Prototypes help design teams make more informed decisions by obtaining invaluable data from the performance of, and the reaction to, those prototypes. The more data gathered at the design stage of the product development cycle, the better the chances of preventing product or manufacturing issues down the road.

Indeed accelerated prototyping has always been important in medical development, and especially now during the COVID-19 crisis as designers and engineers create critical medical products to fight the pandemic (see sidebar).

At FacFox, we produce prototypes for a range of medical devices and other Medtech products and assemblies. A well-thought-out manufacturing strategy greatly increases the chances that a product will pass strict regulatory and compliance standards, launch to the market on time, be accepted, perform reliably, and be profitable. Our services and quality processes ensure you get there faster by leveraging our decades of experience in medical device product development combined with the ability to quickly iterate on designs with our accelerated manufacturing processes.

Here are eight ways we can help improve your parts during medical device product development.

1. Use Design for Manufacturability Analysis

A common manufacturing method for end-use medical parts and components is low-volume injection molding, although functional medtech prototypes are also 3D printed and machined. At FacFox, our molding process starts with an online quote. Each quote comes with a free, automated, interactive design for manufacturability (DFM) analysis. Beyond the online interactive analysis, we have dedicated design review teams for free design consultation for all four of our manufacturing services: molding, machining, industrial-grade 3D printing (additive manufacturing), and sheet metal fabrication. Everything starts with your uploaded CAD model.

Additionally, regarding molding in the medtech world, sometimes you may find that a part that was originally designed to be 3D printed or CNC machined may need to be redesigned for injection molding. Our applications engineers are available for consultation on these types of redesigns. For customers who may need more support in the design process, FacFox offers Consultative Design for Manufacturability (CDFM), a consultative deep-dive into your product design with recommendations and insight on how to improve geometries to maximize function.

Our goal is to help save time and money—even if you need to make modifications you didn’t plan for—to avoid designs that are not manufacturable.

The next section dives deeper into molding for medical device and medtech parts and products.

2. Leverage Injection Molding for Medical Applications

In the highly regulated world of medicine and medical products, our medical molding service moves part and component design rapidly from prototype to production. This is especially important in this industry, where products need to pass rigorous testing from the development phase through commercialization. Our high-quality aluminum tooling, combined with automated DFM analysis, can quickly cut product development time, taking just days to cut a tool vs. steel tooling.

Along these lines, our quality control and tooling items include:

- ISO 13485 certification with a partner-registered facility, which is the quality management compliance standard for companies and organizations working in the medical device industry

- Process validation, which may be achievable by a standardized qualification package, industry-accepted protocol, or customer-defined

- Clean rooms—we have Class 8 rooms available with our strategic partner

- Steel tooling—we have P20 and hardened steel available with our strategic partner

Additionally, on the topic of tooling, our software program for mold flow analysis can help improve a medical part’s overall design through a number of ways, such as: aiding in the positioning of the gate or gates on your part; showing the position of knit lines, which allows you to improve your part’s cosmetic and physical properties; locating trouble spots that are hard to fill within your part; and identifying the proper material for your design.

At FacFox, companies have turned to us for recent medical-related projects such as:

- Lower volume or difficult-to-forecast products

- Early-in-development parts and products

- Components requiring complicated supply chains

- Projects in which design flexibility is needed all the way through development

- Parts in which early process lessons can benefit in a transfer to production

- Design verification testing, clinical trial submissions, and regulatory-body submissions.

3. Iterate Prototypes Rapidly with Multi-Cavity Tooling

Developing parts and devices for the medical industry is challenging because things move so quickly. This is especially true now during the COVID-19 crisis. Accordingly, you can take advantage of our family and multi-cavity tooling in injection molding so you can mold, in final, end-use material, multiple versions of the same prototype, then test those multiple versions, and move forward with the prototype version that succeeds.

