This is a guest publication by Robert Henzel, PhD Student from Stuttgart University. His academic research focuses on the concept of Cloud Manufacturing. FacFox supported Robert’s study by providing qualitative information and allowing the research team to contact FacFox customers.

Background of Manufacturing Development

Brief history of production theories

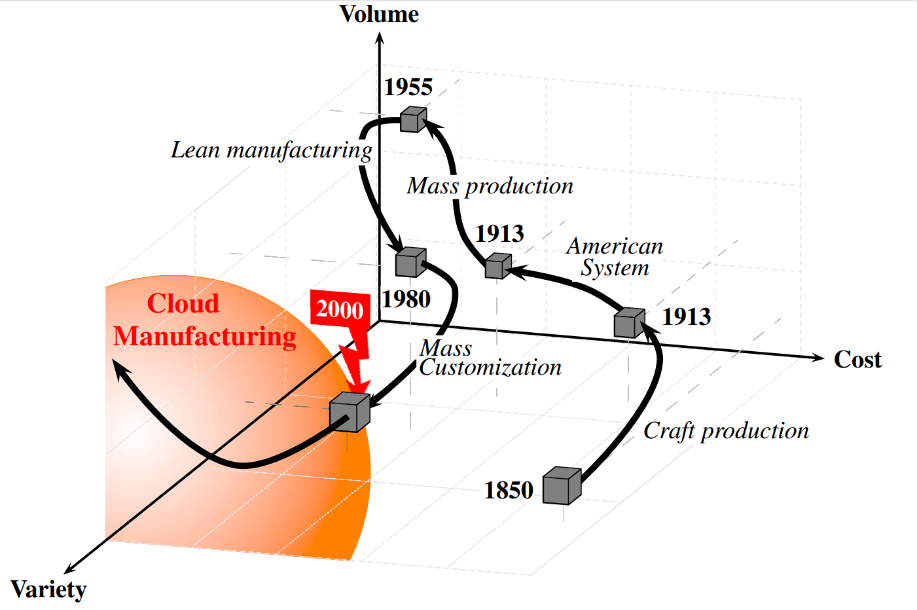

The manufacturing industry has been evolving since decades. One of the ways to clearly see in what directions the manufacturing concepts have been moving is to look at the manufacturing concepts from the perspective of three dimensions: “Cost”; “Variety” and “Volume”.

If we take a look at what factors played a more significant role in what period of time, we can see that some periods required lower cost, some – higher volumes. The manufacturing industry is now confronted with the ultimate goal of reducing costs, increasing volume whilst providing higher variety – as the market simply demands it.

Birth of Cloud Manufacturing and novelty

The concept of Cloud Manufacturing (CMfg for short) was developed as a novel production paradigm to meet all these market needs. The actual timing of the development of this concept was not random, but it happened because of the development of the internet and information technology.

Honoring those first pioneers, Goldhar and Jelinek were the first persons who formulated the idea of Manufacturing-as-a-Service in their paper “Manufacturing as a service business: CIM in the 21st century”, which can be treated as the underlying starting point for CMfg. Important to note, CMfg is not “old wine in new bottles” but rather a novelty.

What is Cloud Manufacturing?

