Selective laser sintering (SLS) 3D printing is trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts.

In this extensive guide, we’ll cover the selective laser sintering process, the different systems and materials available on the market, the workflow for using SLS printers, the various applications, and when to consider using SLS 3D printing over other additive and traditional manufacturing methods.

What is Selective Laser Sintering 3D Printing?

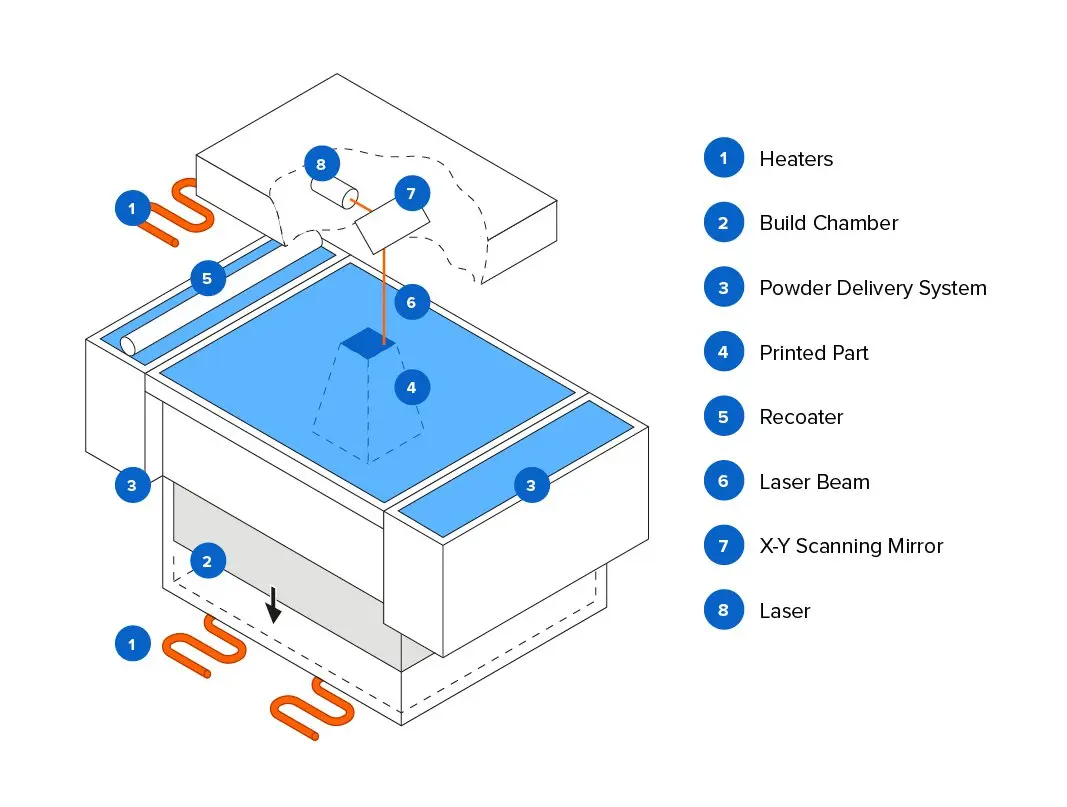

Selective laser sintering is an additive manufacturing (AM) technology that uses a high power laser to sinter small particles of polymer powder into a solid structure based on a 3D model.

SLS 3D printing has been a popular choice for engineers and manufacturers for decades. Low cost per part, high productivity, and established materials make the technology ideal for a range of applications from rapid prototyping to small-batch, bridge, or custom manufacturing.

Recent advances in machinery, materials, and software have made SLS printing accessible to a wider range of businesses, enabling more and more companies to use these tools that were previously limited to a few high-tech industries.

How SLS 3D Printing Works

- Printing: The powder is dispersed in a thin layer on top of a platform inside of the build chamber. The printer preheats the powder to a temperature somewhat below the melting point of the raw material, which makes it easier for the laser to raise the temperature of specific regions of the powder bed as it traces the model to solidify a part. The laser scans a cross-section of the 3D model, heating the powder to just below or right at the melting point of the material. This fuses the particles together mechanically to create one solid part. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. The platform then lowers by one layer into the build chamber, typically between 50 to 200 microns, and the process repeats for each layer until parts are complete.