In addition to the benefit of rapid iterations, using multi-cavity molds can also be an efficient way to boost production volume and reduce part cost. We have a design tip on multi-cavity molds that goes into more detail.

4. Consider 3D Printing in Metal for Complex Medical Parts

Direct metal laser sintering (DMLS) is a frequently used metal additive manufacturing technology with applications for the medical industry. There are several benefits to DMLS—including printing high-resolution parts to support metal instrumentation design, for example. Materials include stainless steel (17-4 PH & 316L), aluminum (AlSi10Mg), cobalt chrome (CoCr), Inconel (IN718), copper (CuNi2SiCr), and titanium (Ti-6Al-4V).

Consider surgical tools with ultrafine features and medical components with organic shapes. These devices may be designed for metal injection molding or casting, both of which have relatively high tooling costs and lead times that can span weeks. With DMLS, you can print a prototype surgical hand tool at the exact weight and strength of the final product and have it in a surgeon’s hands within days.

For DMLS projects, check out our design guidelines.

| MEDICAL MANUFACTURING INDUSTRY FIGHTS COVID-19 |

|---|

The manufacturing toolkit for medical applications outlined here takes on a greater urgency these days for those designers and engineers who work on medical device and medtech product development. At Protolabs, we’ve partnered for many years with medical companies so we’re especially proud to now work with our existing medtech customers as well as new customers to create medical products and devices to fight the COVID-19 pandemic. We’ve been deemed an essential business during this crisis so we remain open for business. This includes all eight of our manufacturing facilities in the U.S. Some of the medical applications we have recently produced parts for and can assist with include:

|

5. Choose Finishing Options for Molded Medical Parts

Medtech companies often leverage post-processing options for their molded medical parts. We offer a wide selection of finishing options for molding that strengthen parts, improve cosmetic appearance, and provide customization, among other benefits. These finishing processes include:

- Mold texturing

- Custom-color matching

- Threaded inserts

- Pad printing

- Heat Staking

- Laser Engraving

- Basic Assembly

Medical device company Hemosonics, for example, recently turned to FacFox for finishing options in addition to using our injection molding, 3D printing, and machining services. The company used heat staking and pad printing for its Quantra System blood analysis machine.

6. Use the Right Material for Medtech Parts

We have suitable, medical-grade material for most injection molding or 3D printing projects. Choosing the best material for your project means that your prototypes will match final parts as closely as possible.

We also offer custom-color matching on customer-supplied Pantone numbers and customer-supplied part samples. Customers with proprietary materials for final production, common in the medical industry, often want to select a material as similar as possible to their in-house material by providing a close match in elasticity, hardness, strength, and other critical characteristics.

For help deciding which material or color will work best for your job, you can also consult with one of our application engineers.

Common materials for medical applications:

- High-temp Plastics

PEEK and PEI (Ultem) offer high-temperature resistance, creep resistance, and are suited for applications that require sterilization. For example, parts for a medical device may have to tolerate the extreme high heat of an autoclave or harsh chemical sterilization between uses.

- Medical-grade Silicone Rubber

Dow Corning’s QP1-250, for example, has excellent thermal, chemical, and electrical resistance and biocompatibility traits for injection molding. It can usually be used in applications that require skin contact.

- Carbon RPU and FPU

Carbon DLS uses rigid and semi-rigid polyurethane materials to build functional 3D-printed parts ideal for late-stage prototyping or end-use devices. Also suitable for highly complex parts.

- Micro-Resolution ABS-Like

MicroFine™ (green and gray) is an exclusive FacFox material. Print complex 3D-printed parts, like precision instrumentation and diagnostic components, with micro-sized features as small as 0.0025 in. MicroFine™ mimics a typical ABS plastic and enables great design freedom.