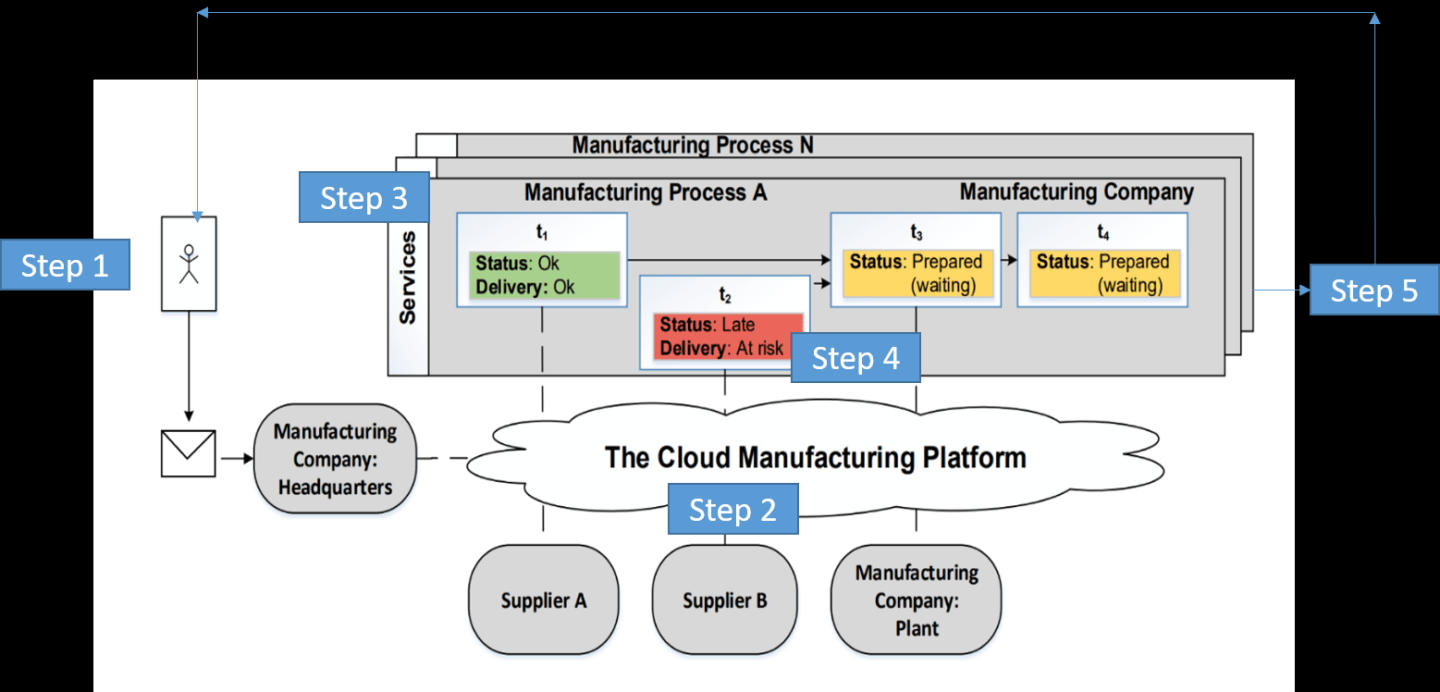

The concept of Cloud Manufacturing can be explained if we walk through the five-step process of ordering custom parts.

Vivid explanation of the corresponding process steps within the Cloud Manufacturing principle

Step 1: A client submits a specific manufacturing order into a Cloud Manufacturing platform.

Step 2: In this Cloud Manufacturing platform, there is a number of different suppliers (“Supplier A, Supplier B, or it can be even a specific plant from the same company which submitted the order”). So, Cloud Manufacturing relies on the production network, which can be based not only on the in-house machines, but also on the external partners.

Step 3: As soon as the order is placed, the Cloud Manufacturing platform constructs a specific manufacturing process which is aimed to accomplish the manufacturing task. For example, some of the parts can be produced in one place, others in a different place and post-processed in the third place. As a result, the logistical and manufacturing processes are not always identical. Figure 2 shows the multitude of possible manufacturing processes (N number of manufacturing layers).

Step 4: The platform detects the possibility of late delivery on a manufacturing step for a given customer order (t2 in the figure). Whereas the original manufacturing process ‘A’ was scheduled as follows: t2 → t3 → t4 (t2 was treated formerly as the first manufacturing step), the CMfg-platform changed the value-chain now into: t1 → t3 → t4. Hence, the manufacturing step at risk (t2) is eliminated and a new value-chain is constructed.

Step 5: Finalizing the manufacturing task, the corresponding logistics of materials and the actual processing of specific manufacturing steps is flowing according to the just constructed new value-chain. Lastly, the finalized product will be delivered to the customer.

Gap between theory and practice

This is, however, a theoretical look at the concept. In order to realize its actual potential, the industry still needs to develop further.

For example, there is a problem of a missing standardized communication across different machinery equipment from different providers and different corresponding information systems. In order to enable the full potential of Cloud Manufacturing, the information and data flow has to be integrative and seamless. Such integrations can boost Cloud Manufacturing even further and make it possible to connect instant quoting software directly with the network of machines.

Quo Vadis Cloud Manufacturing?

