In spare parts management, the ultimate goal is to strike the balance between the cost of spare parts production, lead time and the volume of parts that must be kept in stock. One technology, helping both manufacturers and suppliers to reach this goal, is 3D printing.

As a digital manufacturing technology, 3D printing enables some spare parts to be stored in a virtual inventory and produced at the point of need, decreasing storage costs and improving service. With fewer fixed costs, compared to traditional technologies, 3D printing also proves more cost-effective for low-volume production.

It’s no surprise, therefore, that 33 per cent of companies surveyed by EY believes that 3D printing of spare parts enables a more efficient after-sales market, with an additional 26 per cent stating that the technology can reduce logistics efforts and inventories.

Today we take a look at the key benefits of 3D printing for spare parts, dive into the most exciting examples of the technology in action and share some tips on how you can start integrating 3D printing for spare parts into your organisation.

Spare Parts – A Changing Landscape

Currently, spare parts manufacturers are faced with a range of challenges stemming primarily from the production and storage of spare parts.

The cost of ordering spare parts is one such issue. In traditional manufacturing, to decrease the total cost per part, most things are produced in volume.

Volume manufacturing allows companies to amortise fixed costs, like tool manufacturing and setup costs, over a large number of parts. But spare parts are often produced in a much smaller volume, which means the total cost for such parts will increase.

Another issue in the traditional manufacturing of spare parts is long lead time. Finding the right spare part and then sending it to a client on the other side of the world, sometimes takes weeks, which negatively impacts customer satisfaction.

In some cases, manufacturers choose to stop providing some spare parts at all, leaving their customers empty-handed.

Furthermore, companies often have difficulties in determining how much inventory they should store. Maintaining warehouses full of stock is, in itself, a costly expenditure and only more so in the case of excess inventory.

However, with the advent of 3D printing, a lot of these issues can be successfully addressed.

How can 3D printing help solve challenges in the spare parts industry?

Economic low-volume production

3D printing has lower fixed costs of production, compared to traditional manufacturing processes, like injection moulding and vacuum forming. Since the 3D printing process is highly automated, it doesn’t require expensive tooling and generally has a lower cost associated with setting up a piece of production equipment.

Lower fixed costs give 3D printing an economic advantage when producing smaller volumes of parts.

Digital inventory: 3D printing parts on demand

When it comes to spare parts, companies face the challenge of balancing the investment of holding a high number of spare parts as inventory and the ability to meet the demand of the customer on time.

3D printing enables OEMs to rethink their approach to how they store parts, facilitating the shift towards digital inventory. The key reason for this is that 3D printing enables you to produce parts directly from a digital design file, without using any tooling, like moulds.

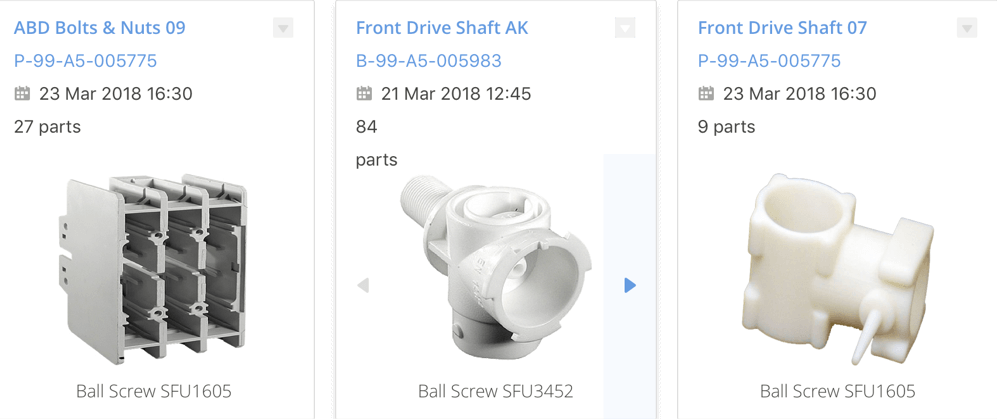

With digital inventory, some spare parts, particularly lower-demand parts, like obsolete components, can be redesigned for 3D printing and stored in a virtual parts catalogue, freeing up space in a warehouse.

When the part is needed, you can just find it in your digital inventory, send the design to a 3D printer and have it ready within several hours or days.

The ability to manufacture parts at the point of need indicates a shift from ‘make-to-stock’ to a more sustainable ‘make-to-order’ model for low volumes of spare parts. This provides a significant benefit for OEMs and suppliers – not least by reducing the number of parts stored in warehouses, and thereby decreasing inventory costs.

