Product designers build strength into their injection-molded parts in different ways and for different reasons. Dissecting part application is a good first step in determining if additional strength should get designed into a part. How will customers be using your product and what environment will it live in? You may need parts that can withstand repetitive impact, resist wear, or bear heavy loads. It may be as simple as integrating ribs or gussets into your design, or a more complicated combination of design elements involving support features, material, wall thickness, and more. Finding the proper balance of design considerations will help address your part’s need for strength and stability.

Plastic Rib Design

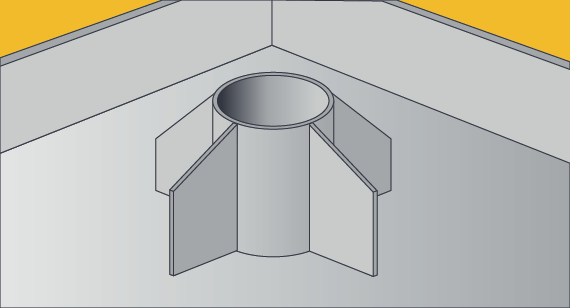

Ribs are thin, wall-like features typically designed into the geometry of a part to add internal support to walls or other features like bosses. In a similar fashion, gussets are support features that reinforce areas such as walls or bosses to the floor. Just as bridge beams and columns are supported at their vertex with gussets to add critical strength to the structure, the same concept applies to plastic injection molding.

Reinforce Bosses and Walls with Gussets

Both ribs and gussets provide stability in parts without having to increase wall thickness, and are particularly beneficial for parts with already thin walls that could potentially be compromised by end-user wear and tear. It’s important to note that ribs and gussets should be no more than 60 percent of nominal wall thickness. These features are kept thinner than the primary walls in an effort to avoid overly thick sections where ribs and gussets intersect with the wall. When you have a surplus of material meeting at internal rib-to-wall intersections, sink marks can appear on the visible side of the part.

Product designers can play with different ribbed formations to create square, rectangle, diamond, triangle, or honeycomb patterns that stiffen the part. A pattern of ribs is equivalent to coring out unneeded material, leaving only the rib support system—it also reduces the weight and cost of the part. But, remember to not remove surfaces and features that interface with the other parts in the product assembly.

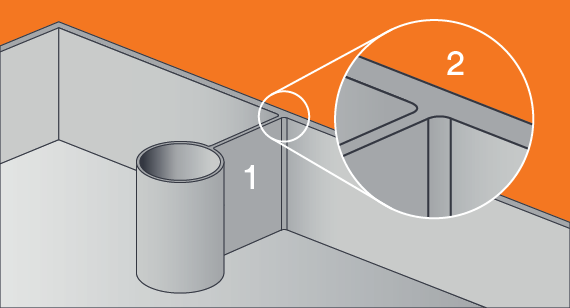

Fillets and Radii

Because sharp corners weaken parts, fillets—curved faces where ribs meet walls—can also be designed into part geometry to eliminate additional mechanical stress concentrations on a finished part. Much like gussets, a fillet that is too small will fail to accomplish its task of stress reduction, but a fillet that is too large can once again create sink. Identifying the proper size and locations of fillets (and ribs and gussets) are important. When adding a fillet to the inside of a corner, also add a radius to the outside of the corner, if possible. If the risk of sink is too high in some sections, then other strength-building methods should be considered.

Durable Thermoplastics

Material selection also plays a role in the stiffness, durability, toughness and other characteristics of parts; balancing the relationship between those material properties and part functionality is key. For example, product designers can choose a thermoplastic resin that will make a stiff, rigid part, but if its application demands a high degree of impact resistance, the brittleness of an inflexible part may cause it to break. Material properties differ from resin to resin—here’s a glance at some of our more frequently used resins:

- ABS is a good, stable consumer-grade resin that is tough and impact-resistant in daily use environments. It’s commonly used in housings for remote controls, battery-powered tools, and body panels for monitors, printers, and copiers. There may be chemical resistance concerns with ABS.

- Polycarbonate is more impact-resistant than ABS, and good for lenses and parts that require more shine. It is susceptible to stress cracking, and risks crazing/hazing due to chemical compatibility concerns.

- Unfilled nylon is pliable and impact-resistant with good lubricity for wear. Glass-fiber filler increases nylon’s stiffness and compressive strength, but the material becomes more brittle on impact. Glass-fiber filler helps increase heat deflection temperature.

- Acetal is an excellent self-lubricating bearing material with great wear properties and good stiffness. It’s not good for cosmetic parts or parts that require pad printing, paint or decals.

- TPEs are great for dust seals and padding corners for impact resistance, and used in overmolding applications for grip features. They’re not always good in dynamic applications; static applications are best. There may be chemical resistance concerns with TPE.

Changing the performance of a base resin often requires additives such as glass fibers, glass beads, or talc. Glass fiber fillers increase the compressive strength of a material and also help increase the thermal deflection of a part allowing the part to perform in environments or applications that base resin would not find acceptable. Glass beads increase the thermal deflection but may make the material a bit more brittle as the beads stack like a ball pit, rather than a hay stack with glass fiber. Glass beads can also be used to help reduce internal stress that may be caused by glass fiber fillers. Talc is often used to increase stiffness to a material but typically creates a weaker impact resistance. So we need to think of additives as helping but with risk. Understanding those risks and weighing them against the added benefit is part of the material testing and selection process.

Wall Thickness

Sometimes, if you want to add strength to a part, you just have to increase overall wall thickness. FacFox provides a list of recommended wall thicknesses based on resin type to help design parts that are neither too thin nor too thick. In general terms, small parts can process at .040in (1mm) reasonably well. But once you start getting into palm or hand-sized parts, 0.080 in. (2mm) nominal wall should be considered. Designing larger parts may require more wall thickness for flow/filling the cavity under reduced stress but attention needs to be paid to parts greater than 0.120 in. (3mm). Often, once parts reach 0.150 in. (3.8mm), they can become so thick that the cross section when cooling can start to sink on itself and other manufacturing processes or assistance may need to be considered. Thermoplastic molding in general is quite stable and repetitive from 0.060 in. (1.5mm) to 0.100 (2.5mm). The larger that parts get, the more attention needs to be paid to ribs, gussets, materials, and other factors that improve strength. As usual, our applications engineers are available to discuss part geometry and design, and make sure to look for the interactive moldability analysis that comes with every quoted part at FacFox.