Creating small objects can be tedious, arduous and time-consuming. If you are bothering with making some tiny things by hand, why not try 3D printing?

In this guide, we will introduce some important factors which affect the 3D model and determine the quality of your final work.

Why choose 3D printing for manufacturing small parts?

There are several reasons to choose 3D printing over traditional manufacturing methods.

- It gives you absolutely new design freedom. You can reach a level of complexity that was not possible before.

- The 3D printed parts can be edited on the inside, giving you lightweight but durable structures.

- 3D printing also operates on layers and the thickness, serving you parts that are stronger, have better mechanical properties or more subtle and decorative characteristics.

Our top 5 Tips for 3D printing small objects

The keys for successful 3D printing small objects are simple: make every step correct and obey the rules.

In this chapter, we will go over our best tips and tricks to achieve the perfect 3D print. Starting with the correct STL files preparation, we will move on to the accuracy of your 3D models, then we will go over design guidelines and finally, we will talk about the layer height. We will also advise you on the best 3D printing technology for each type of material. Let’s get started!

Prepare with correct STL files

First of all, you need to make sure your 3D model is precise. You can’t have polygons, walls or faces missing as that will create a hole in your 3D model, or else it will not be printable.

The 3D model has to be realistic. After all, the 3D designs on your computer will become an actual object and it has to meet all the requirements under other technologies.

Your part has to actually be functional. In this case, 3D printing is no different from CNC or traditional foundry.

Remember to always check the design guidelines to assure your 3D models are well prepared for printing. It is crucial for the guidelines to be respected in order for the 3D prints to be accurate and precise.

Respecting the guidelines

Here are some essential things to keep in mind. They will help you to achieve the best results.

- Minimum wall thickness: It assures your model unbreakable, has minimum detail and clearance. Also to make sure your object will be as accurate as the 3D design on your computer.

- Maximum/ Minimum size: It is also worth mentioning. It depends on the size of the bed of the 3D printer and, depending on the 3D printing method, either the sintering laser beam or the nozzle size.

Think about the supports

Our aim is to print a small object as accurately as possible. Some parts of it might be thin and will require supports, but the supports should be removed in post-processing.

The models may not be thick enough either for you to gently take out the supporting system. If your 3D design is too thin, it will simply break during the support removal.

Accurate print: the layer thickness

Thickness can also be called layer height. Each 3D printing technology has a particular limit of layers, the 3D models might not meet your expectations as the layers of material will be visible.

Plastic and Resin 3D printing

As mentioned above, each additive manufacturing method has certain characteristics.

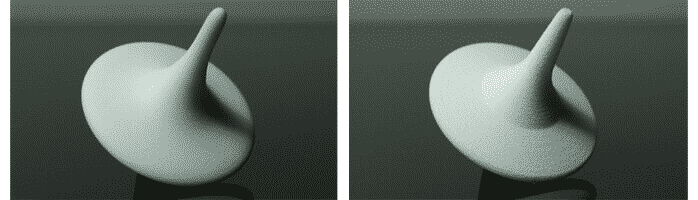

- PolyJet technology will provide you with some pretty impressive results at 28µm layer height with resin.

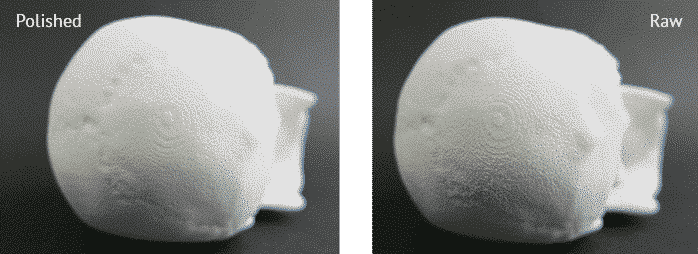

- SLS technology can make stronger parts with nylon, which still gives amazing results with the high definition option at 60µm and some very good finishes.

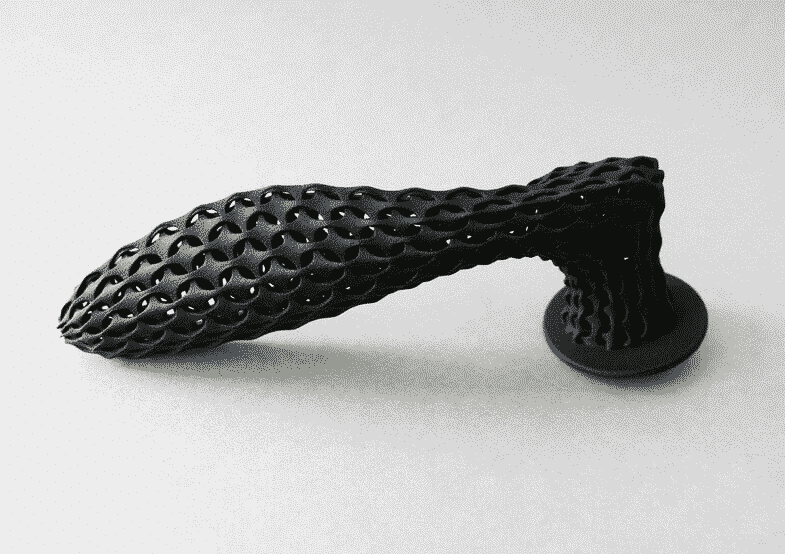

- MultiJet Fusion can provide with a layer thickness of 80µm with PA-12. The minimum wall thickness is 0.6mm, compared to 0.8mm of nylon.

Remember to make sure that your 3D models have the right thickness for the exact technology for us to be able to print them.

- PolyJet Resin: 28 µm layer height

- Nylon PA12: 60 µm (left) and standard 100-150 µm (right)

- Nylon PA11/12: Polished and Raw

- Nylon PA12: with different finishes at the same layer height

- MultiJet Fusion PA12: at 80 µm layer height

Metal 3D printing

As for Metal 3D printing, we offer 4 3D technologies: SLM, DMLS, Binder Jetting, and Casting.

The technologies differ in print time, temperatures of binding the metal, and the time to cool your 3D design.

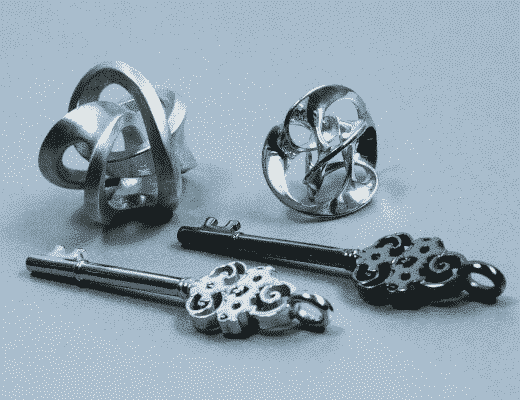

We also recommend you Casting for the small object. With a layer thickness of 25 µm, the object comes out precise and accurate, especially for little parts.

Make the right choice of metal to print objects perfectly.

- Silver 3D prints: layer thickness 25 µm

- Brass 3D prints: 25 µm layer height