- Cooling: After printing, the build chamber needs to slightly cool down inside the print enclosure and then outside the printer to ensure optimal mechanical properties and avoid warping in parts.

- Post-processing: The finished parts need to be removed from the build chamber, separated, and cleaned of excess powder. The powder can be recycled and the printed parts can be further post-processed by media blasting or media tumbling.

For the detailed workflow, see the “The SLS 3D Printing Workflow” section below.

As the unfused powder supports the part during printing, there’s no need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

Parts produced with SLS 3D printing have excellent mechanical characteristics, with strength resembling injection-molded parts.

A Brief History of SLS 3D Printing

Selective laser sintering was one of the first additive manufacturing techniques, developed in the mid-1980s by Dr. Carl Deckard and Dr. Joe Beaman at the University of Texas at Austin. Their method has since been adapted to work with a range of materials, including plastics, metals, glass, ceramics, and various composite material powders. Today, these technologies are collectively categorized as powder bed fusion—additive manufacturing processes by which thermal energy selectively fuses regions of a powder bed.

The two most common powder bed fusion systems today are plastic-based, commonly referred to as SLS, and metal-based, known as direct metal laser sintering (DMLS) or selective laser melting (SLM). Until recently, both plastic and metal powder bed fusion systems have been prohibitively expensive and complex, limiting their use to small quantities of high value or custom parts, such as aerospace components or medical devices.

