The support structure is one thing you should take into account when designing a 3D model. It has been a barrier for players who newly enter this industry.

No worry. In this article, we will include:

- When do you need the supports

- How to choose from different types of support

- How to remove them

- The disadvantages of using supports.

When to use supports?

Rule 1: It depends on which 3D printing technology you use.

Firstly, you need to know what 3D printing technology you plan to use. The way 3D printers function determines each has technical restrictions.

FDM 3D Printer

It works by extruding filament layers successively, thus supports underneath are very useful to maintain the overhang structure of your part.

SLS/Jet Fusion 3D Printer

The powder-like materials will surround the printed part and act as supports and you don’t need to design extra supporting structures.

However, in the latest SLS metal printing process, supports are sometimes engaged and do not affect the printing quality.

Rule 2: It’s also determined by the complexity of your part.

- If your design contains overhangs, you have to figure out their tilt.

- If your overhangs don’t tilt more than 45°, most FDM printers will be able to print them properly.

- If angles exceed 45°, you might need to use supports or else your overhangs are likely to sag.

- If a part of your design bridges a gap between two elements and the length of it exceeds 5mm, you will need a support structure to fill the gap.

Different types of 3D printing supports

The 3D printers you own will lead you to choose suitable supports for your designs. FDM printed parts can use the lattice type and tree type supports. Having more than one print head is necessary for using soluble supports.

Anyway, the thumb rule is: consider the ease of removal before pick the best supporting structure.

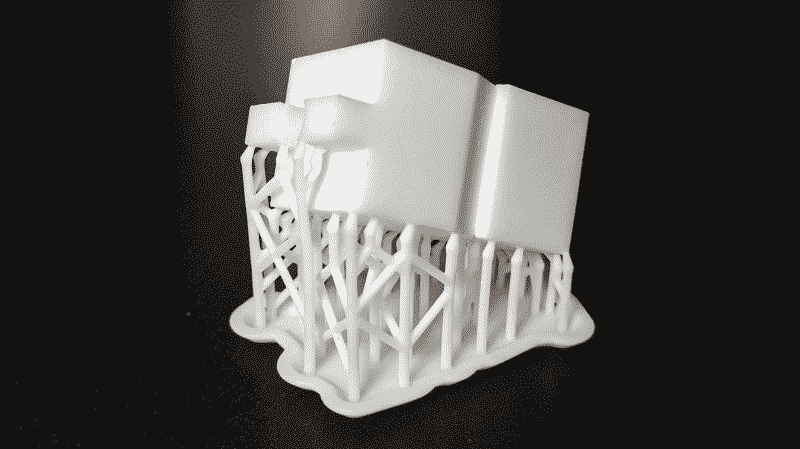

The lattice type

- It can be used to build columns and hold parts steady.

- It’s especially effective with steep overhangs.

- It can be generated fast and has good compatibility with most 3D prints.

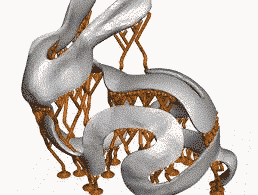

The tree type

- It starts with trunks and evolves in thin branches as they reach the model.

- It’s useful when you just need partially supports.

- It suits for projects contains many non-vertical overhangs.

Soluble supports

- It’s applicable when you have a two-extrusion head printer. Soluble materials can be loaded in one extruder and be applied along with your printing material.

- Dissolvable supports are relatively expensive but can be washed away by soaking them in water. It is the best way to keep a nice surface finish without adding extra steps to your post-processing.

Remove the supports

With the knowledge that lattice, tree-type and dissolvable supports have different properties, the ease of removal isn’t equal.

The more supports, the more contacting area, the harder to remove, and the more likely your print will break during removal.

- The lattice structures support the surfaces completely, make it hard to remove.

- Support only on a few key areas, the tree type has fewer contacts with the object and is easier to be removed.

- The soluble support can be simply washed out. Convenient and neat.

There are some tricks for removal, like using pliers when you want to grab, twist and pull your supports off your part. If the supports are accessible and big enough, your fingers will be the best tool.

After removal, the next step is sanding and polishing. The workload is determined by how important is the effect of surface and how many marks are left by the supports.

The downsides of using supports

The disadvantages have been referred to in the above and summarized below:

- The supports imply some limitations about your design and printing process.

- It’s kind of difficult to remove the supports, and sometimes can lead to damage.

- The lead time is increased as printing and removal of the supports all take time.

- The cost of printing supports can be a big part, sometimes even accounts for 1/2 of the total cost.

The size and complexity will affect the printing time of supports themselves. Tree-shape supports can be quite demanding for your printer.

Removing the supports off your parts and cleaning them is tedious and time-consuming.

The steep overhangs make up for a big part of your design and you need to use lattice structures to support them, the half of your material can possibly fall into the creation of your supports.

Fortunately, there are multiple ways one can rely on to mitigate the impacts your supports might have on your design and on your wallet.

How to avoid using supports?

Some 3D slicers can help you optimize the integration of your supports.

When printing supports, you should balance the density & thickness & the cooling speed.

The more supports are exposed to high temperatures (and the longer it takes to cool off), the more they will stick to your part. Hence the colder they remain, the easier it will be to remove your 3D printing supports.

The density of your supports will also impact its temperature. Reducing the amount of material will help them release heat. If your overhang is long, heavy or especially steep, you might need to make your supports dense to prevent your part from sagging. But keep in mind that the denser and thicker your supports are, the higher goes the risk of damage when removing the supports.

These are parts of the support generation options 3D slicers can help you tweak. But before you get to change that, there are a couple of ways you can optimize your 3D printing support structures in your design.

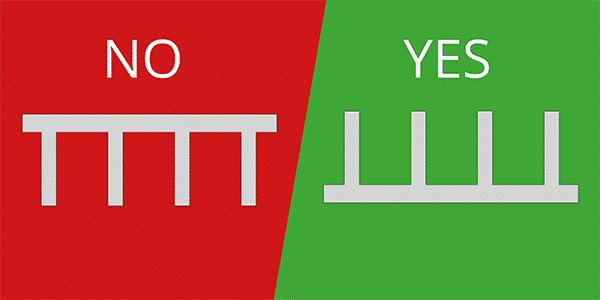

First of all, you have to figure out which orientation is the most consistent in terms of support generation. If you take a look at the two bridges, you will notice one difference: The second one is flipped upside-down, of course, but unlike the other one, it doesn’t need any support.

If you have already tried to play with the orientation of your part but believe it still requires too many supports, you may be able to tweak your overhangs. If for instance their angles are a bit too round and tilt over 45°, see if you can replace them using a single, less steep angle in your design. Another option you might want to try is to separate your design into two separate models. Going for this solution will definitely help you save on support materials, but in return, you will have to figure out how to reassemble your parts.