When should you consider hollow your prints?

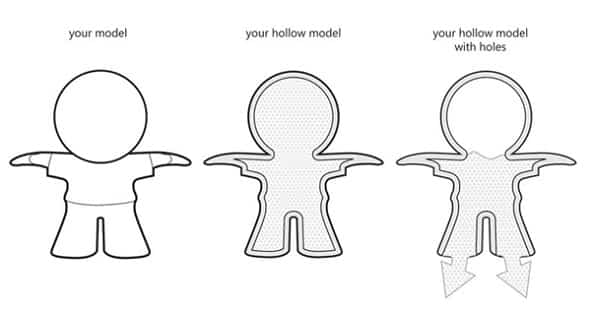

Hollow your 3D prints means that remove the inner material of a part but leave a shell. If you adopt a powder-based 3D printing technology, the hollow procedure can be applied.

Why should you hollow your prints?

Indeed, it does not only affect the cost and weight, but also the quality.

- This process is a good way to save material and less material means a clear reduction of the 3D printing cost of your part.

- It is also a good way to get a lightweight part! Hollowing is a really easy way to make your 3D parts lighter.

- As a hollowed model consists of less material, less heat is generated during the printing process. And less heat leads to a more stable process and reduces the potential risk of deformations in the printed objects.

A few rules and tips you need to know

- All the 3D design software allows you to hollow the model, and there are even some tools specifically meant for this purpose.

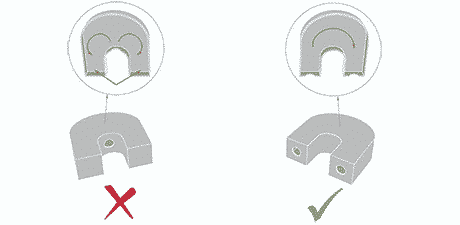

- A simple way to use these tools in order to hollow out your model is to select one of its surfaces and extrude it inwards

- You need at least two holes in your 3D model in order to remove the excess powder trapped inside your part during the cleaning process.

- If you hollow your part manually, you should ensure that the holes are at least 5 mm in diameter, or it will be hard for us to remove the powders.

- Place the holes on surfaces that will not be visible, such as at the bottom of the 3D models.

- There should be quite some distance between the two (or more) holes, letting the powder circulate inside the part.

Can all 3D models be hollowed?

It depends on its size. If your objects are too thin or too small, they cannot be hollowed.

These two types of objects require ample materials and have no excess powders. Besides, they are too fragile and vulnerable to be hollowed.