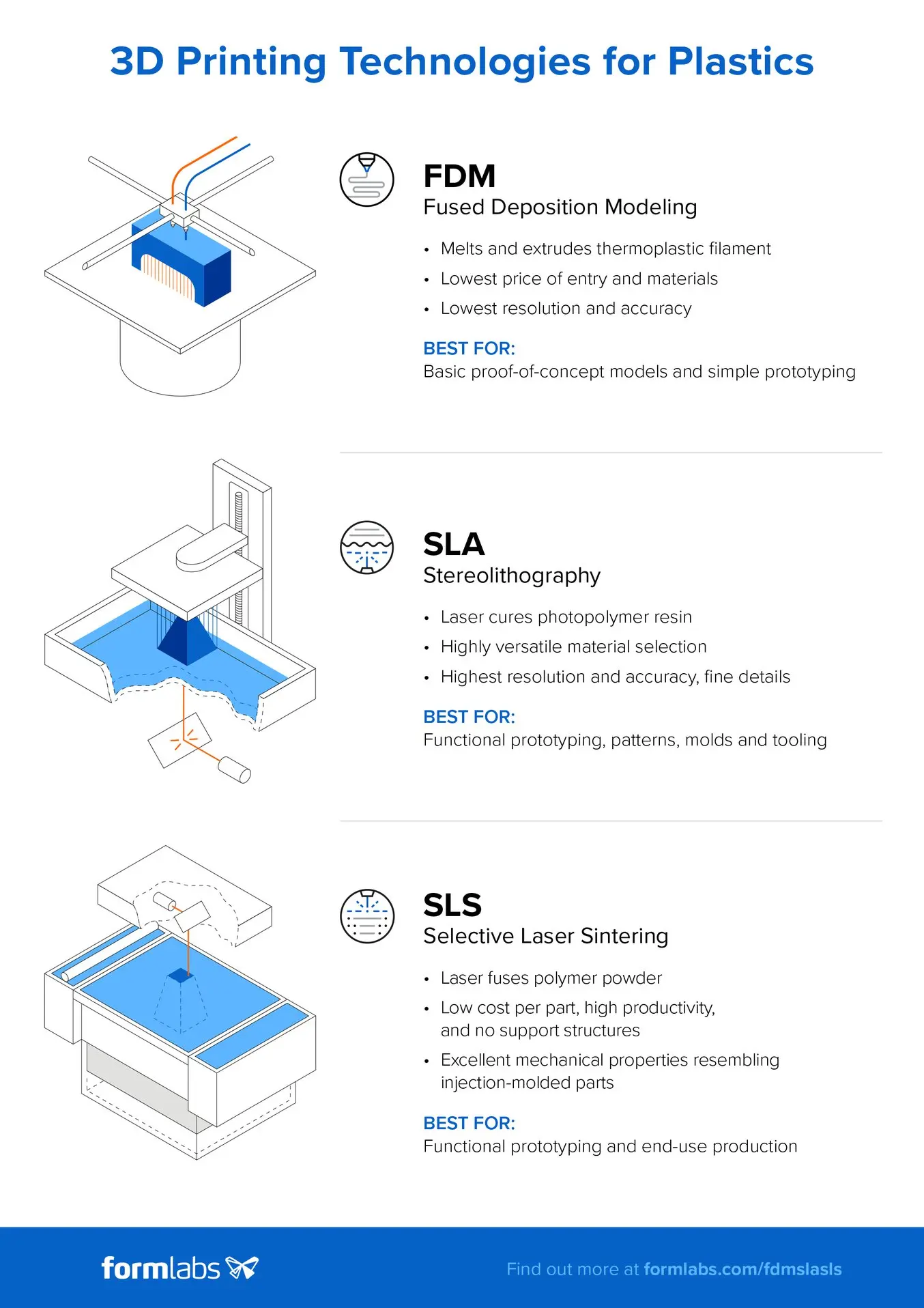

Innovation in the field has surged recently, and plastic-based SLS is now poised to follow other 3D printing technologies like stereolithography (SLA) and fused deposition modeling (FDM) to gain widespread adoption with accessible, compact systems.

Types of SLS 3D Printers

All selective laser sintering 3D printers are built around the process described in the previous section. The main differentiators are the type of laser, the size of the build volume, and the complexity of the system. Different machines use different solutions for temperature control, powder dispensing, and layer deposition.

Selective laser sintering requires a high level of precision and tight control throughout the printing process. The temperature of the powder along with the (incomplete) parts must be controlled within 2 °C during the three stages of preheating, sintering, and storing before removal to minimize warping, stresses, and heat-induced distortion.

Traditional Industrial SLS 3D Printers

Selective laser sintering has been one of the most popular 3D printing technologies for professionals for decades, but its complexity, requirements, and high price has limited their use to service bureaus and large enterprises.

Traditional industrial SLS 3D printing systems use a single or multiple high-power lasers. The printing process requires an inert environment–nitrogen or other gases–to prevent powder from oxidizing and degrading, which makes specialized air handling equipment necessary.

These machines also require special HVAC and industrial power, and even the smallest industrial machines take up at least 10 m² installation space.

With a starting price of around $100,000 that goes well beyond that for the full solutions, traditional industrial SLS has been inaccessible for many businesses.

Fuse 1: The First Benchtop Industrial SLS 3D Printer

Just like with other 3D printing technologies like FDM or SLA, lower cost, compact SLS systems have recently started to emerge on the market, but these solutions came with considerable trade-offs. These include lower part quality and complex, manual workflows resulting from the lack of post-processing solutions, which have so far limited their use in industrial and production settings.

The Formlabs Fuse 1 aims to bridge this gap and create its own category with the first benchtop industrial SLS 3D printer that offers high quality, compact footprint, and a complete, simplified workflow at a fraction of the cost of traditional industrial SLS systems.

The Fuse 1 uses a single laser and has a smaller build chamber that requires less heating. As the powder gets exposed to elevated temperatures for a shorter period of time, there is no need for inert gases and specialized air handling equipment. The lower energy consumption means that it can run on standard AC power without requiring specialized infrastructure.

The Fuse 1 features a patent-pending solution called Surface Armor, a semi-sintered shell that keeps the area around the parts evenly heated as they print, ensuring great surface finish, consistent mechanical properties, high reliability, and high refresh rates.

To offer a compact, contained ecosystem and end-to-end powder handling, the Fuse 1 also comes with the Fuse Sift, which combines part extraction, powder recovery, storage, and mixing in a single free-standing device.

Overall, benchtop industrial SLS 3D printing with the Fuse 1 offers a slightly smaller build volume compared to the entry-level traditional SLS systems, in return for a substantially smaller footprint, simplified workflow, and lower cost.

