Following our introduction of the different 3D printing technologies, today we will be talking about the metals used in 3D printing. To begin, it is important to note that metals are widely used in the aeronautics, automotive, and biomedical industry and use processes such as Laser Powder Bed Fusion (LPBF), Electron Beam Melting (EBM) or Directed Energy Deposition (DED).

Aluminum

This material is an excellent compromise between lightness and solidity. In addition to being resistant to corrosion, it can also be welded. Compared to steels, it is less resistant and more sensitive to high temperatures. It is mainly used in areas where weight is essential such as in mechanical parts of racecars, aeronautics, aerospace, bicycles, etc.

It is rarely present in a pure state and is found more often as an alloy with metals that improve its physical and mechanical properties, such as silicon and magnesium. A typical example is AISi10Mg Aluminum, which is proposed by the German manufacturer EOS in powder form. This makes it possible to manufacture solid and complex parts.

Aluminum Alloys

As mentioned, aluminum alloys are more often found than the pure form, and are traditionally used in many industrial, aerospace and automotive applications. Additionally, they possess high strength-to-weight ratios, and they also demonstrate good resistance to metal fatigue and corrosion.

Gallium

Even in research and development, gallium is used as an alloy with 25% indium, to print objects from small metal bubbles or from self-supporting metal cables to join electronic components, for example. What makes this alloy special is that not only can it melt at a low temperature of 85.46° F (29.7° C), the two metals also harden in air while the inside remains liquid, enabling the print to be flexible.

The price remains the main barrier when wanting to commercialize this material for 3D printing use. Here is a video made by a team of researchers at the University of North Carolina who are working on printing this material:

Steel

Being one of the most common metals in the industry for manufacturing all types of parts, it is no surprise that steel was the first metal used in 3D printing.

Stainless steel

Stainless steel is quite present in everyday life, mechanical industries, and medicine. It has good metal properties and makes it possible to obtain a polished and bright surface. Several players in additive manufacturing offer this material such as EOS, ProMetal or ExOne. Some of its properties include: hardness, tensile strength, formability and impact resistance.

It is also possible to print bronze or gold parts using stainless steel as a base material. The layers of stainless steel powder are coated with glue to inject bronze into the printing, for example.

Maraging Steels

The company EOS offers the Maraging Steel MS1 steel, which is used in the manufacturing of tools or molds, thanks to its strength and resistance to breakage.

Titanium

Titanium is the flagship of medicine and aerospace, thanks to its excellent composition of both strength and weight, in addition to its high resistance to corrosion and biocompatibility. All grades of Titanium exhibit extreme corrosion resistance, ductility, and weldability, although Grade One is relatively more formable than Grades Two, Three and Four. Grade Four is the strongest.

3D printing makes it easier to manufacture titanium parts and avoids the impurities obtained with traditional techniques during the welding phase. However, a major disadvantage of this material is its high cost, as it is around 50 times greater than steel.

Titanium Alloys

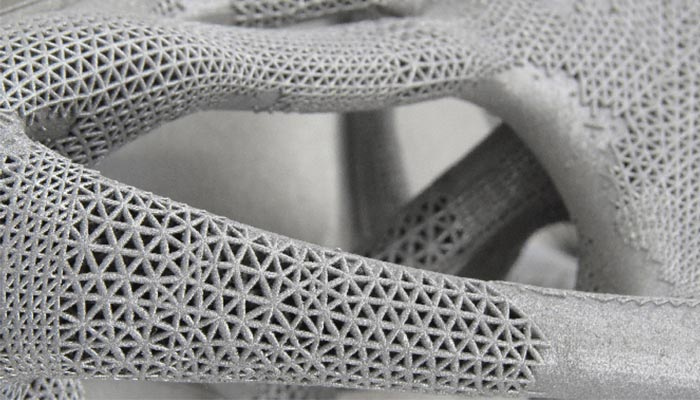

As with aluminum alloys, titanium alloys have improved mechanical properties and chemical behavior. They are used in additive manufacturing to produce a wide range of industrial components, including blades, fasteners, rings, discs, hubs and vessels. Titanium alloys are also used to produce high-performance race engine parts like gearboxes and connecting rods.

Cobalt-Chromium

Printed using the E-Beam (EBM) and DMLS techniques, cobalt alloys exhibit better quality than those obtained using traditional production methods, such as lost-wax casting.

Like titanium alloys, cobalt-chromium alloys, such as CoCrMo, are widely used in medicine for the manufacturing of prostheses in both orthopedics and odontology (thanks to its stiffness, smoothness, wear-resistant surface condition and lack of corrosion). In addition, the automotive and aerospace industries use some highly heat-resistant cobalt-chromium-molybdenum alloys.

EOS offers CobaltChrome MP1 and SP2 alloys that are resistant to high temperatures at 1,112° F (600° C). On the other hand, Arcam markets the ASTM F75, which is also widely used for the production of tools and molding.

Nickel-based alloys

Nickel chromium super-alloys like Inconel 718 and Inconel 625 produce strong, corrosion-resistant metal parts. These alloys are often used in high-stress, high-temperature aeronautical, petrochemical and auto racing environments. The mechanical properties of nickel-based alloys in AM, such as Inconel 625, are considerably enhanced by the use of significant amounts of nickel, chromium and molybdenum in the metal.

Precious Metals

We previously saw that it is possible to add glue to inject bronze and gold into a printed object made of steel. There is also another way of printing with these metals, which is through a molten metal cast. This cast is a mold made with lost wax, with the finishing being done by hand.

This method is widely used in jewelry and in the manufacturing of small objects. One of the problems and limitations to this molding is that you must take into account the thin shapes that need to be avoided, as well as ensuring that you have a minimum thickness of 0.8 mm to 1 mm for the walls must be respected.

The finishing phase is the key to a good surface rendering, especially for silver coins. With gold, it is possible to obtain different shades of colors (pink, white and yellow).

To wrap up, it is important to note that today it is possible to modify the atomic structure of the metal during printing. By doing this, you will have a more rapid and uniform solidification, which can result in a more rigid and resistant metal. For more information on metal 3D printing technologies read our full guide HERE.