Speculations about Cloud Manufacturing market evolution

There is an academic research that makes it possible to assess the development of Cloud Manufacturing. Liu et. Al. (2019) [3] are expecting a multi-stage development, according to the following structure:

- Phase 1: “Preliminary implementation”

- Phase 2: “Relative complete implementation”

- Phase 3: “Complete implementation”

- Phase 4: “Full implementation”

In Phase 1, only a few types of resources (e.g. CNC machines, CAD software, etc.) are aggregated into a Cloud Manufacturing platform and only basic simple functions and applications are provided thereby. According to their maturity model, this will gradually increase over time, up to Phase 4.

In Phase 4, all possible resources are aggregated into a Cloud Manufacturing platform and all necessary corresponding platforms and manufacturing services are provided. Thus, the actual theory of CMfg, implied by figure two, emerges in reality.

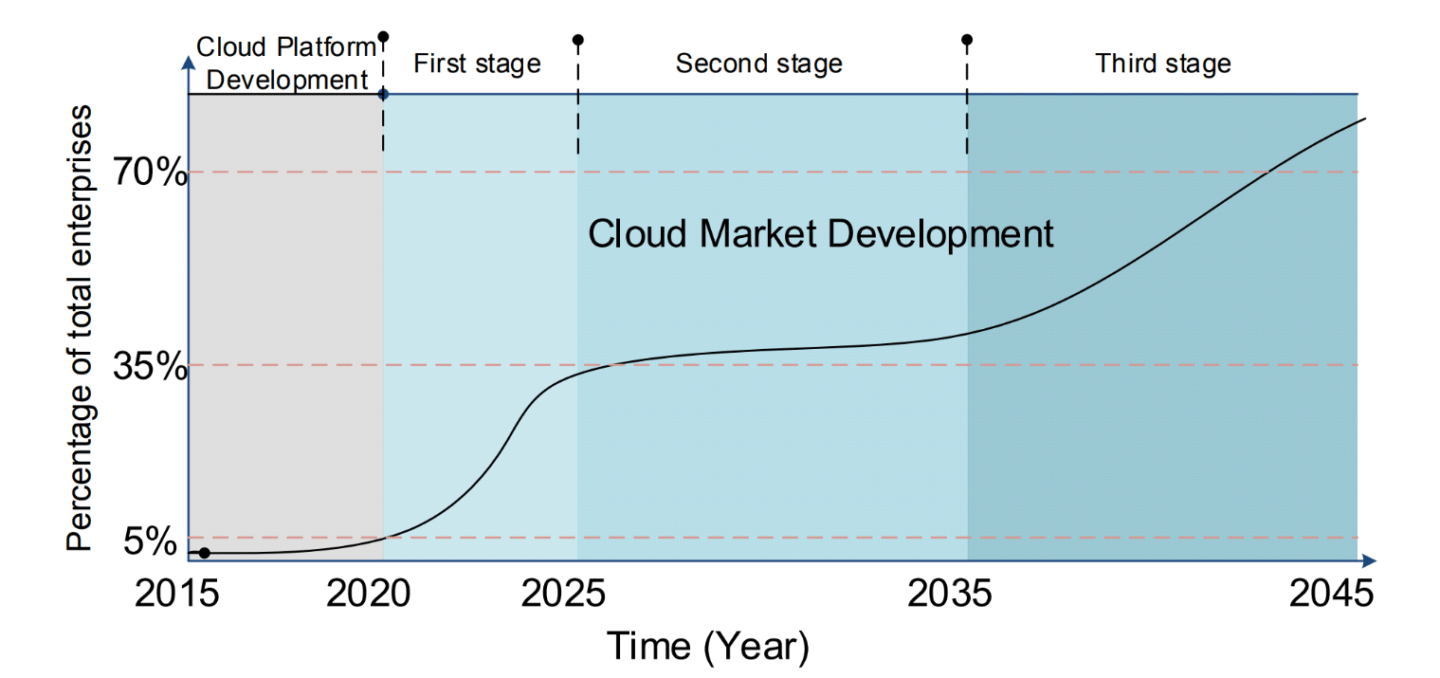

It is moreover interesting to mention the work from Wang and Peng (2013). They did a quite nice job by discussing the evolution of the CMfg market. They are using common economics models, like game theory and equilibrium analyses.

They are using a three-stage model to assume the development phases of the CMfg market: First stage, Second stage and Third stage. Each stage accumulates a larger percentage of the total manufacturing enterprises in the market. Their stages are very similar to the phases 1 to phase 4 described above.