Comparison of SLS 3D Printers

| FUSE 1: BENCHTOP INDUSTRIAL SLS | TRADITIONAL INDUSTRIAL SLS 3D PRINTERS | |

|---|---|---|

| Price | Starting at $18,500 | $100,000-$500,000+ |

| Print Volume | Up to 165 x 165 x 300 mm | Up to 550 x 550 x 750 mm |

| Pros | Affordable High-quality parts High throughput Simplified workflow Small footprint Low maintenance |

Large build volume High-quality parts High throughput Multiple material options |

| Cons | Smaller build volume Limited material options |

Expensive machinery Large footprint Facility requirements High maintenance Requires a dedicated operator |

SLS 3D Printing Materials

The most common material for selective laser sintering is nylon, a highly capable engineering thermoplastic for both functional prototyping and end-use production. Nylon is ideal for complex assemblies and durable parts with high environmental stability.

SLS 3D printed nylon parts are strong, stiff, sturdy, and durable. The final parts are impact-resistant and can endure repeated wear and tear. Nylon is resistant to UV, light, heat, moisture, solvents, temperature, and water. 3D printed nylon parts can also be biocompatible and not sensitizing, which means that they are ready to wear and safe to use in many contexts.

Nylon is a synthetic thermoplastic polymer that belongs to the family of polyamides. Nylon 12 enables a broad range of applications and is a versatile general-use powder for SLS 3D printing. Nylon 11 helps fill the gap for prototyping and end-use applications that require higher ductility, impact-resistance, and the ability to withstand wear and tear without brittle failure.

Nylon 11

Ductile, strong, flexible material for when durability and performance are key.

- Impact-resistant prototypes, jigs, and fixtures

- Thin-walled ducts and enclosures

- Snaps, clips, and hinges

- Orthotics and prosthetics

Nylon 12

General purpose, versatile material with high detail and great dimensional accuracy.

- High-performance prototyping

- Small batch manufacturing

- Permanent jigs, fixtures, and tooling

- General SLS parts

SLS Nylon Material Properties

| NYLON 12 POWDER | NYLON 11 POWDER | |

|---|---|---|

| Ultimate Tensile Strength | 50 MPa | 49 MPa |

| Tensile Modulus | 1850 MPa | 1573 MPa |

| Elongation at Break (X/Y) | 11 % | 40 % |

| Notched IZOD | 32 J/m | 71 J/m |

| Heat Deflection Temperature (HDT) @ 0.45 MPa | 171 °C | 182 °C |

Nylon 12 and Nylon 11 are single-component powders, but some SLS 3D printers can also use two-component powders, such as coated powders or powder mixtures. Nylon composites with aluminide, carbon, or glass are developed to optimize parts for higher strength, stiffness, or flexibility. With these two-component powders, only the component with the lower glass transition point is sintered, binding both components.