Faster lead times

With traditional manufacturing methods, lead times are often measured in months, due to the need to design and create a tool and set up a production line. 3D printing, on the other hand, offers much shorter lead times.

For example, a small aluminium bracket can be produced within a few days using DMLS technology, compared to at least 12 weeks it would require to produce it using extrusion and metal bending processes.

Furthermore, when a small number of obsolete parts needs to be replaced and there are no spare parts available, reverse engineering and 3D printing is arguably a perfect combination.

3D scanning creates a 3D printable digital model of a spare part, which is then sent to a 3D printer and produced in a much faster time frame. By adopting this process, suppliers and manufacturers can greatly improve their flexibility and business agility.

Challenges in Adopting 3D Printing for Spare Parts

Although the benefits of using 3D printing for spare parts are widely recognised, bringing the technology into a streamlined supply chain does not come without challenges.

Process repeatability is among the biggest concerns for many OEMs and suppliers.

The challenge here, therefore, is to set quality standards for spare parts and ensure that 3D-printed parts match these standards and industry specifications.

Dedicated software will play a key role in ensuring that standards are met. For example, Manufacturing Execution System software, developed for 3D printing, ensures process repeatability, by logging and tracking every stage of the production workflow.

There are also legal barriers, in the form of Intellectual Property (IP) and copyright, that need to be resolved.

As 3D printing moves manufacturing towards a digitally-driven supply chain, there still is uncertainty regarding IP and how the designs of parts, provided by suppliers, should be protected by copyright.

Before 3D printing is widely adopted within the spare parts industry, both suppliers and OEMs, respectively, must establish the security of their intellectual property.

5 Examples of Using 3D Printing for Spare Parts

1. Localised, on-demand 3D printing of aircraft spare parts

To showcase the benefits of on-demand 3D printing, American manufacturer, Moog, teamed up with Microsoft, ST Engineering and Air New Zealand, for a practical demonstration in the aerospace industry.

For this project, a Boeing 777-300 aircraft, bound for Los Angeles Airport after departing from Auckland, carried out a proof of concept, centred around the simulation of a broken cabin part.

Upon reaching cruising altitude, the aircrew notified maintenance in Auckland that they needed to replace a Business Premier bumper part – which sits between seat and monitor to ensure the seat isn’t damaged when the screen is pushed back to a default position.

The maintenance team used its access to a digital catalogue of parts, uploaded by Air New Zealand’s MRO provider, Singapore-based ST Engineering, and ordered a replacement component.

ST Engineering identified where the spare part could be 3D printed in Los Angeles and sent directly to the airport.

Localised 3D printing allowed the part to be produced well before the aircraft landed. Within 30 minutes of being on the tarmac, the part was replaced, and the plane could complete its further three scheduled trips before returning to Auckland.

According to Moog, if this spare part had been sourced in a traditional way, it would have been a 44-day lead time, and it would have cost roughly 30,000 US dollars in revenue loss.

2. Whirlpool establishes a digital inventory to optimise its spare parts system

To make spare parts supply more efficient, the international household appliance manufacturer, Whirlpool, has partnered with Spare Parts 3D, a provider of digital inventory solutions.

Together, the companies have committed to digitising Whirlpool’s parts catalogue to overcome part obsolescence and shortage issues.