So, where are we now? Actually, we are just at the beginning of this journey (Phase 1). When talking with field experts from practice and science, I got the overlapping rough estimation, that it will take up to an additional 15-20 years, until we are able to reach Phase 4.

An illustration about the Cloud Manufacturing market development

The following is the illustration of the speculation on the Cloud Manufacturing market from Wang and Peng, where the x-axis is denoting the respective year, whilst the y-axis is denoting the percentage of participating total enterprises.

Interestingly, their estimation of the third stage matches with my hypotheses the needed maturity time of 15-20 years.

Cloud Manufacturing landscape

There is already a significant number of early adopters in this field. Robin Dechant has been doing a great job overviewing this new market. I will now use two of his figures to illustrate the development in this field:

Cloud Manufacturing landscape’s evolution

The first obvious observation is the naming: whereas back in 2018 the concept of CMfg was largely treated as a somehow proxy term for 3D printing or prototyping, it has now changed to its actual core principle: Manufacturing-as-a-service (going finally back to Goldhar and Jelineks wording).

Moreover, even with consolidation taken part, the number of companies still rose by 34,4%, thus highlighting the growing market. In the additive manufacturing market, the trend is similar. Whereas in 2019 the number of companies was 171, it has risen to 240 in 2020 – showing an increase of 40,35%.

Observations on the current Cloud Manufacturing landscape

We can now conclude the following:

- A clear uptrend in this market, given by the sole number of companies in both, CMfg-market and AM-market

- Not yet saturated market (as many new companies keep on appearing)

- Rising interest in traditional manufacturing for this new type of manufacturing: big companies are trying to catch this trend by creating spin-offs or daughter startup companies; whilst employees from traditional manufacturing companies leave to establish a new business

- Partial consolidation has already taken place

- Still huge gap between theory and practice. Analyzing this landscape more deeply, we are still arguably in the Phase 1