The SLS 3D Printing Workflow

1. Design and Prepare the File

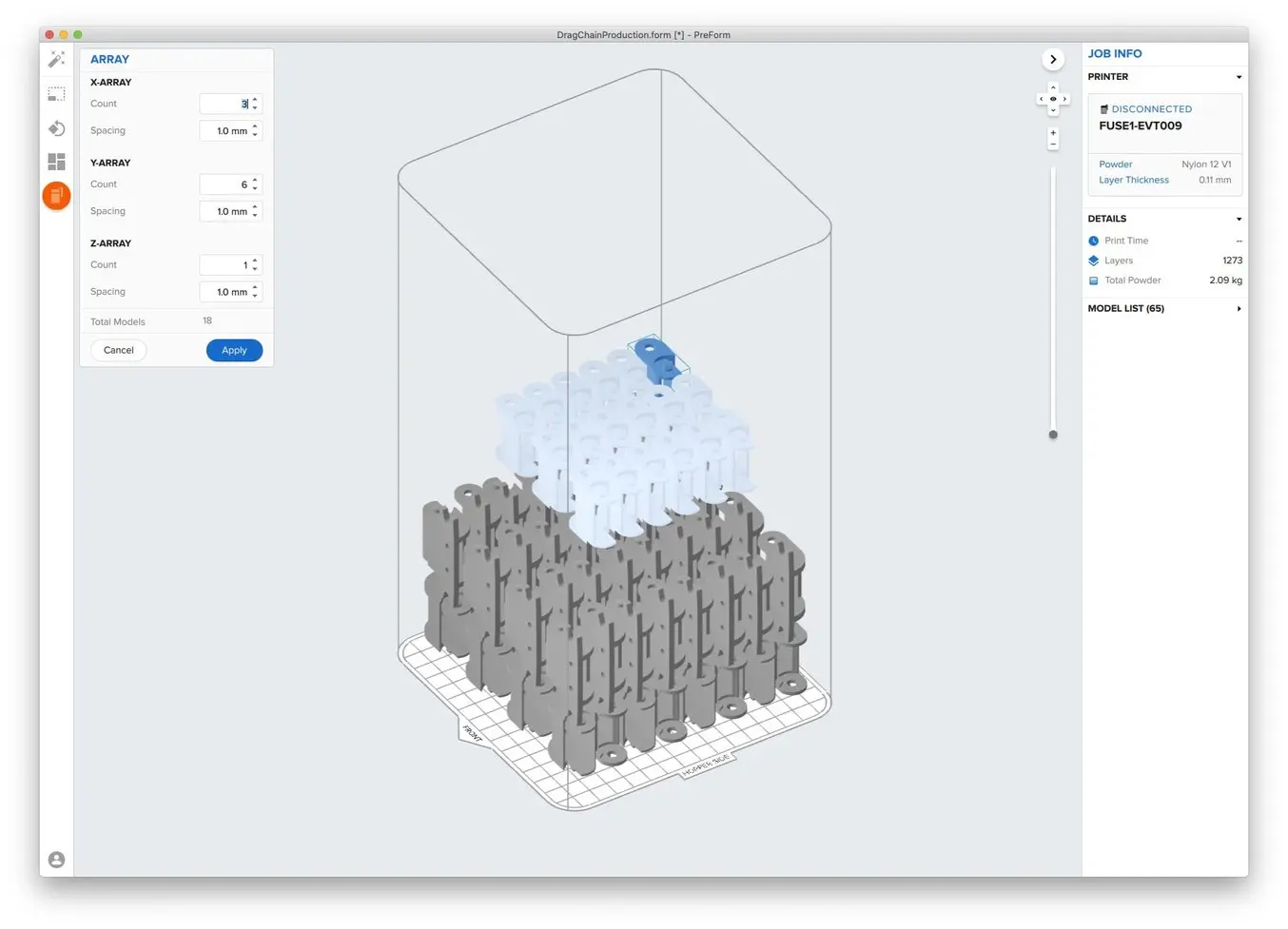

Use any CAD software or 3D scan data to design your model, and export it in a 3D printable file format (STL or OBJ). Each SLS printer includes software to specify printing settings, orient and arrange models, estimate print times, and slice the digital model into layers for printing. Once setup is complete, the print preparation software sends the instructions to the printer via a wireless or cable connection.

2. Prepare the Printer

The workflow for preparing the printer varies by system. Most traditional SLS systems require extensive training, tools, and physical effort to prepare and maintain.

The Fuse 1 reimagines the SLS workflow for simplicity and efficiency, with modular components to enable nonstop printing and end-to-end powder handling.

3. Print

Once all preprint checks have been completed, the machine is ready to print. SLS 3D prints can take anywhere from a few hours to multiple days depending on the size and complexity of parts, as well as the part density.

Once the print is finished, the build chamber needs to slightly cool down in the print enclosure before moving to the next step. After that, the build chamber can be removed and a new one inserted to run another print. The build chamber has to cool down before post-processing to ensure the optimal mechanical properties and avoid warping in parts. This may take up to half of the print time.

