3D printing is not just a new tool for developing and producing goods – embracing the technology can have a major impact on how the company operates, provides value to its customers and makes a profit.

Today’s article will explore 5 powerful 3D printing-enabled business models, alongside their benefits and real-life examples.

1. On-demand manufacturing

Striking a balance between demand and supply is challenging. That’s why suppliers use sophisticated algorithms to predict how much of their products will be needed, at a certain time and a certain place, to meet an uncertain demand.

But what if you could turn the supply-demand equation on its head? Instead of producing in anticipation of demand, what if you could produce on-demand, after the customer has committed to buying the product?

This is the promise of on-demand manufacturing.

Today’s on-demand manufacturing business model emphasises the speed of delivery and the ability to produce parts at the point of need. This is appealing to customers because you get exactly what you need, exactly when you need it.

3D printing is one of the technologies that makes on-demand manufacturing a possibility. With no tooling required for 3D printing, lead times for small batches can be significantly shortened.

It means that if a company wants to produce a few dozen, or even hundreds of parts, it is easier to achieve with AM. A company doesn’t have to wait weeks to manufacture tools, like moulds for traditional manufacturing. It can just create a design file, send it directly to a 3D printer and have a part printed within several hours or days.

Spotlight: Spare parts

Let’s take spare parts 3D printing as an example.

Imagine a system where customers, or suppliers, order spare parts from a manufacturer’s web page. Within hours, a nearby 3D printing service bureau has downloaded the files, printed the parts and sent them to the customer. Alternatively, the customer prints parts on their own equipment, eliminating shipping costs, tariffs and delays.

For industry, producing spare parts faster means increased machine uptime and fewer production disruptions. For consumers, it means less waiting time for someone to repair a car or appliance.

To demonstrate the benefits of on-demand 3D printing, American manufacturer, Moog, teamed up with Microsoft, ST Engineering and Air New Zealand, for a practical demonstration in the aerospace industry.

For this project, a Boeing 777-300 aircraft, bound for Los Angeles Airport after departing from Auckland, carried out a proof of concept, centred around the simulation of a broken cabin part.

Upon reaching cruising altitude, the aircrew notified maintenance in Auckland that they needed to replace a Business Premier bumper part – which sits between seat and monitor to ensure the seat isn’t damaged when the screen is pushed back to a default position.

The maintenance team used its access to a digital catalogue of parts, uploaded by Air New Zealand’s MRO provider, Singapore-based ST Engineering, and ordered a replacement component.

ST Engineering identified where the spare part could be 3D printed in Los Angeles and sent directly to the airport.

Using localised 3D printing allowed the part to be produced well before the aircraft landed. Within 30 minutes of being on the tarmac, the part was replaced, and the plane could complete its further three scheduled trips before returning to Auckland.

According to Moog, if this spare part was sourced in a traditional way, it would have been a 44-day lead time and it would have cost roughly 30,000 US dollars in revenue loss.

Admittedly, not all parts will benefit from on-demand 3D printing.

According to recent research, most companies can benefit from a hybrid strategy, where on-demand spare parts 3D printing is combined with holding parts in inventory. In the majority of cases, a part that seldom breaks down, or is simple enough to be printed in a few hours, could be a good candidate for on-demand 3D printing.

The research also found that by using the hybrid approach, the average cost savings is around 5 per cent compared to stocking everything, with maximum cost savings reaching up to 40 per cent.

2. Manufacturing as a service

The digitisation of manufacturing has brought about new service-based business models for manufacturers.

One of them is Manufacturing as a Service (MaaS). This model hinges on a sharing of manufacturing infrastructure, where equipment, and other manufacturing capacity, is networked to enable more efficient production.

With MaaS, a customer can send an order for a part, and based on workload, materials, workforce availability, location and scale, the network will dynamically route the order to a given facility, or set of facilities, to most efficiently fulfil the request.

MaaS is becoming increasingly popular, fuelled by the rise of digital manufacturing.

3D printing has become one of the key pillars supporting the MaaS model. As a digital manufacturing technology, 3D printing allows parts to be produced from a digital file, and the majority of its workflow is data-driven.

This enables workflow digitisation, crucial for MaaS businesses.

Finally, 3D printing also allows for more production flexibility and economic on-demand production of small batches and one-offs, which is a typical value proposition of MaaS companies.

Examples of MaaS companies using 3D printing

Xometry operates an extensive Partner Network of manufacturers, many of them small and medium-sized businesses. This broadens the reach for more local demand as well as ensuring access to the specified manufacturing technology. In addition to 3D printing, the Partner Network also offers CNC machining, sheet metal fabrication and injection moulding.