Gartner hype cycle

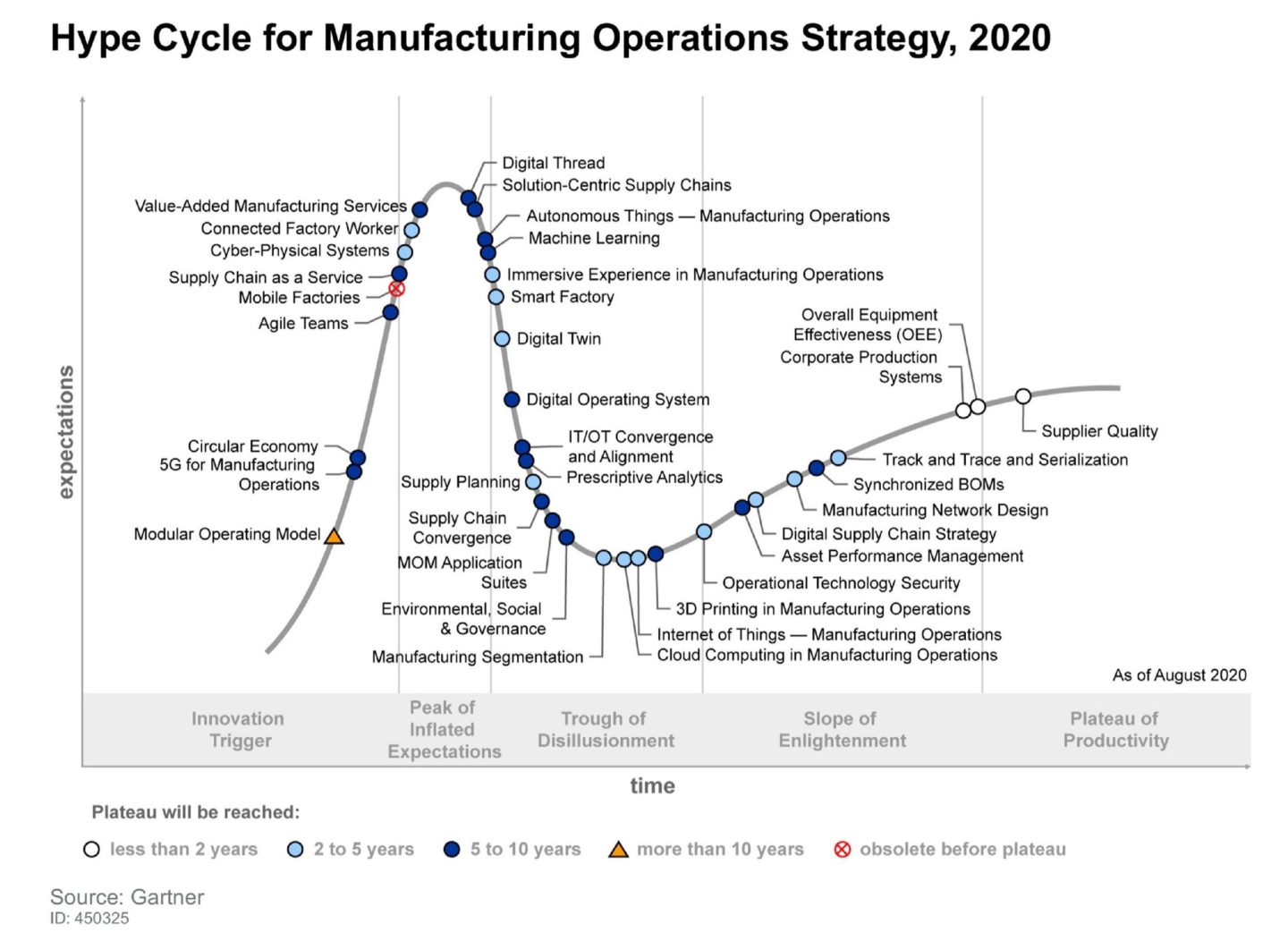

To conclude this section with a tangible analysis tool, let’s use the famous Gartner hype cycle. Its usage is quite common, in theory likewise in practice. The underlying hypotheses state that, for each and every new technology, the technology follows a specific path: ranging from a preliminary, rough market acceptance up to a bubble of hype.

Afterwards, it deleverages and finds something like a bottom of acceptance. Lastly it will be accepted and again, accumulated in attention.

I have marked the relevant things in red rectangles in the following figure six – we will assume (like stated in section two above) the term Smart Factory as a proxy term for CMfg.

According to the Gartner Hype Cycle, we are now right between the peak of expectations and the disillusionment area. The plateau of productivity will be reached in the next two to five years.

What Manufacturing industry can expect

After several years of research, I can suppose that there are many changes to expect in the future of manufacturing. I have grouped my thoughts in three main hypotheses, outlined in the following.

Major transformation of supply chains

First, traditional supply-chains will get affected quite harshly by CMfg – underlying inefficiencies will get erased systematically and by definition, the same is holding for not economically viable companies in this regard. CMfg will eventually get back after them. There will be some kind of survival of the fittest.

Regulations change in discrete and process manufacturing

Discrete manufacturing is already being challenged by process manufacturing, and is meant to be outperformed by manufacturing processes such as Cloud Manufacturing in the long term.

The manufacturing industry can be roughly divided into discrete and process manufacturing. In discrete manufacturing, one is assuming a duplication of identical products which are duplicated via an assembly line, whereas in process manufacturing, the finalized product cannot be dismantled into its raw materials.

Although the discrete manufacturing industry will be currently affected the most by the concept of CMfg, it is also applicable to process manufacturing.

For the development of Cloud Manufacturing within process manufacturing, it inherently needs more time, as there are strict regulations about workplace safety, manufacturing process safety and more general law standards in general. Although this may take more time in the short term, in the long term, this is actually in favor of CMfg, as a more naturally controlled place is fruitful to align with the CMfg principle. CMfg is naturally built for controlling.

This is due to the assumed complete information aspect or the knowledge management aspect of the underlying platform. Put differently, if there are any critical regulations or restrictions when manufacturing something specific, the CMfg is naturally able to process them accordingly and carefully – as it simply knows by given input!

It is even assumed that a more controlled area of subject is superior to deal with, as human errors are diminished systematically.

