chemical, gamma irradiation, gas plasma, and steam autoclave. It is printed using MJF, SLS, and FDM 3D printing. As a medical-grade material, Nylon PA-12 is an ISO-10993 certified and tested USP Class I-IV. It is commonly used in prosthetics and intramedullary rods.

Silicone (Sil 30)

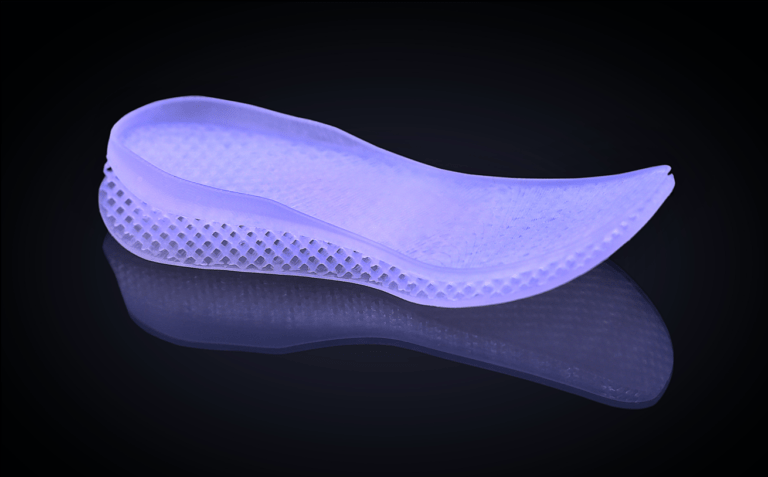

Silicone 30 is a heat-resistant, tear-resistant, and highly flexible biocompatible elastomer. It is commonly used in the manufacture of wearables with skin contact, such as respiratory masks. It complies with ISO 10993-5 and 10993-10. Silicone can be printed using Carbon DLS 3D printing.

CE 221

Cyanate Ester (CE 221) is known for its rigidity, high temperature, and chemical resistance. It is tested in accordance with ISO 10993-5 and is biocompatible. It is sterilized with steam autoclave, ethylene oxide (EtO), gamma irradiation, and electron beam. They can be used in making e.g. catheters and syringes.

EPX 82

Epoxy 82 is biocompatible and has good chemical, thermal, and UV stability – making it a diverse and versatile material for a wide array of applications. Its impact and heat resistance also allow for temperature cycling durability making it suitable for continuous use between varying temperatures. Its high resolution also allows for precise and accurate designs. It is tested against toxicity and irritation according to ISO 10993-5 and -10 and is sterilized using steam autoclave, ethylene oxide (EtO), gamma irradiation, electron beam. It is printed using Carbon DLS 3D printing.

RPU 70

Rigid polyurethane 70 is a material with high-strength, functional toughness, and high ductility. It can be 3D printed with Carbon DLS 3D printing, it complies with ISO 10993-5 and 10993-10 and is biocompatible. It is sterilized using steam autoclave, ethylene oxide (EtO), gamma irradiation, electron beam.

FPU 50

FPU 50 is a semi-rigid material with built-in elasticity that makes it resistant to abrasion, fatigue, and impact. FPU 50 is biocompatible and passed the requirements for biocompatibility according to ISO 10993-5. It can be sterilized using ethylene oxide (EtO), gamma irradiation, electron beam and is compatible for medical usage. It is printed using Carbon DLS 3D printing.

True Silicone

True Silicone is the only 100% pure silicone material available for 3D printing. It allows you to produce high-performance biocompatible 3D prints in 4 various Shore hardness options (A20, A35, A50, A60). True Silicone complies with ISO 10993 standards. The material is now extensively used in the fields of industrial, personal, and medical products. This material can be printed using Stereolithography (SLA).

ABS M30i

ABS M30i is another widely used thermoplastic in the medical industry. In addition to being biocompatible, it is also sterilizable using gamma irradiation, ethylene oxide, and gas plasma. ISO certified and USP Class I – IV, this material is often used to produce medical equipment and detailed anatomical models. It may also be used for prosthetics. ABS M30i is tough and has high tensile and impact strengths. It is printed using FDM.

PC ISO

This material is commonly used to create molds, prototypes, and custom surgical guides. While PC ISO has a lesser quality finish than Nylon PA12, it is strong and heat resistant with high tensile strength. PC ISO is also biocompatible, albeit short-term, and can be sterilized by gamma irradiation and ethylene oxide. PC ISO is printed via FDM.

Polyetherimide (ULTEM 1010)

Compared to other FDM thermoplastics, ULTEM 1010 is one of the strongest and most resistant to heat and chemicals. It is also highly biocompatible and can be sterilized using gamma irradiation, ethylene oxide, gas plasma, and steam autoclave. ULTEM 1010 is used to print surgical guides, prototypes, and prosthetics.

Stainless steel (17-4PH)

Stainless steel is a high-strength metal that is biocompatible and can be sterilized via various methods. However, its corrosion resistance is short-term, making it less preferable than titanium and cobalt chrome, especially for implants. This material is great for surgical tools and temporary implants. It can be printed by using direct metal laser sintering technology (DMLS).

Conclusion

Additive manufacturing paired with biocompatible materials provides great possibilities for the production of medical devices, implants, and personal wearables. Using FacFox’s on-demand 3D printing services, you can get the required amount of biocompatible 3D prints in up to 3 days. Just upload your CAD models and choose the required manufacturing options.