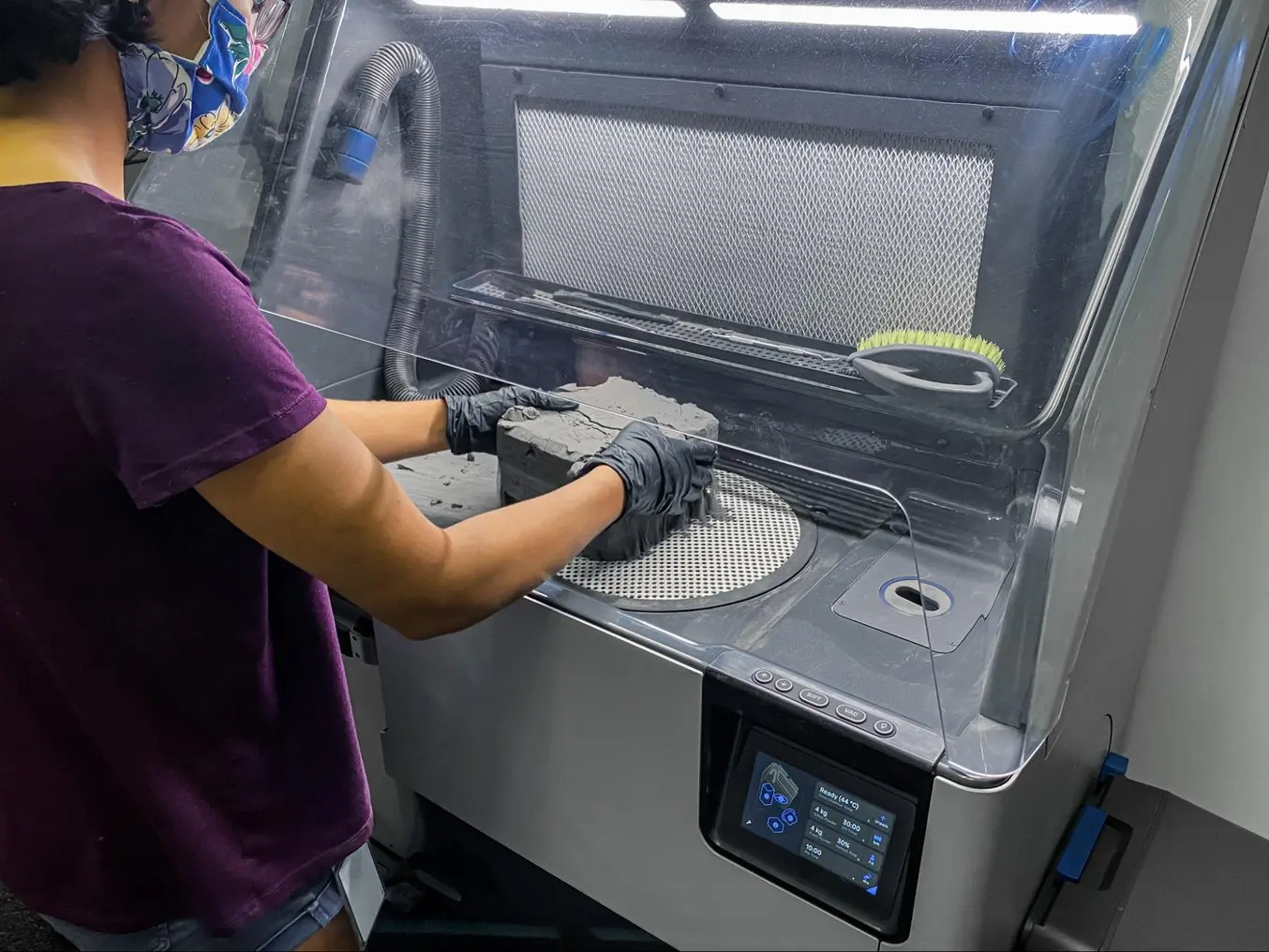

4. Part Recovery and Post-Processing

Post-processing SLS parts require minimal time and labor compared to other 3D printing processes. It is easily scalable and yields consistent results for batches of parts thanks to the lack of support structures.

After a print job is complete, remove the finished parts from the build chamber, separate them, and clean them of excess powder. This process is typically completed manually at a cleaning station using compressed air or a media blaster.

Any excess powder remaining after part recovery is filtered to remove larger particles and can be recycled. Unfused powder degrades slightly with exposure to high temperatures, so it should be refreshed with new material for subsequent print jobs. This ability to re-use the material for subsequent jobs makes SLS one of the least wasteful manufacturing methods.

A common theme in the SLS industry is to offer separate devices for reclaiming, storing, and mixing powder. In the Fuse 1 workflow, a single device, Fuse Sift, handles the extraction of parts and unsintered powder, as well as storing, dosing, and mixing of streams.

5. Additional Post-Processing

SLS 3D printed parts are ready to use after sifting. However, there are several other post-processing steps that you might consider for selective laser sintered parts.