Real-world perception of current Cloud Manufacturing solutions

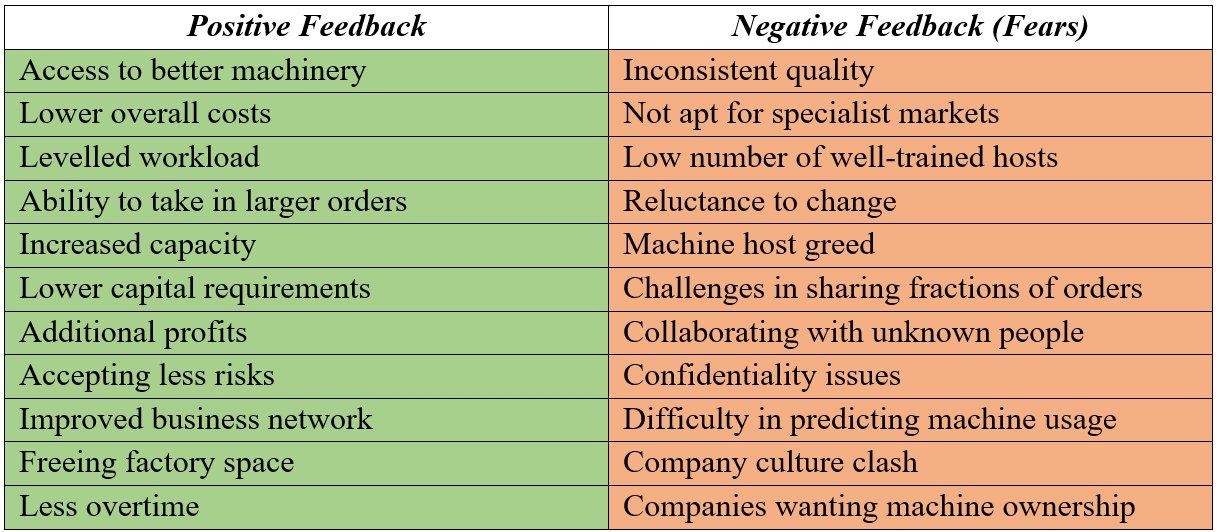

Finalizing this section, I will conclude with insights from a rare business-related CMfg paper from Charro and Schaefer [14] who analysed the perception of Cloud Manufacturing by potential machining providers. Leaving the science where it should belong, I will now stick to their final evaluation results of their model, given by the following table one:

Looking at the bright side of this beautiful cake, I will argue each of the negative aspects, trying to diminish them regarding the long-term viability of the concept of CMfg.

Here’re my thoughts on why the negative feedback should be considered rather as fear than real problems of Cloud Manufacturing”

“Company culture clash”, “Companies wanting machine ownership”, “Reluctance to change”, “Collaborating with unknown people” as well as “Machine host greed” are all rather subjective than objective statements. All of those are more or less completely diminished when taking into account the adoption of such factors as “Top management support”, “Compatibility” and “Trialability”. Once they are in place, I argue those rather subjective feelings will vanish. It is actually some kind of mind-process, which has to be aligned and developed.

For the remaining negative factors in the table, I argue, that those things will clearly be diminished when CMfg is maturing according to theory projections. Those remaining negative factors are basically all due to the yet unsophisticated status of CMfg, as this concept is in the development stage.

Conclusion

The industry market and its demand shifts. Various manufacturing paradigms were put forward to cope with this specific change. I assume that Cloud Manufacturing is the most promising model in this regard.

The theory is constantly developing at a faster pace; companies are being founded all over the world. The general acceptance for things like Cloud Computing also helps to accept cloud-based manufacturing paradigms like Cloud Manufacturing.

In another (although written in german) article of mine about Cloud Computing, where I was outlining the crucial and undeniable emergence of Cloud Computing, I claimed that it came here to stay. The future holds the same for CMfg. Either you accept the transformation in the manufacturing industry, or you do not. If one decides to ignore this transformation by default, they put their business at risk or put differently – it is actually very similar if one tries to ignore the internet in general: “It is just a trend, we do not need to follow each and every trend!” I believe it is NOT a trend. It is the destined future of manufacturing, ceteris paribus (all else equal).

If Cloud Manufacturing will not come sooner, then it will come later. Cloud Manufacturing is one promising way of acknowledging the trend change in the manufacturing market.

Finally, I will conclude with the title of one of the referenced papers: “Is Cloud Manufacturing a myth or the future of global manufacturing?”.In my opinion, it is the future of global manufacturing. Get on the train, folks!

Robert Henzel, PhD Student from Stuttgart University