In this section, we will be discussing different materials such as: ceramics, sand, organic materials, marble, stone, and wood. We hope you enjoy this installment on 3D printing materials!

Ceramics

Ceramics are used in medical, sanitary or industrial applications and is the flagship of tableware (kitchen and decoration), and is increasingly used in 3D printing.

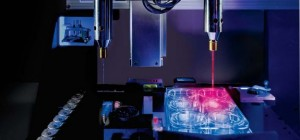

Ceramic objects can be printed using the technique of Selective Laser Sintering (SLS) from a previously compressed dry powder, or through solidification of the material in a liquid state. This is a process that resembles the FDM technique with a modified print head. Here is a video that shows the 3D impressions of a porcelain vase (source: Unfold)

On the market today, you can find several offers from EOS for the manufacturing of molds: The Ceramics 5.2, a silicate and aluminum sand that is very resistant to heat; the Quartz 4.2 and Quartz 5.6, phenolic resin-coated quartz sands that print complex shapes.

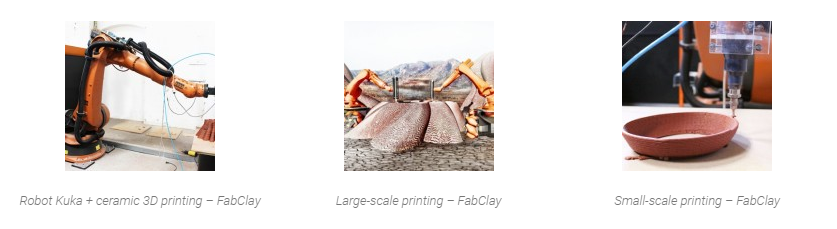

Fun fact: A group of researchers from the Institute for Advanced Architecture of Catalonia (IAAC) in Barcelona created the FabClay which helps explore a new way of looking at digital manufacturing processes. In addition, the ‘Kuka’ robot for 3D ceramics printing has obtained fairly good results.

Sand

Sand is used mainly for the manufacturing of foundry molds, but it can also be very useful in the field of architecture when combined with other materials (as we’ll see later). This material was first printed in 1999 by ExOne, which today offers the largest sand printer on the market, the S-Max, which can print part sup to 1800 x 1000 x 700mm.

Here is a video to help understand how the 3D printer works:

Another machine that was developed by a group of researchers from the Institute for Advanced Architecture of Catalonia (IAAC) was the Stone Spray Project, which works with both solar energy and beach sand that is mixed with a binder.

Here are some images of the results that were obtained with the machine:

Concrete

Using the same printing principle for ceramics can be used to print concrete or any other composite material that is made from a wet paste. The MIT Media Lab has developed a 3D printing machine made of large polyurethane parts where the concrete is cast, allowing the manufacturing of doors, windows, building walls, etc.

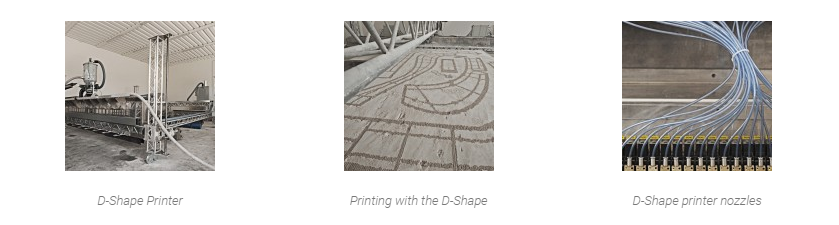

Another technology for printing whole buildings is artificial concrete, which was developed in Italy by Enrico Dini, founder of D-Shape. This machine was inspired by the technique of Stereolithography (SLA), but this time it uses sand. By replacing the UV with an inorganic binder, it gives the material the properties of marble.

Fun fact: The D-shape was integrated into the European Space Agency research for the design of a lunar space station printer on-site!

Marble

Thanks to the company MarbleEcoDesign, marble has finally been added to the list of 3D printing materials that can be used.