Between 15 per cent and 20 per cent of 3D-printed parts, ordered through the Xometry platform, are end-use parts for low-volume production needs.

Techniplas Prime service, a subsidiary of US-based automotive manufacturing service provider, Techniplas, is also offering a 3D printing-powered MaaS platform.

Today, Techniplas enjoys collaborative relationships with 25 Prime partners, which it envisioned as a 3D printing-based ‘e-manufacturing platform’ for car manufacturers. Since its launch in 2018, Prime is said to have helped Techniplas produce more than 40 million parts.

The examples above demonstrate that 3D printing allows MaaS companies to provide accessibility to a wider spectrum of technologies. This, in turn, helps these companies to expand their value proposition and facilitate the transition to digital manufacturing.

3. Supply chain consolidation

As the manufacturing environment becomes more volatile and uncertain, businesses are looking to reduce the complexity of their supply chains.

The opportunity now exists to simplify the supply chain by using 3D printing to manufacture end-use parts in-house.

The benefits of doing this are so huge that, according to one 2018 Gartner study, 38 per cent of supply chain managers are already using 3D printing and 47 per cent plan to use it in the next 2 years.

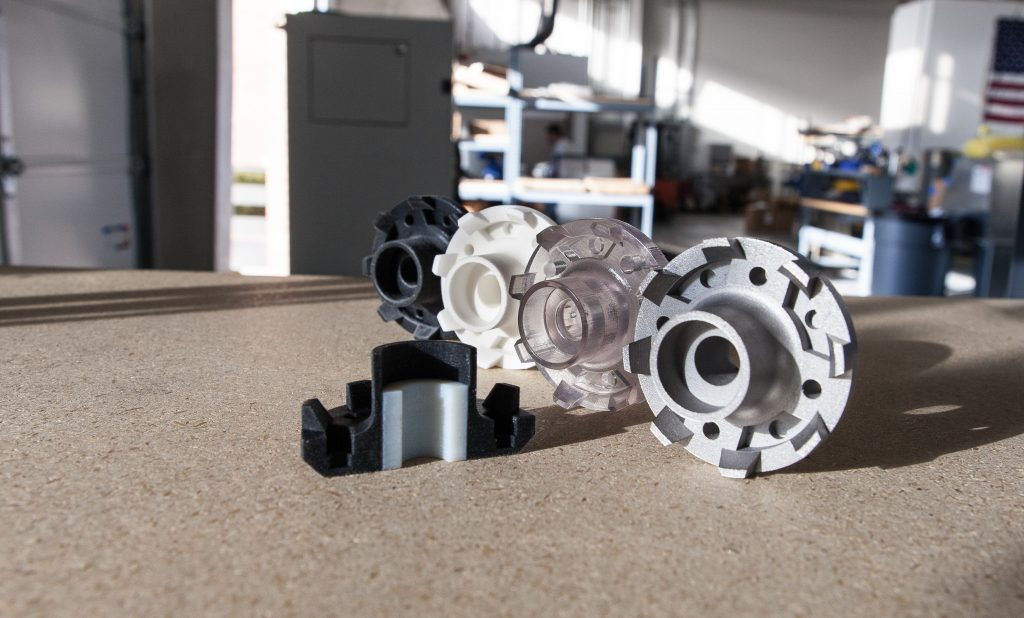

3D printing is uniquely capable of producing complex geometries that can’t be manufactured using traditional methods. This capability could be used, for example, to reduce parts in an assembly.

An assembly that would normally require many parts fabricated as separate components and then brought together can be additively manufactured as a single unit, even if the geometry is very complex. This process is also known as part consolidation.

Part consolidation helps to reduce the number of parts that need to be procured, thus lowering the supply chain complexity.

The reduced supply chain complexity decreases the risk of supply chain disruption. For example, you can circumvent the risk that your supplier can no longer supply the part in question. This supplier risk is multiplied by the number of parts in the assembly. So if you’re able to print multiple parts as a single unit, using 3D printing, the chances of encountering this issue greatly decrease.

How Jabil and GE use 3D printing to consolidate their supply chains

One company using 3D printing to consolidate supply chain is Jabil. For example, Jabil was able to redesign a fan within a cooling system, originally made up of as many as 73 labour-intensive and time-consuming parts, and 3D print it as a single part.

According to Jabil, shrinking a component from 73 individual parts to 1 part has a massive trickle-down effect throughout its entire supply chain. The part reduction has led to a leaner supply chain with a more reliable and consistent production level.

Another great example of part consolidation is GE’s Catalyst Advanced Turboprop engine, which was reduced from a whopping 855 parts to a mere 12.

GE says that to make these parts the ordinary way, it typically needs 10 to 15 suppliers. Now, by 3D printing them, the company can streamline its supply chains.

