What is an STL file?

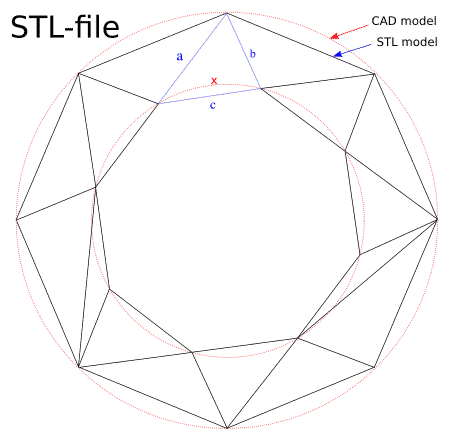

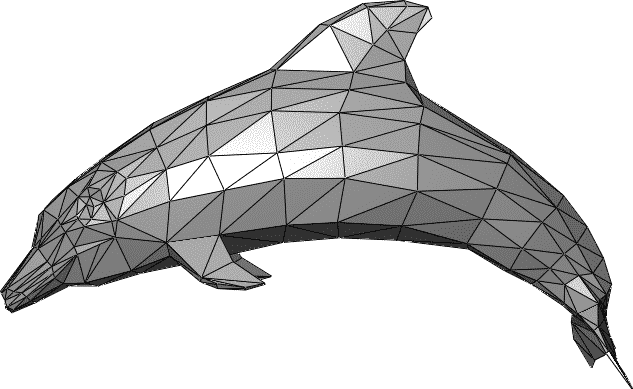

STL is a kind of file format widely used for rapid prototyping, 3D printing, and computer-aided manufacturing. It only describes the surface geometry of a three-dimensional object without any representation of color, texture or other common CAD model attributes.

The STL allows the 3D printer to interpret CAD model data and then to create a physical object. It represents the surface of the digital model as a mesh of triangles, and each triangle contains three elements: vertices, edges, and faces.

When it’s applied in 3D printing, the STL file is used in conjunction with a 3D slicer, enables the computer to communicate with the 3D printer hardware. To properly form a 3D volume, the surface represented by any STL files must be closed and connected, where every edge is part of exactly two triangles, and not self-intersecting.

The importance of using a correct STL file

We receive poorly exported STL files from time to time. For our customers, using a correct STL file will bring an obvious advantage: it saves the cost of a model revision service. A false STL file can lead to geometric inaccuracies, poor resolution, missing faces, etc. Most 3D printing servers will decline to print such an STL file directly, as they’re not willing to take the responsibility of printing failure caused not by them.

The most common STL errors

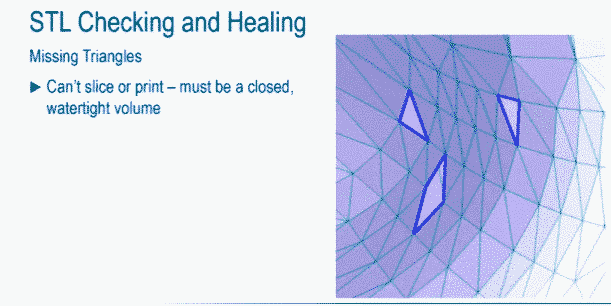

Holes or gaps in a mesh

Being a watertight solid volume is really the first requirement of all slicing algorithms. The 3D slicing and printing machine cannot work on this kind of model. This occurs when the adjacent triangles fail to share two common vertices.

Inverted Normals

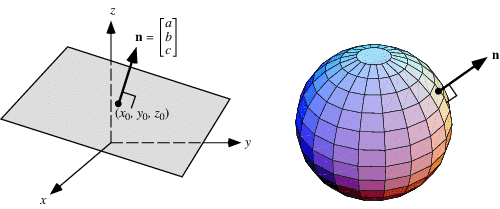

To illustrate this error, you should have a pre-knowledge of the normal vector. The normal vector is perpendicular to the surface at a given point. When normals are considered on closed surfaces, the inward-pointing normal (pointing towards the interior of the surface) and outward-pointing normal are usually distinguished.