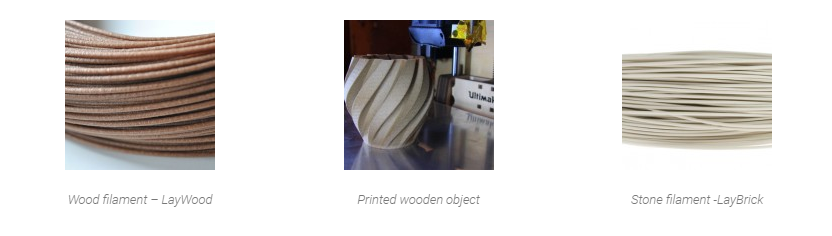

Wood and stone

Designed to be used with 3D printers that work using FDM, these materials are available as filaments. The wood (LayWood) is composed of recycled wood and apolymer-based inorganic binder. Stone filament (LayBrick) is composed of minerals that resemble chalk powder. But, the most innovation lies in the fact that the objects have the look (with different effects) and the smell of wood. And in the case of stone, one can obtain both surfaces as rough and varied depending on the temperature.

Organic materials

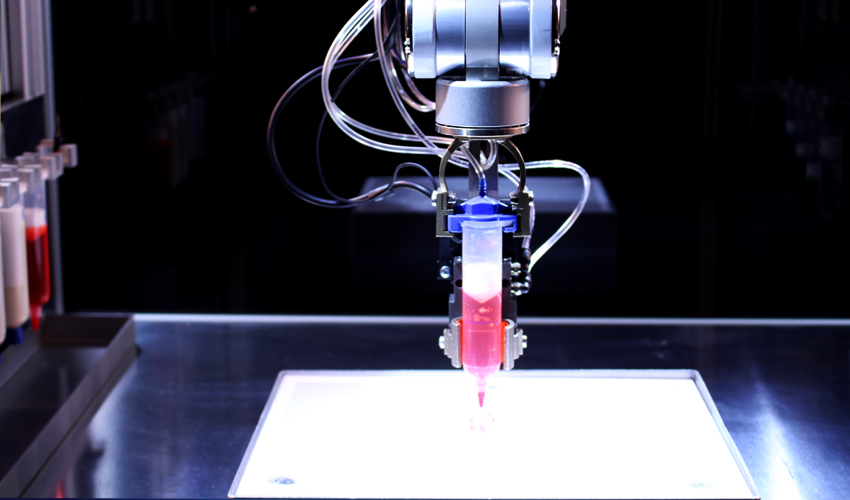

Today 3D printing has evolved to allow us to 3D print human tissue that is made from a gel structure, in which living cells are injected to begin the construction of the biological tissue. The limit to this technology is the constant supply of blood needed that allows the cells to remain alive during the printing.

The company that is pioneering this technology is Organovo with the NovoGen MMX BioPrinter, but there are also other companies such as envisionTEC and different universities that have machine models to meet this new trend. Overall, a very important trend for the future of transplants and for the pharmaceutical industry in general.

Waxes

Mainly used for foundry casting for mechanical parts, art pieces and odontology (for the manufacturing of jewelry), there are several types of waxes that are currently available on the market. The first is 3D Systems who offer the VisiJet Prowax, the VisiJet Hi-Cast and the VisiJet Dentcast Dental wax-up (for the ProJet 3500 and Project 5000 3D printers that operate on MultiJet technology). On the other hand we have Stratasys who markets the 3Z Model, the 3Z Lab Cast, the More Cast and the Indura Cast. For printing using the 3Z (Max, Lab, Studio, Pro) line of printers they use a technique that is similar to that of MultiJet. In addition, you can find machines and materials at EnvisionTec and at Objet (PolyJet technology).

A video to help you better understand the 3D Systems MultiJet process:

Edible materials

A recent trend in 3D printing, the new favorites are in the creation of chocolate, cheese and frosting foodstuffs that can be printed. The printing principle is based on FDM, with a syringe instead of a conventional extrusion head. Foods are not synthesized during printing and the machines are only used for the creation of complex decorations.