Nylon, also called Polyamide (PA) is a widely used polymer in the additive manufacturing sector. This thermoplastic is available in powder or filament form for technologies such as SLS, Multi Jet Fusion or FDM. These plastics are classified according to their chemical composition, and in particular, according to the number of carbon atoms they contain – the most well-known on the 3D printing market are undoubtedly PA12 and PA11, as well as PA6 for FDM. What are the characteristics of nylon when used for 3D printing? Who are the manufacturers on the market and what are the applications? Find out more in our complete guide below!

Nylon first appeared in 1935. It was developed by Wallace Carothers who then worked for the chemist DuPont, the material was marketed three years later in the form of a toothbrush! Nylon is mainly found in the textile industry thanks to its flexibility and resistance. It was used in 1940 for the first time in the production of women’s stockings. Later, it was adopted in the automotive industry due to its resistance and friction properties.

Nylon Filaments for FDM 3D printing

If we look at filaments, nylon is most often available with 6 carbon atoms, more commonly called PA6. It is a filament that has many interesting characteristics, including great flexibility, resistance to impact or abrasion. Additionally, its mechanical properties are quite close to ABS. However, note that nylon will require the presence of a heated plate inside the 3D printer (that can reach around 80°C) due to adhesion issues. It will also be necessary to take care of storage because it quickly absorbs the surrounding humidity (hygroscopic material) which could impact printing later. In terms of extrusion temperature, the 3D printer will have to rise to 250°C, or even 220°C for certain types of nylon.

Nylon filaments are a good alternative to polycarbonate because they are easier to print. They will have a better lifespan, therefore ideal for printing parts that need to be resistant. Therefore nylon is used to print tools, hinges or machine components that need good resistance.

Among the main manufacturers of nylon filaments, we find Taulman3D, XStrand, Neofil3D, and machine manufacturers like Zortrax and Ultimaker. Be aware that nylon can be reinforced with carbon fiber or fiberglass. On the price side, it takes between 25 € and 40 € depending on the brand for a classic reel (500 grams, diameter 1.75 mm); if you choose a composite material, the price can quickly climb around 60-70 €.

Polyamides in powder form

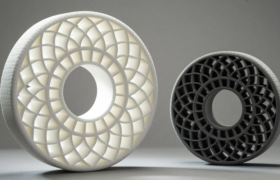

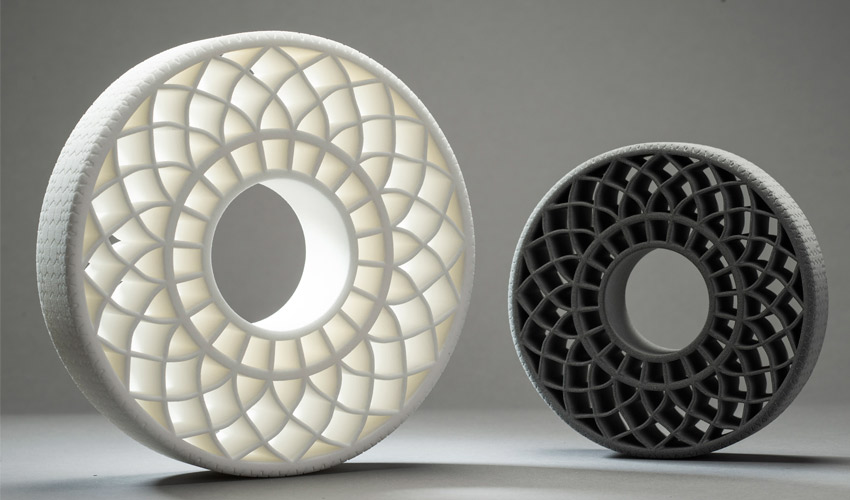

FDM is not the most widespread process for nylon 3D printing: selective laser sintering (SLS) is. Nylon will therefore be available in powder form, generally PA12 or PA11. Let’s start with PA12, the most widespread in the industry: it offers very high mechanical and thermal properties (high rigidity, extremely solid even at very low temperatures, resistant to stress, etc.) as well as resistance to various products and chemicals. Compared to filaments, it absorbs little moisture and is also very easy to process after printing (paint, dye, etc.). It is also biocompatible: it can be used to produce parts that will touch the skin, which makes it an interesting material for the medical sector, especially for the manufacture of prosthetic devices. PA12 is very popular for making gears, hinges, or even to replace certain plastics used in injection molding processes.

PA11 is also found on the additive manufacturing market. It is biosourced, mainly from castor oil while PA12 is derived from petroleum. We can therefore easily say that PA11 is more environmentally friendly. It shares the characteristics of PA12 with a few differences: PA11 has better thermal stability, greater resistance to light and UV, and a good elasticity. Parts 3D printed with this polyamide will also have a longer lifespan, making it an ideal material for producing end use parts or functional prototypes that incorporate important mechanical properties. It absorbs a little more moisture than PA12.

The French chemist Arkema is undoubtedly the biggest producer of PA11 powder today, marketed under the name Rilsan PA11, since the 1950s. The German company, BASF joined the race with its brand Ultrasint, compatible with HP Multi Jet Fusion machines and some models of SLS printers. The group also produces PA6. For PA12, we will find chemists like Arkema and Evonik while EOS, 3D Systems or Farsoon offer their own powder developed in partnership with chemists. Note that there are also new charged polyamide powders, based on carbon fibers or kevlar but also on glass beads for example.

Finally, the HP Multi Jet Fusion process is a large user of polyamides, whether PA12 or PA11. The special feature of HP technology is that it offers a higher recycling rate compared to conventional SLS technology, up to around 70% of the powder not used during 3D printing is then mixed to new polyamide powder, thus minimizing waste. Another interesting point is that HP now offers the possibility of dyeing polyamide powder during 3D printing with its range of 380/580 3D printers, enabling polychrome parts to be obtained.