As for additive manufacturing, each triangle in the STL file should have a correct normal vector to define which side of the triangle faces outward. Usually, the normals of triangles on the same faces should all be inward or outward, teaching the printer to add the material in the right way.

But in some cases, there exists an inverted normal, which confuses the printer in identifying the inside and the outside of the model, and so the model cannot be accurately sliced and printed.

Bad Edges

It happens when more than two bodies or faces share the same edge, or an extra surface is defined in the interior of the model. The former example will confuse the 3D printer whether to manifold the bodies/faces or not, while the latter one results in a meaningless laser path or machine path.

This error is not as severe as the above, seldom leading to slicing failure, but we still suggest you make a repairment, like adding the thickness of the edges for connection, or, increasing the clearance to 0.3 mm between the edges for disconnection.

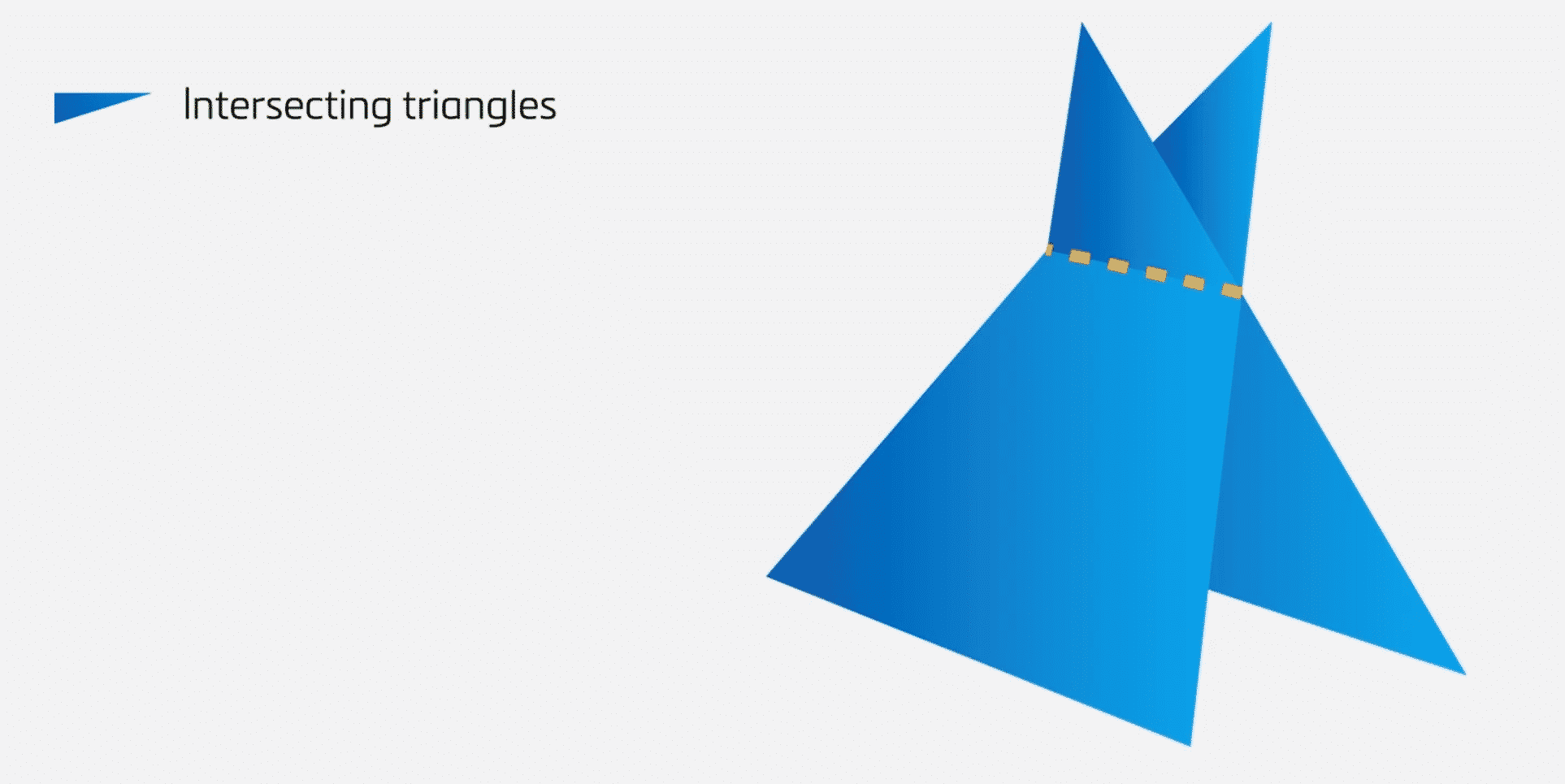

Intersecting or overlapping triangles

When two surfaces overlap or cross one another due to the complexity of the internal geometry, we call it intersecting or overlapping triangles. Intersecting faces usually lead to failures during slicing. If you input this STL file into an SLS printer, the laser will pass a location too many times and may change the property of the material; if you are operating an FDM machine, the filament will stack and cause a mess of your prints.

The good news is that you can easily repair such an error by remove or unify these triangles, or else it will inevitably add time and cost to the process.

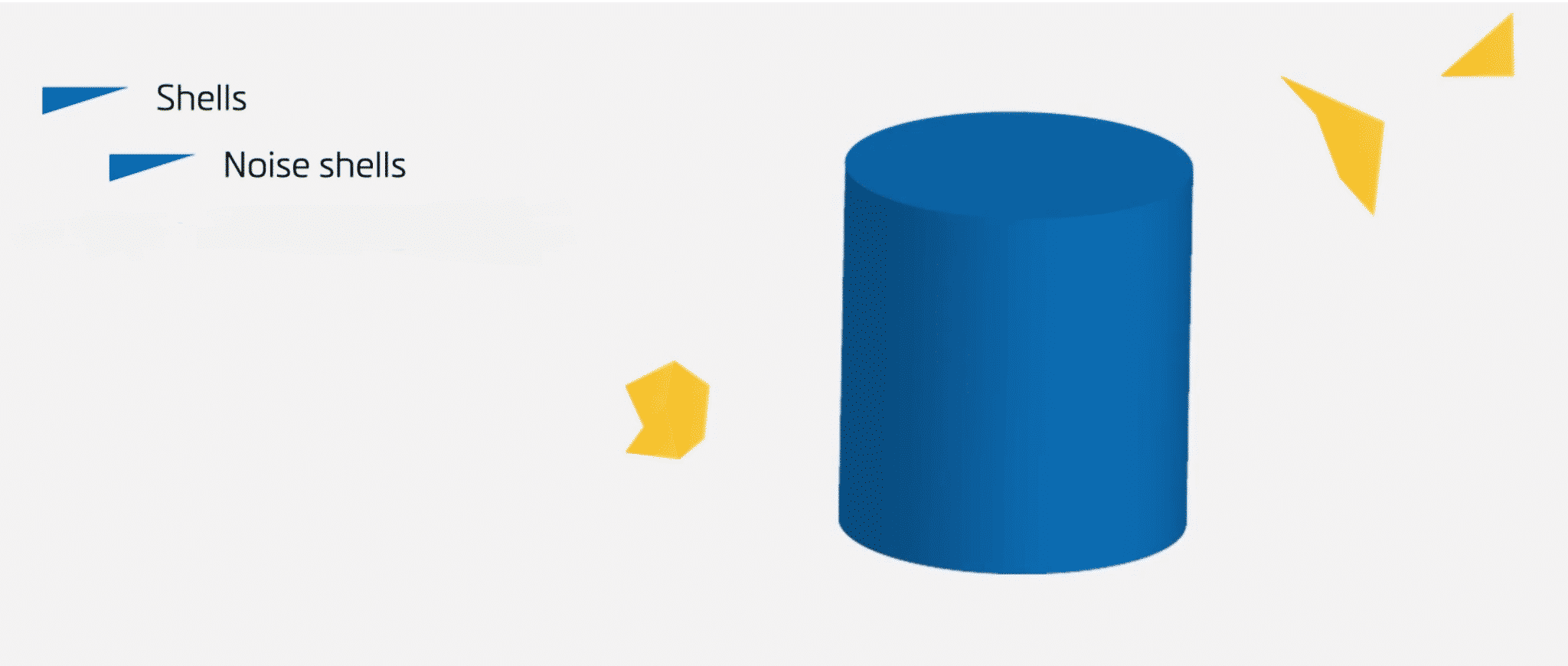

Noise Shell

Noise shells are those shells that are too small to build the outside layers of the prints, thus becoming redundant and useless. The repair software can easily analyze this kind of errors and remove them.