As Mohammad Ehteshami, the former head of GE Additive, noted: ‘Today, there are hundreds of big planes flying between cities around the world and carrying machine components. Tomorrow, you won’t need to do all of that. You’ll just print what you need’.

4. Mass customisation

In today’s consumer landscape, consumers are demanding more customised and personalised experiences.

Essentially, the mass customisation model entails creating one-off products that are precisely adjusted to the needs or whims of individual buyers.

3D printing allows companies to explore this business model by providing a more viable solution to producing customised products.

Unlike conventional techniques, which would require substantial investment into tooling for customised parts, 3D printing only requires uploading customised digital designs of a product, or its part, into a 3D printer.

Frequently, the technology is also used to create disposable customised moulds, which would typically be cost and time-prohibitive with traditional manufacturing.

Creating personalised goods with 3D printing

This approach is often used to produce jewellery with custom designs. For example, jewellery company, American Pearl, offers a ‘Jewelry Replicator’ service on its website, which allows customers not only to choose from a list of different metals, but also to customise a piece of jewellery with a personal engraving.

Based on a chosen design, the company then creates a design file and 3D prints it in thermoplastic wax.

The customer’s chosen metal is then poured into this digitally-designed mould. Once it hardens, the shopper’s gemstones are added and set by an expert jeweller.

The company claims that the finished jewellery will not only match the consumer’s exact specifications but will also be delivered in 3 to 4 days. Competitors, who charge more for the same product, can take weeks to complete it.

Some footwear companies have also started investigating mass customisation, enabled by 3D printing. For example, Wiivv’s business model is centred around sandals with custom-fit 3D-printed insoles.

Allowing this is Wiivv Technology, which digitally maps each foot with over 200 points to create a 3D-printable file of an insole that is unique to each foot.

Large brands are also looking into ways to adapt and provide customers with more personalised products. Gillette is one such company that has recently launched a razor blade customisation service powered by 3D printing.

With the mass customisation trend growing, 3D printing is poised to become one of the key technologies helping companies to capitalise on this trend.

5. Direct to consumer business model

The Direct-to-Consumer (D2C) strategy is fast becoming a popular route for brands to enter the market directly – instead of through a middle-man entity.

3D printing can help companies adopting this model to create products faster, and often cheaper, than with traditional mass-manufacturing techniques.

Take, for example, light manufacturer, Gantri, which provides a platform for designers to realise their ideas using its proprietary 3D printing process and delivers these designs directly to the customer.

In so doing, the firm aims to enable designers to bypass numerous hurdles in order to get their ideas to market.

Gantri estimated that traditional manufacturing of 1,000 pieces of a specific design, the tooling, combined with materials, engineering, testing and logistics, would rack up $100,000 in costs. This is why most items are produced in much larger batches than 1,000 and why there is such a large barrier to entry, for both manufacturers and designers.

‘Traditional manufacturing requires scale to be efficient, while 3D printing can meet or exceed quality/efficiency goals with the first unit’, Gantri writes in its blog.

3D printing opens up the possibility to forgo such investment and allows designers collaborating with Gantri to bring new designs to market, faster and cheaper.

Reportedly, 3D printing lamps and other lighting decor items helps Gantri to reduce lead time for designers, from an average of 18 months to about 3 weeks, and also cuts down on expenses.

The people behind Gantri are convinced that 3D printing is the future of the industry. For example, the technology can adapt to the changing customer tastes and trends with no problem.

In the dental industry, there is a new crop of companies using 3D printing to manufacture invisible teeth straightening devices, called clear aligners, which are then sent directly to consumers.

With the likes of SmileDirectClub and Candid, such companies want to provide an alternative to the quite expensive Invisalign aligners and cut down on pricey visits to orthodontists’ offices.

Without 3D printing, the business model adopted by these dental companies would likely fail, as it would have been almost impossible to produce individualised clear aligners at high volume with traditional techniques.

3D printing powers new business models

3D printing is not only becoming a new manufacturing tool, but it also enables businesses to create new business models that were previously either not feasible or not economically viable.

With on-demand production, 3D printing allows companies to satisfy the demand for certain parts, without having to consider the high costs of mass-production. This makes the company more agile.

Furthermore, it enables a co-creating process between customers and companies, resulting in a customised product.

Finally, 3D printing unlocks the possibility to consolidate the supply chain and allows companies to produce low to mid volumes of parts faster when using MaaS networks.

Considering these benefits, companies in many industries are likely to adapt their business models in the coming years to accommodate greater use of 3D printing, ultimately creating more nimble and responsive operations.

Source: https://amfg.ai/2019/11/29/5-examples-of-how-3d-printing-is-creating-new-business-models/