By default, SLS 3D prints have a grainy finish. Formlabs recommends media blasting or media tumbling SLS parts for a smoother surface finish. Parts may be spray painted, lacquered, electroplated, and coated to achieve different colors, finishes, and properties, for example, watertightness (coating) and conductivity (electroplating). Formlabs SLS parts are dark in color, so they are not ideal for dyeing.

Why Choose SLS?

Engineers and manufacturers choose selective laser sintering for its design freedom, high productivity and throughput, low cost per part, and proven, end-use materials.

Design Freedom

Most additive manufacturing processes, such as stereolithography (SLA) and fused deposition modeling (FDM), require specialized support structures to fabricate designs with overhanging features.

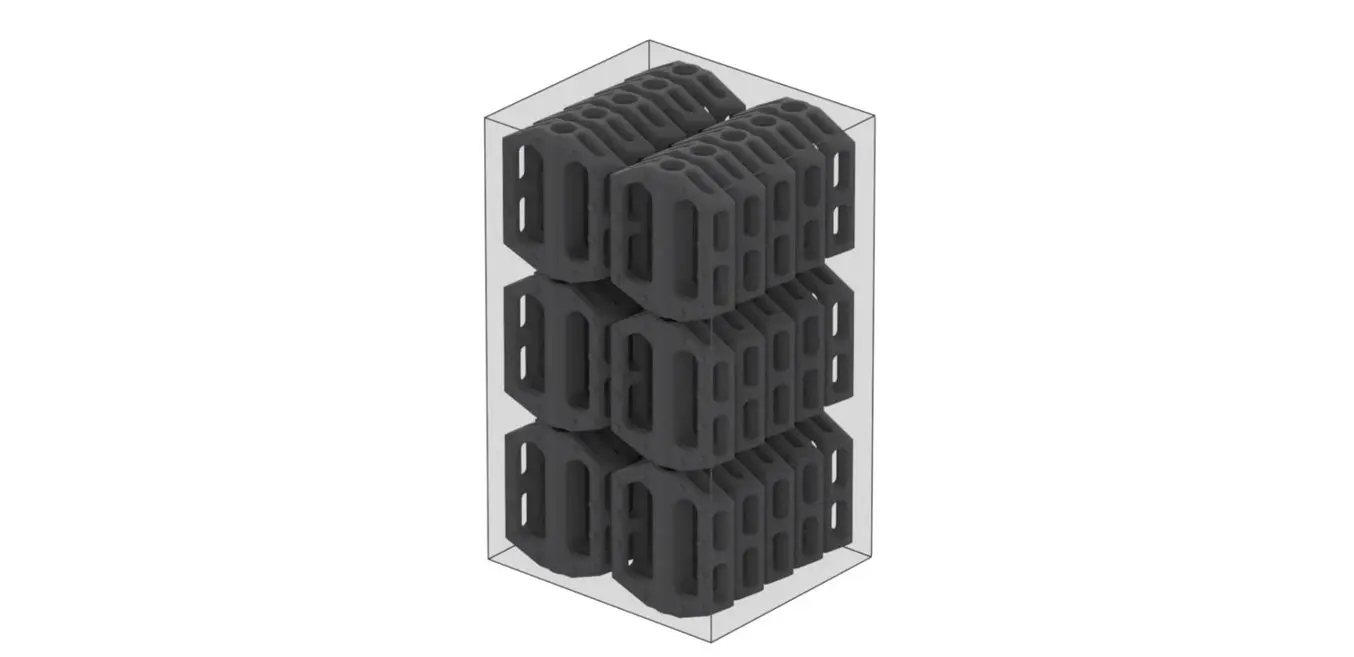

Selective laser sintering does not require support structures because unsintered powder surrounds the parts during printing. SLS printing can produce previously impossible complex geometries, such as interlocking or moving parts, parts with interior components or channels, and other highly complex designs.

Engineers generally design parts with the capabilities of the final manufacturing process in mind, also known as design for manufacturing (DFM). When additive manufacturing is used for prototyping alone, it is limited to parts and designs that conventional manufacturing tools can ultimately reproduce during production.

As selective laser sintering becomes a viable rapid manufacturing method for an increasing number of end-use applications, it has the potential to unleash new possibilities for design and engineering. SLS 3D printers can produce complex geometries that are impossible or prohibitively costly to manufacture with traditional processes. SLS also empowers designers to consolidate complex assemblies that would normally require multiple parts into a single part. This helps alleviate weak joints and cuts down on assembly time.