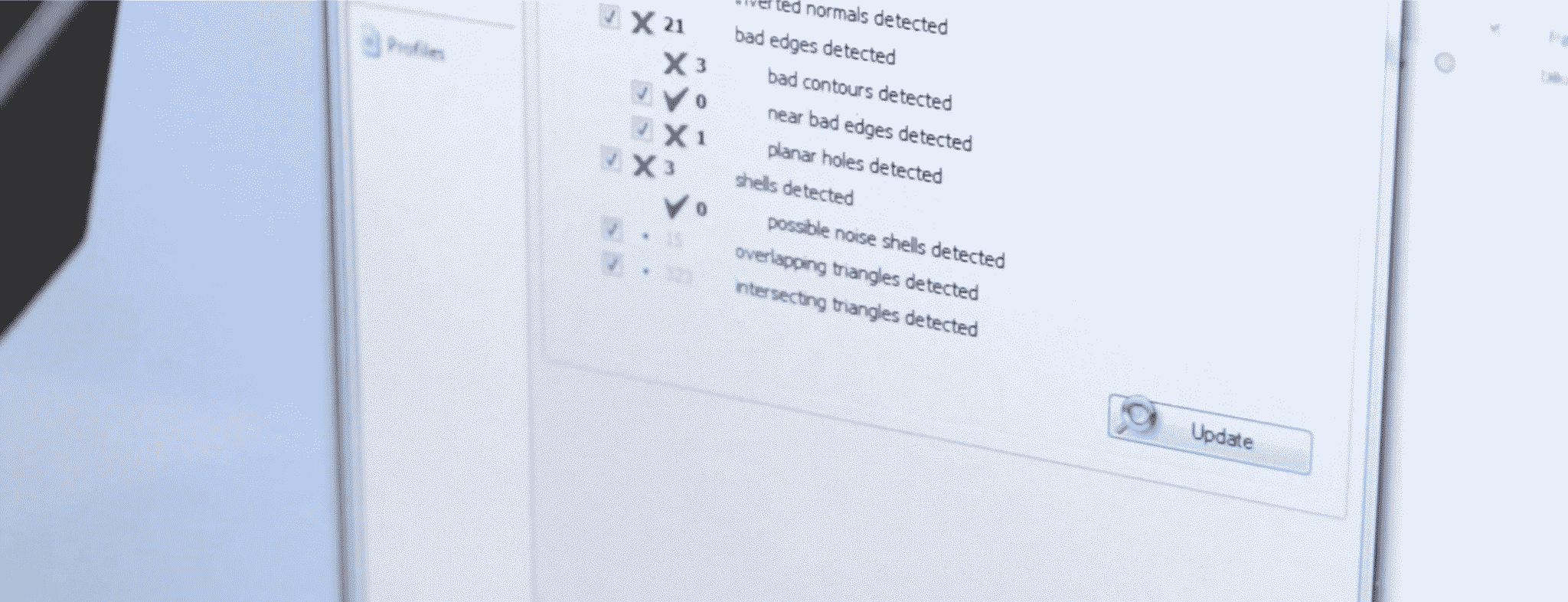

Recommended STL repairing tools

The best way to solve any issues with your models is definitely repairing the errors in the native CAD software before exporting them to STL. If it’s not an alternative, there are various kinds of STL repair tools for your convenience.

- Netfabb | Autodesk

- Meshmixer | Autodesk

- 3D Builder | Microsoft Corporation

- MakePrintable | MakePrintable