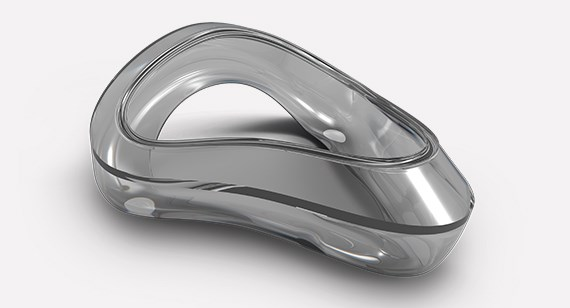

- Transparent ABS-Like and PC-Like

3D printing materials like ABS-Like Translucent/Clear (WaterShed XC 11122) and PC-Like Translucent/Clear (Accura 60) can be finished to show functional clarity in microfluidic parts and transparent components like lenses and housings, which are used in a variety of medical applications.

- Medical Alloys

Among machined, 3D-printed, and sheet metal, there are more than 20 metal material options for medical components, instrumentation, and other applications. Metals like titanium and Inconel have attributes such as temperature resistance, while various stainless-steel materials have corrosion resistance and strength.

This material comparison guide can help you make the best choice.

7. Ensure your Manufacturer Has a Proven Quality System

Medical manufacturers navigate many challenging quality checks and regulatory approvals before a product hits the market. Our quality systems for molding and 3D printing continue throughout our entire manufacturing process. While they share similarities, each service has unique quality measures.

For injection molding, several quality-assurance steps span the molding process:

- Bar codes on all work orders keep everything organized and improve traceability

- Tight part-number and material controls ensure material requirements are met

- Thermoplastic molding resins are dried to specifications in the calibrated drying equipment

- Dimensional quality inspections are conducted at the start of orders and during manufacturing, are documented electronically, and become part of the manufacturing record

- In-process visual inspections can be conducted on an hourly basis to ensure parts match initial samples and workmanship standards

- Press settings are documented for future production runs

- Pressure and temperature controls are maintained for each shot in the molding process

- Fill, hold, and pressure studies conducted for production runs via scientific molding methodology

Quality systems for industrial-grade 3D printing drive part consistency and repeatability:

- Additive manufacturing instructions are sent to software-enabled 3D printers

- Before the build begins, process engineers verify and prep the material using an extensive checklist covering loading, unloading, and cleaning, which safeguards against mistakes.

- Temperatures during the build are monitored and adjusted accordingly

- Final parts are digitally tracked and have any required finishing or post-processing options performed before moving to inspection stations

- Overall, FacFox is ISO 9001-certified as a quality system for all 3D printing services, plus AS9100-certified for selective laser sintering, Multi Jet Fusion, and DMLS processes.

This blog series shows a more complete look at our quality system, which begins the minute you upload files to our quoting system.

8. Fast-Track Quality Inspections

Inspections are all about part conformity. Our injection molding inspection reports are customized according to what service and inspection level are needed. In injection molding, a blend of statistical and periodic sampling on part cosmetics and dimensions is used to best ensure the conformance of those parts. Inspections are completed by quality control personnel and a calibration program is in place for all measurement equipment.

We conduct additional inspection reporting to support critical dimension verification and quality documentation requirements. An enhanced digital inspection option, which helps verify up to 12 measurements, such as ID/OD (inside and outside diameters) plane-to-plane, and hole locations, can be administered in our metrology lab. A high-speed 3D scanner provides a color map with a direct CAD-scan comparison for additional quality reporting.

If an even more in-depth report is required, our metrology lab can generate a conventional inspection report through a third party to support first article inspection (FAI) requirements. The report verifies all part dimensions, including non-critical dimensions, and work for all geometric dimensioning and tolerancing (GD&T) measurement types.

Inspection reports for 3D printing are available upon request. We can even accommodate inspection reports to AS9102 standards. Additionally, we test tensile strength and hardness on a sampling of final parts in inspection stations. Plus, an in-house engineer tests metal 3D-printed parts for porosity and grain structure.

For additional help, feel free to contact an applications engineer at info@facfox.com. To get your design project started today, simply upload a 3D CAD model and receive an interactive quote within hours.