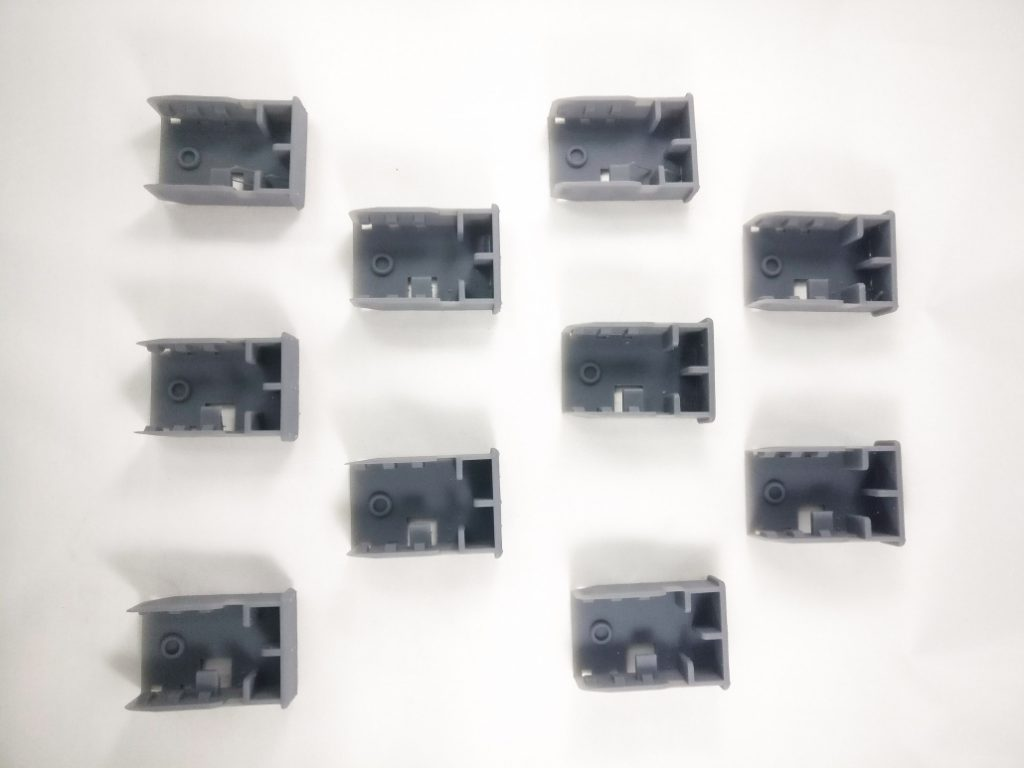

In Whirlpool’s catalogue,150 parts have been reviewed and for each of these parts, the Spare Parts 3D team tried different 3D printing technologies and materials.

The three methods that were selected by the company are FDM, SLA and HP Multi Jet Fusion (MJF). Materials used across these platforms for Whirlpool parts cover ABS, ABS V0, PA12, a rubber-like resin and PP-like resins.

The first part to pass all internal verification is a push-button made using PA12 on an MJF system.

Both companies are now looking to further expand the pool of components suitable for 3D printing. One important outcome of this collaboration is increased part availability, which has a significant impact on customer care.

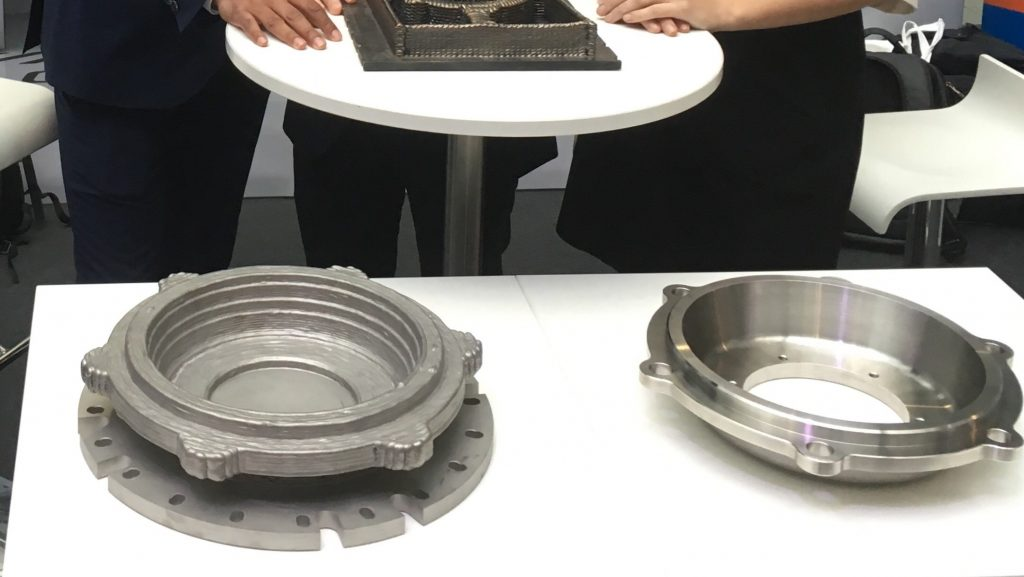

3. Deutsche Bahn is using 3D printing to reduce vehicle downtime

The German railway company, Deutsche Bahn, has been an early adopter of 3D printing for spare parts. Over the past few years, Deutsche Bahn has identified more than 100 use cases that can benefit from 3D printing. Most parts are availability-relevant, meaning that they can be difficult to procure, causing a months-long vehicle downtime.

One example of such a part involves a wheelset bearing cover for a Class 294 locomotive. This model was put into service in the 1960s and ‘70s, and spare parts for some components, like this cover, are missing.

Traditionally, Deutsche Bahn would need to have a new part produced, using a casting process. However, this method typically involves high minimum purchase quantities, and part delivery could take several months.

