In this article, we will focus on how essential is the 3D printing resolution and how it affects your 3D models. What exactly is 3D printing resolution, how to check it and how it will influence your project? Let’s find out!

What does 3D printing resolution mean?

3D printing resolution is very important to check before you upload your 3D model for 3D printing. When it comes to Additive Manufacturing, the resolution depends on the layer thickness.

However, this is not the only factor you have to keep in mind while designing your parts. Despite that, the layer thickness of some materials can be as little as 28 µm, it doesn’t mean such a thin layer will be solid enough on its own.

Therefore, it is crucial you also check minimum details and engraving restrictions. We listed all the important information for you below.

Layer thickness

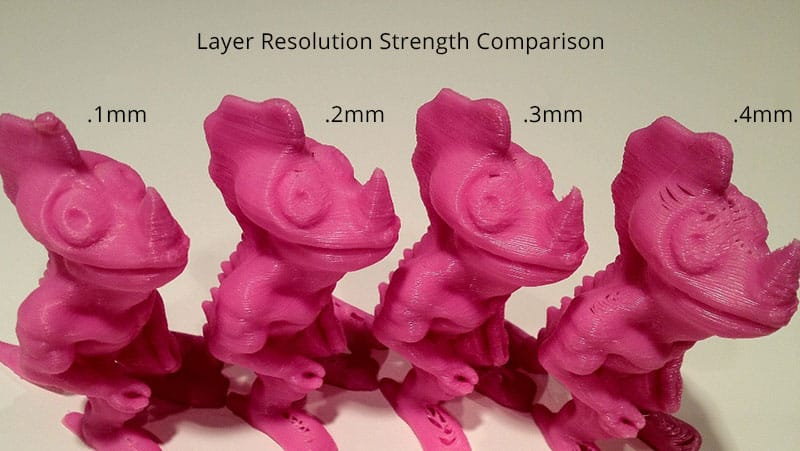

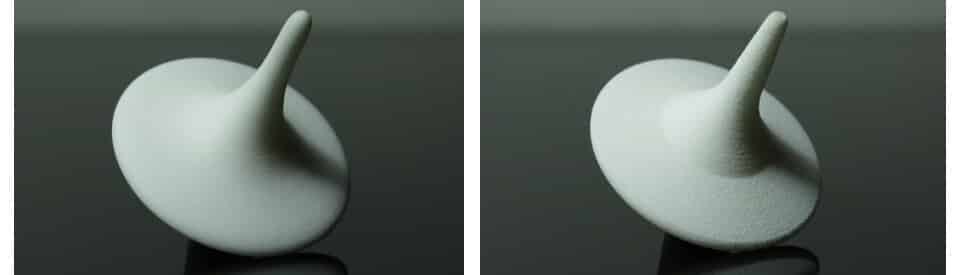

As you know, 3D printing is based on producing your model layer by layer. While desktop printers have come a long way, it is still sometimes tricky to get a very smooth surface.

And so, using industrial 3D printers might be the answer. Some machines are even capable of producing layers as small as 0.025 mm! To comparison, average hair is 0.18 mm thin.

Layer thickness is explained in micrometers (µm). 100 µm is equal to 0.1 mm. Within each 3D printing technology, the materials can have different layer thicknesses as they are used by different 3D printers.

Under the picture of the complex structure produced with Brass, we prepared a table with layer thicknesses of all of our materials.

Minimum detail

The amount of minimum detail is very important to keep in mind when designing for any 3D printing technology. The minimum detail depends on the technology, as the smaller the layer thickness the more accurate will be the detail.

If you don’t respect this value, your 3D model will simply break or the layers won’t be solidified properly.

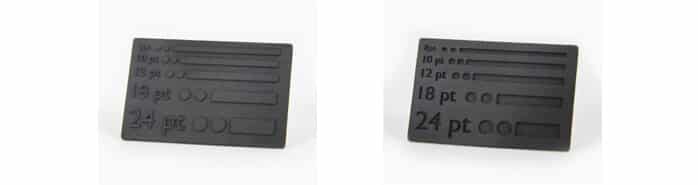

Minimum Engraving

Engraving is another interesting possibility of 3D printed parts; however, if the minimum value should not be respected, the engraving will not be visible.

We recommend making the engraving as deep as possible. There is a possibility that particularly fine engravings will not be visible as the carving can get filled with leftover powder.

If the engraving is not made to respect the minimum value, the powder won’t be removable. To ensure a better powder removal (thus better detail visibility), the width of your details must be at least as big as depth.

Prepare the perfect 3D model

Make sure your 3D model is well designed for 3D printing.

Let’s say you want to produce a 3D printed enclosure. Your model should be designed according to the circuit board and the ports for connecting cables. You should choose robust, but still somewhat flexible material so you can include assembly solutions in your design, which eliminates tooling and saves time. After deciding on the material, check all the essentials such as layer thickness, minimum detail, and in this case, the minimum thickness of the wall. Each of our materials has a material page with all the essential information.

Don’t worry if you don’t own a 3D printer, you can simply upload your design to our website for 3D printing! Our automated tool will also check if there are weak points of your design and allow you to choose the best orientation if it’s necessary. Don’t wait any longer and start 3D printing today!