Selective laser sintering can take generative design to its full potential by enabling lightweight designs that employ complex lattice structures impossible to manufacture with traditional methods.

High Productivity and Throughput

SLS printing is the fastest additive manufacturing technology for functional, durable prototypes and end-use parts. The lasers that fuse the powder have a much faster scanning speed and are more accurate than the layer deposition methods used in other processes like industrial FDM.

Multiple parts can be tightly arranged during printing to maximize the available build space in each machine. Operators use software to optimize each build for the highest productivity leaving only minimal clearance between parts.

Proven, End-Use Materials

The key to SLS 3D printing’s functionality and versatility is the materials. Nylon and its composites are proven, high-quality thermoplastics. Laser-sintered nylon parts have close to 100 percent density with mechanical properties comparable to parts created with conventional manufacturing methods like injection molding.

SLS nylon is a great substitute for common injection molding plastics. It offers superior living hinges, snap fits, and other mechanical joints compared to any other additive manufacturing technology. It is ideal for functional applications requiring plastic parts that will last where parts produced with other AM methods would degrade and become brittle over time.

Competitive Cost Per Part

Calculating cost per part usually requires accounting for equipment ownership, material, and labor costs:

- Equipment ownership: The more parts a machine can produce over its lifetime, the lower the costs attributable to each individual part. Consequently, higher productivity leads to lower equipment ownership costs on a per-part basis. Given the fast scanning speed of the laser, the nesting of parts to maximize build capacity, and simple post-processing, SLS 3D printing offers the highest productivity and throughput of all plastic additive manufacturing techniques.

- Material: While most 3D printing technologies use proprietary materials, nylon is a common thermoplastic produced in large quantities for industrial purposes, making it one of the least expensive raw materials for additive manufacturing. As SLS 3D printing doesn’t require support structures and allows for printing with recycled powder, the process produces minimal waste.

- Labor: The Achilles heel of many 3D printing solutions is labor. Most processes have complex workflows that are hard to automate, which can substantially influence the cost per part. The simple post-processing workflow of SLS printing means less labor is required and the process is easy to scale.

An SLS 3D printer represents a substantial initial investment, but it can often recoup the initial investment even faster than smaller machines. Benchtop SLS significantly reduces this barrier to entry and also the per par cost for most applications.

Outsourcing production to service bureaus is recommended when your business requires 3D printing only occasionally, but it also comes with higher costs and long lead times. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes a week or even multiple weeks to arrive.

Reduced Product Development Cycles

Selective laser sintering enables engineers to prototype parts early in the design cycle, then use the same machine and material to produce end-use parts. SLS 3D printing does not require the same expensive and time-consuming tooling as traditional manufacturing, so prototypes of parts and assemblies can be tested and easily modified over the course of a few days. This drastically reduces product development time.

Given its low cost per part and durable materials, SLS printing is an economical way to produce complex, custom parts, or a series of small components for end products. In many cases, laser sintering is a cost-effective alternative to injection molding for limited-run or bridge manufacturing.

SLS 3D Printing Applications

SLS 3D printing accelerates innovation and supports businesses across a wide range of industries, including engineering, manufacturing, and healthcare.

Engineering

Take control of your entire product development process, from iterating on your first concept design to manufacturing ready-to-use products:

- Rapid prototyping

- Mockups of products for in-field customer feedback

- Functional prototyping

- Rigorous functional testing of products (e.g: ductwork, brackets)

Manufacturing

Own your supply chain and respond quickly to changing demands:

- End-use production

- Small batch manufacturing

- Production of novel mass customization consumer products

- Replacement part production, supply chain robustness

- Long-lasting, durable jigs and fixtures (e.g clips and clamps) and tooling

- Custom automotive or motorcycle parts, marine equipment, military ‘resupply on demand’

Healthcare

Manufacture ready-to-use, patient-specific medical devices in-house:

- Medical device prototyping

- Prosthetics and orthotics (i.e. limb replacements + braces)

- Surgical models + tools

- End-use parts (nylon 12 is biocompatible + compatible with sterilization*)

* Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.