We offer liquid silicone rubber (LSR) among our list of injection molding capabilities. LSR molding shares many similarities with conventional injection molding, but there are a few notable differences. Unlike thermoplastic resin, which is melted before injection, LSR is a two-part thermoset compound that is chilled, before being injected into a heated mold and ultimately cured into a final part. Since LSR is a thermosetting polymer, its molded state is permanent—once it is set, it can’t be melted again like a thermoplastic.

LSR has certain inherent characteristics. It is a strong, elastic material with excellent thermal, chemical, and electrical resistance. LSR parts also maintain their physical properties at extreme temperatures and can withstand sterilization. LSR is biocompatible so it works very well for products that have skin contact. Those benefits lend themselves well to automotive, medical and food appliance industries, typically in the form of seals, gaskets, valves, and cables.

Designing parts for LSR and thermoplastics are similar, but there are some LSR-specific guidelines to consider:

Dimensions

We allow for a maximum LSR part size of 12 in. (304mm) by 8 in. (203mm) by 4 in. (100mm) with depths no greater than 2 in. (50mm) from any parting line. Note that deeper parts are limited to a smaller outline. Maximum surface area is 65.5 sq. in. (422.6 sq. cm.) and maximum volume of part is 26 cu. in. (426 cc).

Wall and Rib Thickness

LSR typically fills thin wall sections with minimal challenges, and walls as thin as 0.012 in. are possible over smaller areas but down to 0.015 in. thick over larger areas, depending on the size of the wall and the location of adjacent thicker sections. Rib thickness should be 0.5 to 1.0 times the adjoining wall thickness. LSR is accommodating to variations in wall thickness and sink is almost nonexistent.

Shrink and Flash

The shrink rate on LSR is fairly high but is very consistent throughout the entire part with an expected tolerance of 0.025 in./in. LSR also tends to flash very easily during molding (in gaps as small as 0.0002 in.), which Protolabs helps reduce by incorporating additional features into the mold design.

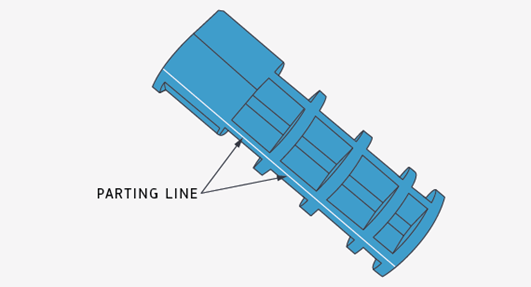

Parting Lines

Simplifying and minimizing parting lines in your design will help you get cleaner LSR parts as quickly as possible.

Undercuts

LSR can be molded to accommodate parts with undercuts, which are manually removed by a press operator. Mechanical tooling actions to release undercuts are selectively offered at Protolabs. LSR tends to tear fairly easily at sharp edges. In the making of interior features, it is very important to try to add fillets or radii to prevent tearing at what might be generally sharp edges, when using a manually removed undercut.

Overmolding and Insert Molding

LSR materials can also be used for overmolding and insert molding purposes. In fact, LSR materials are often used for overmolding, which allows an additional layer of resin to be added to an existing molded part to provide a combination of characteristics no single material can provide. One of the most common applications is to add a soft, functional, hand-friendly layer of rubber-like material, typically a thermoplastic elastomer, over a hard substrate. Another is to change or enhance the appearance or cosmetics of a part by overmolding material of a different color or finish to it. As an example, overmolding shows up on anything from medical devices and hand tools to toothbrushes and oven knobs. Most overmolding done on the above-mentioned items are a TPE or TPU material and not silicone.

Insert molding is used to add strength and durability to parts, usually by bolstering certain pivotal points on an LSR part with metal—a brass bearing journal, for example, or a stainless steel threaded insert—or a high-temperature plastic material. Because of the high-cure temperature of LSR molding, suggested plastic materials would be Valox, PEI (Ultem) or PEEK.

There usually needs to be mechanical bonding features when insert molding LSR onto other parts, because LSR generally does not chemically bond. Additionally, Protolabs does not allow the use of a primer to make a chemical bond.

For more detailed information on mechanical and chemical bonding, see the table at the bottom of this tech tip.

Part Ejection

Ejector pins are normally not used during LSR molding due to the flashy nature of the material. Thus, parts should be designed so they can be retained on one half of the mold when it is opened at the end of the molding cycle. The part is then manually de-molded, often with air assistance.