AM appeared as a natural alternative, as it was able to create this part faster and on-demand. The company turned to a service bureau, which 3D-printed a bearing cover using Wire Arc Additive Manufacturing (WAAM) technology. The WAAM process uses wire as a raw material. The wire is fed through a nozzle and welded, layer by layer, into the final workpiece.

The part, which weighs 13 kg, was printed in just 7 hours, providing Deutsche Bahn with benefits like increased part availability and considerably lower manufacturing costs.

4. 3D printing metal spare parts for beverage filling plants

Jung & Co. Gerätebau GmbH is a Germany-based manufacturer that specialises in stainless steel components. The company is using 3D printing to manufacture spare parts on demand, with one example being a can filler valve, for the beverage filler plant.

The traditionally manufactured can filler valve consists of 7 assemblies plus seals and screw connections. Manufacturing this valve takes 8 weeks or more, including procuring the required cast part.

Previously, the company kept the replacement for this part in storage, to be able to quickly provide it in the case of a failure.

However, the switch to metal 3D printing has enabled Jung & Co. to rethink its approach to the production of the valve.

Redesigning the valve for 3D printing and manufacturing it on a laser-based 3D printer allowed the company to achieve several benefits. First, 3D printing made it possible to manufacture the entire can filler valve in one operation, eliminating the assembly step. The redesigned valve is also 35 per cent lighter than the original assembly.

Shorter lead time is another benefit. For the beverage filling plants, the time from requesting and receiving a replacement part is critical. Profitability quickly diminishes when a plant must be shut down, and an hour of lost production may cost from around 4,000 to around 30,000 euros.

With 3D printing, the valve can be produced in one week – 8 times faster than with conventional methods – which, for beverage plants, means the possibility to significantly reduce costly downtime.

Finally, the 3D-printed can filler valve is also cheaper than a conventional alternative, and it no longer needs to be purchased in advance and kept in storage.

5. Porsche: 3D printing spare parts for classic cars

The division of Porsche Classic supplies parts for its vintage and out-of-production models and is using 3D printing to produce rare, low-volume spare parts for its older vehicles.

Many of these parts are no longer in production, and the tooling required to manufacture them either don’t exist or are in poor condition. Manufacturing new tooling aids with traditional methods is inherently cost-prohibitive, particularly considering the low volumes in question.

To solve these challenges, Porsche Classic has begun to 3D print these parts (in metal and plastic) on demand.

The advantage is that parts can be made without any additional tools and only when needed, helping Porsche to save on tooling and storage costs associated with making these spares using conventional methods.

3D printing parts that are rarely ordered or have stopped being produced is a growing trend within the automotive supply chain. Mercedes-Benz Trucks, Volkswagen and BMW are also embracing 3D printing for this application to cut costs, increase operational efficiency and optimise inventory.

Outsourcing or 3D Printing Spare Parts In-House?

As manufacturers increasingly adopt AM systems in-house, many may wish to consider establishing an in-house AM facility for spare parts, rather than procuring them. However, when considering whether to implement such a strategy, manufacturers must consider several factors, such as volumes of production, budget and timeline for implementing 3D printing.

If only small volumes of spare parts are to be produced, companies do not necessarily need to invest in 3D printers. With the growing number of 3D printing bureaus, manufacturers can easily have their spare parts 3D printed externally.

Generally, the choice of whether to outsource or produce spare parts in-house greatly depends on the extent to which a company would like to integrate AM into its workflow.

Integrating 3D printing for spare parts into your company

That said, when adopting 3D printing for in-house spare parts production, there are a few tips to follow to make the journey smoother.

A company should start small so 3D printing can help solve problems in the supply chain immediately. This will require a company to assess technical printability and economic viability to first identify which spare parts can, and should, be 3D printed.

This assessment should be based on technical details such as size, material and complexity. Typically, it makes sense to 3D print smaller parts with complex structures, although the possibilities for printing large components are expanding.

Economic reasons must also be factored in, such as the cost of downtime if that specific part isn’t available.

Starting from small projects will serve as a launchpad for further integration of 3D printing into your supply chain processes.

Building a digital supply network and developing a roadmap for the full integration of spare parts 3D printing will be the next steps that will help you scale and maximise the benefits of 3D printing in the supply chain.

Increasing supply chain flexibility

Spare parts 3D printing is unlocking a new business model for manufacturers and suppliers alike. Printing spare parts, rather than keeping them in an inventory, can decrease costs, improve parts availability and minimise a company’s dependency on the supply chain through localised production.

But to reap the full benefits of spare parts 3D printing, companies must adopt the right approach and tools, like digital inventory. This will help them make the transition to a new business model easier and open the door to a more flexible, demand-driven supply chain.